MOF/PIM-1 in-situ crosslinked matrix membrane and preparation method thereof

A PIM-1, in-situ cross-linking technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

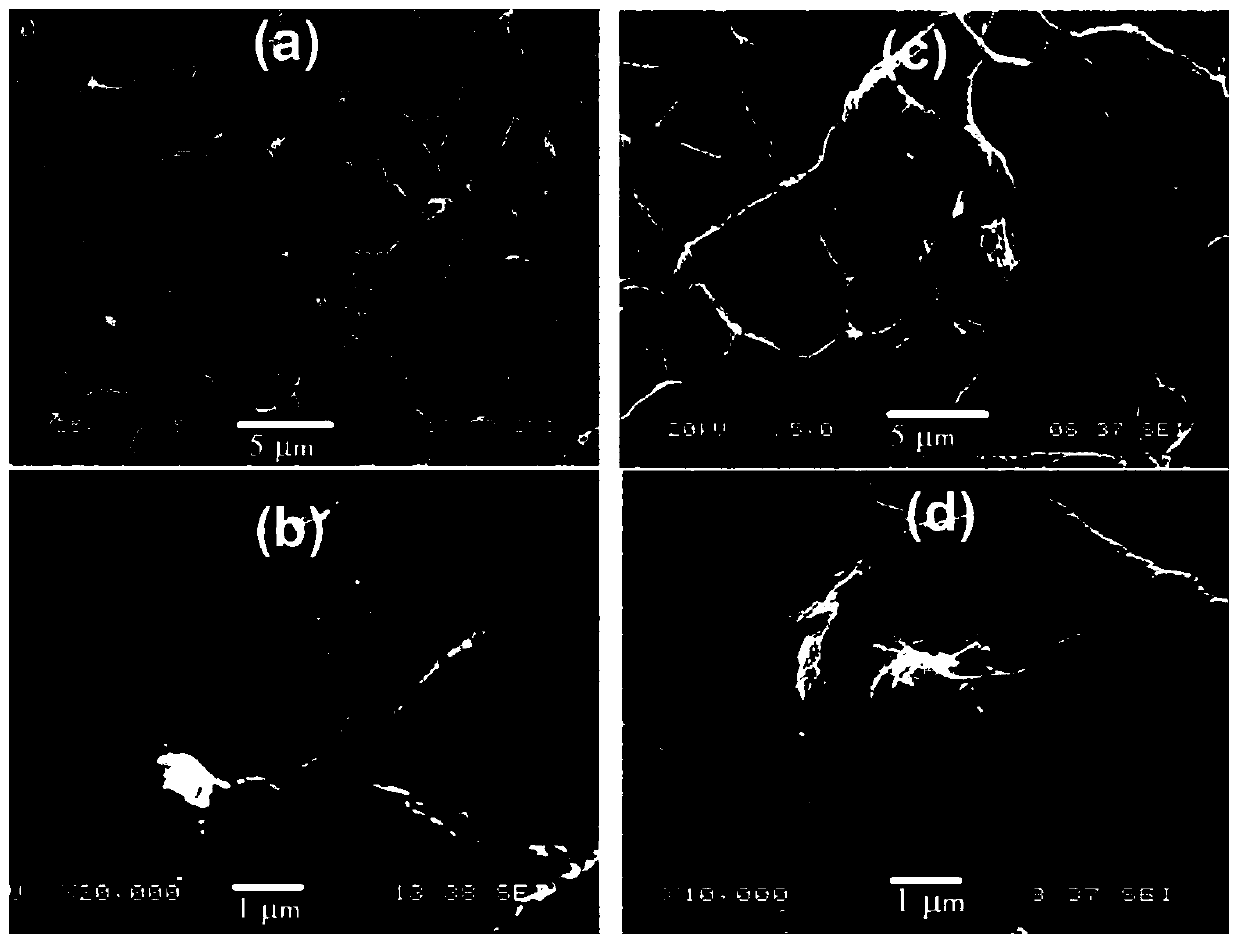

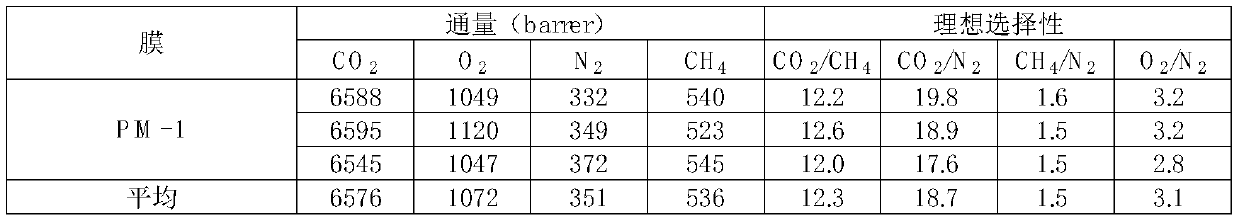

[0027] Example 1: Set up a reflux device containing a three-necked flask. In a nitrogen atmosphere, 3.4gTTSBI, 2gDCTB and 4.14g anhydrous K 2 CO 3 Put it into a three-necked flask, add 20ml of NMP, stir at room temperature for 3 minutes, then add 10ml of toluene, immediately put it in a 160°C oil bath for 40 minutes, pour the solution obtained after the reaction into 200ml of methanol, stir for 2 hours, and use a pore size of Suction filter with 0.45μm nylon membrane, dry the obtained filter cake at 60°C for 6h, then dissolve the dried powder in 100ml of chloroform, stir for 2h, centrifuge, dissolve the bottom precipitate in 400ml of methanol, stir After 2 hours, the PIM-1 powder was obtained by suction filtration, and finally washed twice with deionized water, acetone, and dioxane in sequence, and dried to obtain fluorescent yellow PIM-1 powder. Dissolve 0.72g of PIM-1 powder in 10ml of chloroform and sonicate for half an hour to obtain a viscous solution, pour the solution ...

Embodiment 2

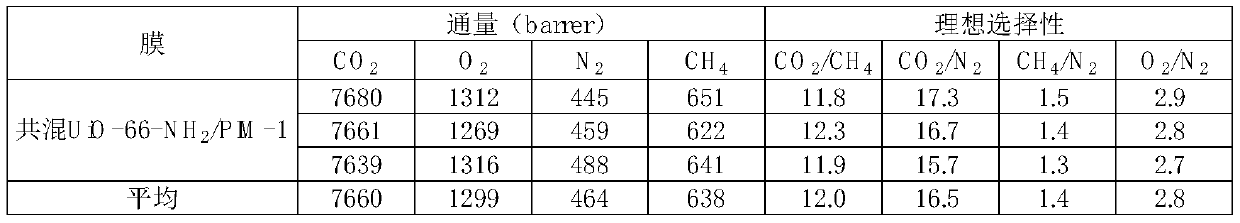

[0031] Embodiment 2: set up the reflux device that contains three-necked flask, in nitrogen atmosphere, with 3.4gTTSBI, 2gDCTB and 4.14g anhydrous K 2 CO 3 Put it into a three-necked flask, add 20ml of NMP, stir at room temperature for 3 minutes, then add 10ml of toluene, immediately put it in a 160°C oil bath for 40 minutes, pour the solution obtained after the reaction into 200ml of methanol, stir for 2 hours, and use a pore size of Suction filter with 0.45μm nylon membrane, dry the obtained filter cake at 60°C for 6h, then dissolve the dried powder in 100ml of chloroform, stir for 2h, centrifuge, dissolve the bottom precipitate in 400ml of methanol, stir After 2 hours, the PIM-1 powder was obtained by suction filtration, and finally washed twice with deionized water, acetone, and dioxane in sequence, and dried to obtain fluorescent yellow PIM-1 powder. 0.81g 2-aminoterephthalic acid, 1.06gZrCl 4 , 5ml of formic acid and 50ml of DMF were mixed and dissolved, stirred at roo...

Embodiment 3

[0036] Embodiment 3: 0.81g2-aminoterephthalic acid, 1.06gZrCl 4, 5ml of formic acid and 50ml of DMF were mixed and dissolved, stirred at room temperature for 3 hours, then the solution was transferred to a reaction kettle, and heated in an oven at 120°C for 24 hours to obtain a reaction mixture, and the bottom centrifuged product obtained by centrifugation was washed 4 times with methanol , and then activated in a vacuum oven at 120 °C for 24 hours to obtain UiO-66-NH 2 . Take 0.7 g of UiO-66-NH 2 Put into DMF (50mL), then add monomer and catalyst for PIM-1 polymerization, including DCTB (1.0g, 5.0mmol), TTSBI (1.7g, 5.0mmol) and K 2 CO 3 (2.1 g, 10.0 mmol). The reaction was carried out at 70°C for 24h, and the cross-linked UiO-66-NH 2 The yellow mixture with PIM-1 which precipitated at the bottom of the flask was filtered and washed with methanol (twice) and acetone (twice) to remove any residual catalyst and unreacted monomer. The product was dispersed in chloroform to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com