Preparation method of oil/water double-layer gel with high interfacial effect and product and application of preparation method

A double-layer gel and interface technology, which is applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems of complex preparation process, low universality, and restrictions on the industrial application of oil/water double-layer gel, and achieve the goal of preparation method Simple, high universality, high application value and practical operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) 0.4g zwitterion 3-(1-(4-vinylbenzyl)-1H-imidazol-3-ium)propane-1-sulfonate (VBIPS), 0.003g photoinitiator (2-hydroxy -4'-(2-hydroxyethoxy)-2-methylpropiophenone) and 0.006g N,N-methylenebisacrylamide (MBAA) were dissolved in 0.32g deionized water, and nitrogen was blown to remove oxygen to obtain Aqueous phase reaction solution;

[0042] (2) 9g butyl acrylate (BA), 0.04g ethylene glycol dimethacrylate (EGDMA), 0.025g photoinitiator 2,2-diethoxyacetophenone, 0.3g KH570 modified nanometer Silicon oxide is mixed evenly to obtain an oil phase reaction liquid;

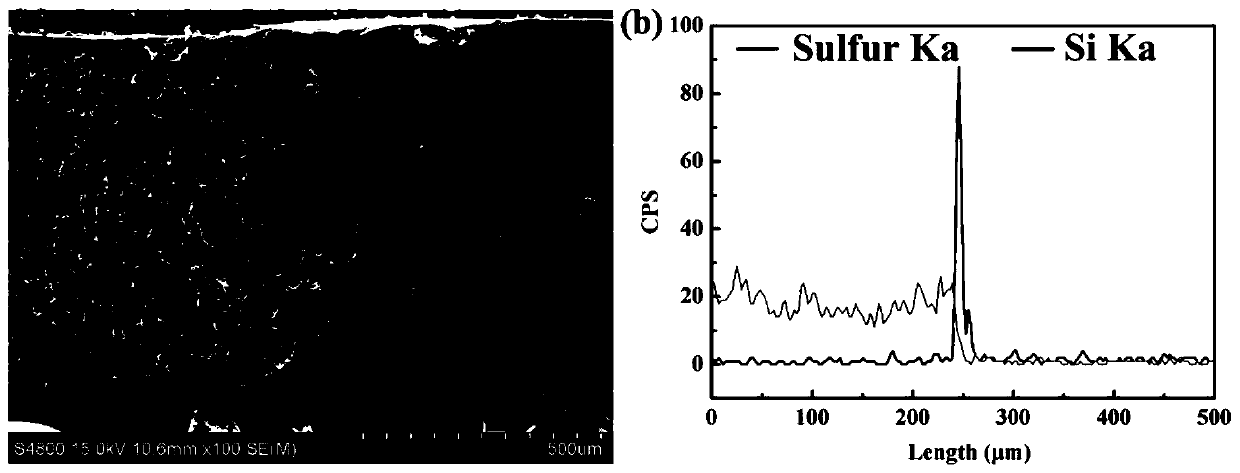

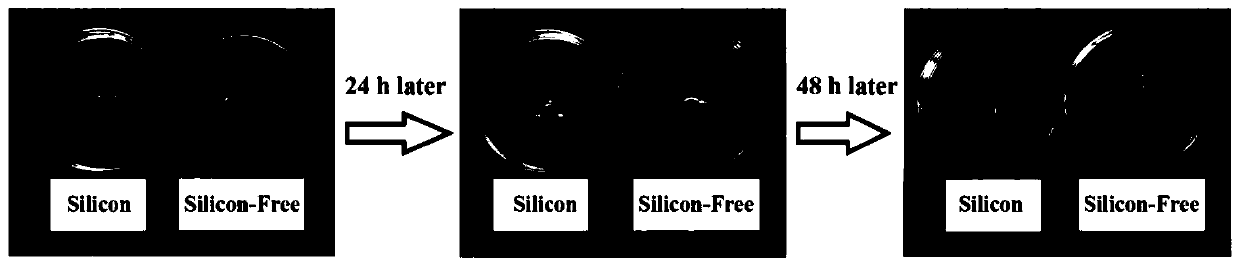

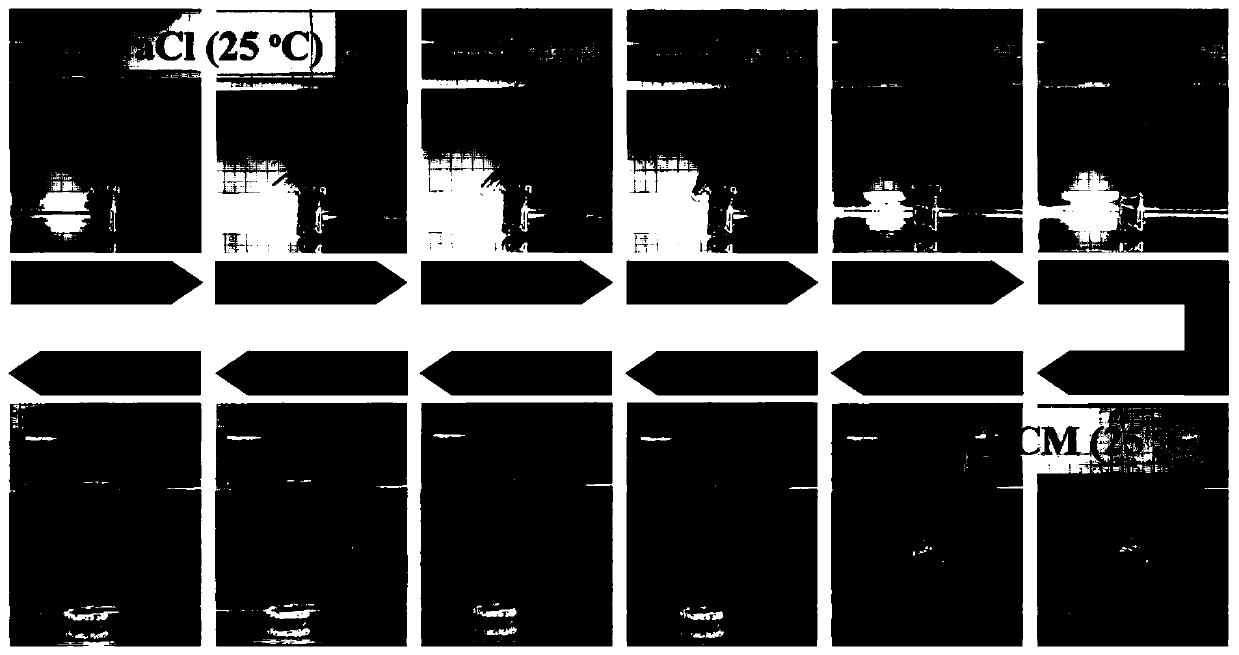

[0043] (3) First inject the water phase reaction solution prepared in step (1) into the mold, then inject the oil phase reaction solution prepared in step (2) into the mold with a syringe, and the mold consists of two pieces of 5 × 5cm quartz Glass is sandwiched with a silica gel sheet with a thickness of 1 mm, and it is left to stand for 12 hours. After the KH570-modified nano-silica is uniformly distributed a...

Embodiment 2

[0052] (1) Dissolve 0.4g of zwitterionic VBIPS, 0.006g of N,N-methylenebisacrylamide (MBAA) and 0.002g of ammonium persulfate (APS) in 0.32g of deionized water, and blow nitrogen to remove oxygen to obtain the aqueous phase The reaction solution;

[0053] (2) 6g butyl acrylate (BA), 0.036g ethylene glycol dimethacrylate (EGDMA), 0.108g azobisisobutyronitrile (AIBN) and 0.3g KH570 modified nano-silica were mixed evenly, Obtain an oil phase reaction solution;

[0054] (3) First inject the water phase reaction solution prepared in step (1) into the mold, then inject the oil phase reaction solution prepared in step (2) into the mold with a syringe, and the mold consists of two pieces of 5 × 5cm quartz The glass is sandwiched by a silica gel sheet with a thickness of 1mm, and it is left to stand for 12 hours. After the nano-silica modified by KH570 is evenly distributed at the interface of the oil-water phase, the temperature is raised to 60°C for 2 hours, and the polyVBIPS-polyBA...

Embodiment 3

[0056] (1) 0.4g zwitterion 3-(1-(4-vinylbenzyl)-1H-imidazol-3-ium)propane-1-sulfonate (VBIPS), 0.003g photoinitiator 2-hydroxy- 4'-(2-hydroxyethoxy)-2-methylpropiophenone and 0.006g N,N-methylenebisacrylamide (MBAA) were dissolved in 0.32g deionized water, and the water phase was obtained after blowing nitrogen to remove oxygen The reaction solution;

[0057] (2) 9g butyl acrylate (BA), 0.04g ethylene glycol dimethacrylate (EGDMA), 0.025g photoinitiator (2,2-diethoxyacetophenone) and 0.3g KH570 modified Nano-silica is mixed evenly to obtain an oil phase reaction liquid;

[0058] (3) First inject the water phase reaction solution prepared in step (1) into the mold, then inject the oil phase reaction solution prepared in step (2) into the mold with a syringe, and the mold consists of two pieces of 5 × 5cm quartz It is composed of a silica gel sheet with a thickness of 1 mm between glass, and it is left to stand for 12 hours. After the nano-silica modified by KH590 is evenly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com