Reinforced and toughened ultra-low temperature resistant nylon composite material and preparation method and application thereof

A nylon composite material, strengthening and toughening technology, applied in the field of polymer materials, can solve the problems of decreased compatibility, decreased toughness, and high glass transition temperature, and achieves prevention of poor interfacial compatibility, strong interfacial bonding, Evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

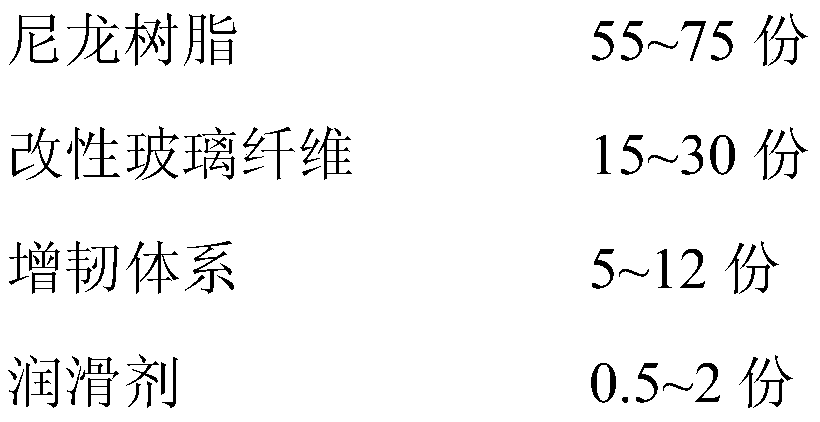

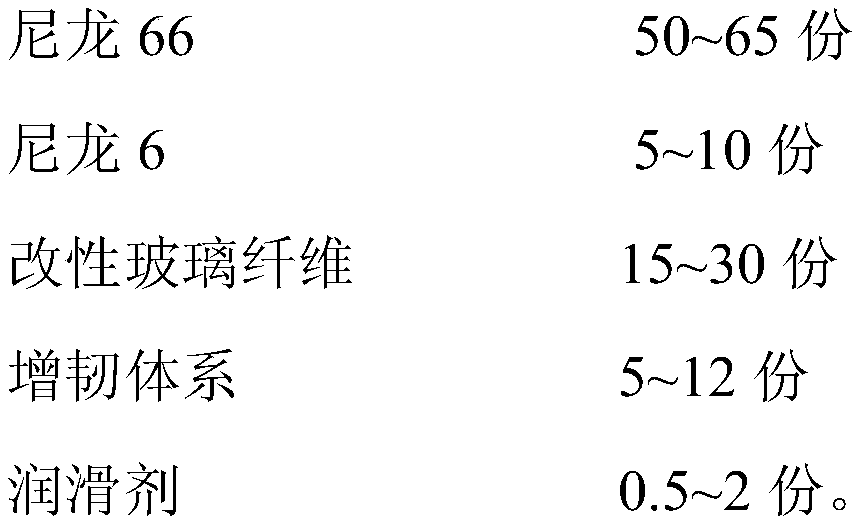

Method used

Image

Examples

Embodiment 1

[0053] Dry nylon 66 and nylon 6 resins in a vacuum oven at 90°C for 6 to 12 hours; add the silane coupling agent γ-aminopropyltriethoxysilane to the mixed solvent of ethanol / water (weight ratio 95:5) to obtain A silane coupling agent solution, soaking the glass fiber in the solution and then drying to obtain the modified glass fiber.

[0054] The dried nylon 66 and nylon 6, modified glass fiber, toughening system (amino polydimethylsiloxane: terminated epoxy dimethyl siloxane: acrylate-organic silicon copolymer toughened Agent S2001=2:2:6) and oleic acid amide are added into the high-speed mixer according to the mass ratio of 60:6:24:8:2, mixed for 3 to 5 minutes, and the obtained mixed resin is passed through the twin-screw extruder, Under the conditions of a temperature of 280°C and a screw speed of 200r / min, nylon composite materials were obtained by melt extrusion, traction, cooling and granulation.

Embodiment 2

[0056] Dry nylon 66 and nylon 6 resins in a vacuum oven at 90°C for 6 to 12 hours; add the silane coupling agent glycidyl ether propyl trimethoxysilane to the mixed solvent of ethanol / water (95:5 by weight) The silane coupling agent solution is obtained, the glass fiber is soaked in the solution and then dried to obtain the modified glass fiber.

[0057] The dried nylon 66 and nylon 6, modified glass fiber, toughening system (amino polydimethylsiloxane: terminated epoxy dimethyl siloxane: acrylate-organic silicon copolymer toughened Agent S2001=1:1:8) and erucamide were added into the high-speed mixer according to the mass parts of 65:5:20:8:2, mixed for 3 to 5 minutes, and the obtained mixed resin was passed through the twin-screw extruder, Under the conditions of a temperature of 300°C and a screw speed of 250r / min, nylon composite materials were obtained by melt extrusion, traction, cooling, and granulation.

Embodiment 3

[0059] Dry nylon 66 and nylon 6 resins in a vacuum oven at 90°C for 6 to 12 hours; add the silane coupling agent γ-aminopropyltrimethoxysilane to the mixed solvent of ethanol / water (weight ratio 95:5) to obtain A silane coupling agent solution, soaking the glass fiber in the solution and then drying to obtain the modified glass fiber.

[0060] The dried nylon 66 and nylon 6, modified glass fiber, toughening system (amino polydimethylsiloxane: terminated epoxy dimethyl siloxane: acrylate-organic silicon copolymer toughened Agent S2001=3:3:4) and stearic acid amide are added into the high-speed mixer according to the mass parts of 50:10:30:9:1, mixed for 3 to 5 minutes, and the obtained mixed resin is passed through the twin-screw extruder , under the conditions of a temperature of 260°C and a screw speed of 100r / min, the nylon composite material was obtained by melt extrusion, traction, cooling, and granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com