Super-staining-resistant waterborne coating for road fence and preparation method of super-staining-resistant waterborne coating

A water-based paint and ultra-fouling-resistant technology, used in antifouling/underwater paints, anti-corrosion paints, coatings, etc., can solve the problems of harsh drying conditions, poor film leveling, and high paint preparation costs. Enhanced self-cleaning, high water tolerance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the above-mentioned super-pollution-resistant road guardrail water-based coating, comprising the following steps:

[0048] (1) Mix 1 / 2 deionized water, 1 / 2 pH adjuster, dispersant, 1 / 2 defoamer, nano-alumina, nano-zirconia, nano-zinc oxide, silica sol, organic silicone powder , negative ion powder, and pigments were mixed, and stirred at a speed of 1000r / min for 15min;

[0049] (2) Under the condition of stirring at a speed of 500r / min, add styrene-acrylic emulsion, film-forming aids, co-solvents, 1 / 2 of the pH regulator, 1 / 2 of deionized water, and 1 / 2 of the defoamer in sequence 1. Substrate wetting agent, stirring at a speed of 1000r / min for 10min; then adding the mixture in step b, stirring at a speed of 600r / min for 10min; adding thickener in turn, stirring at a speed of 500r / min for 10min, adjusting the viscosity to pass, Instantly.

Embodiment

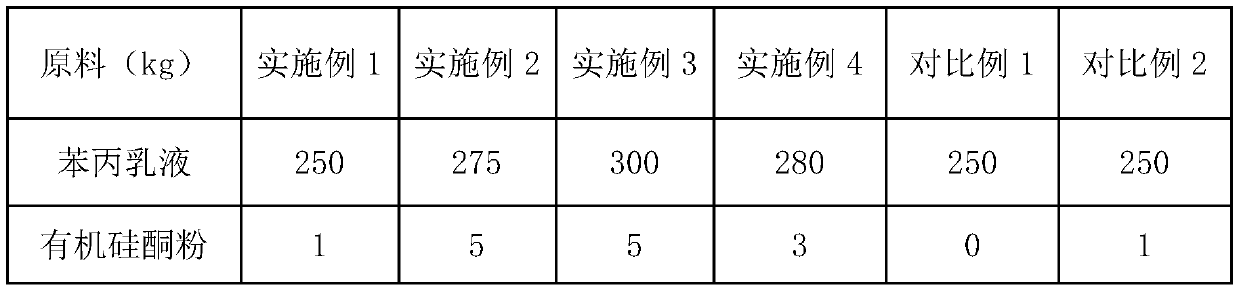

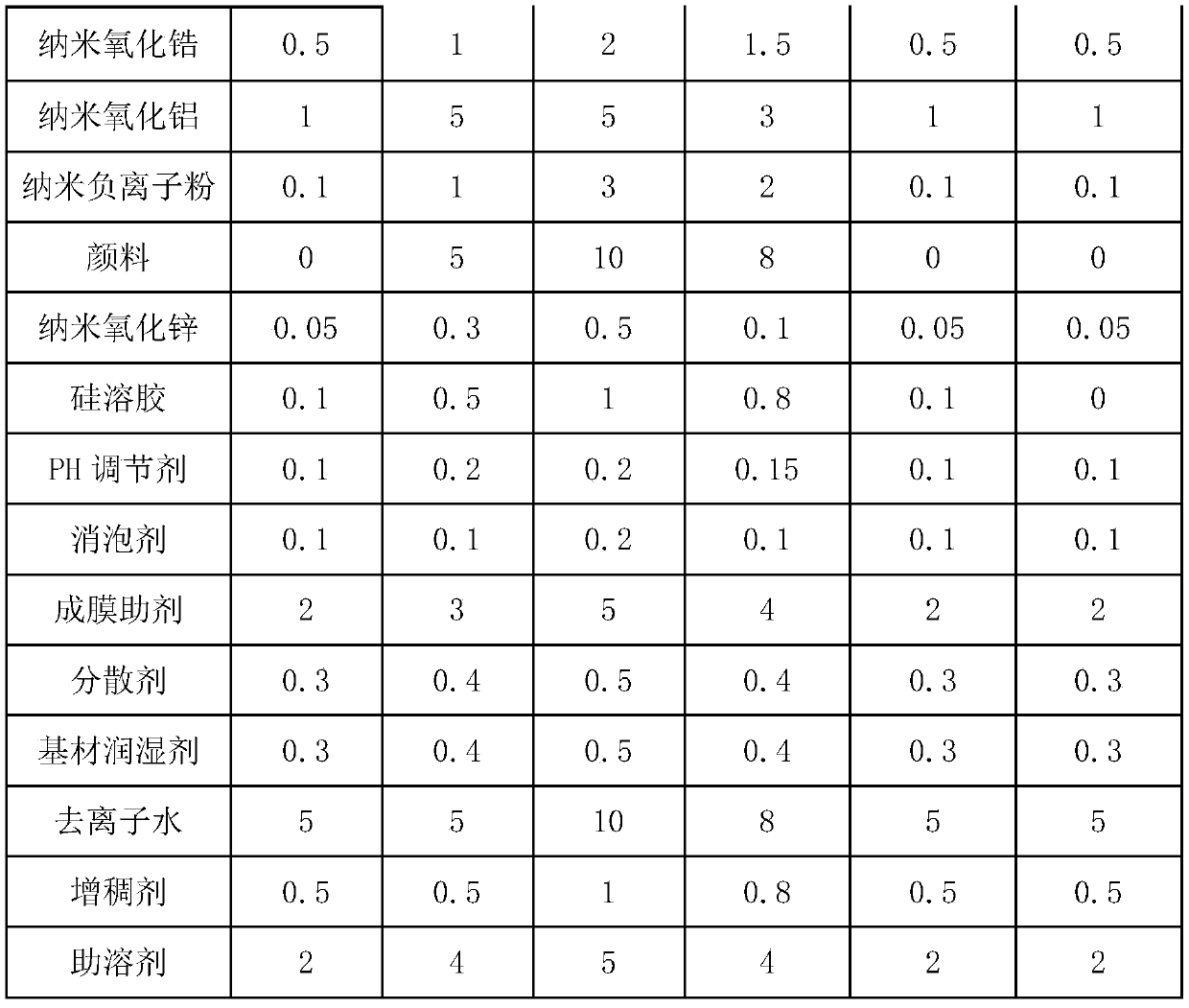

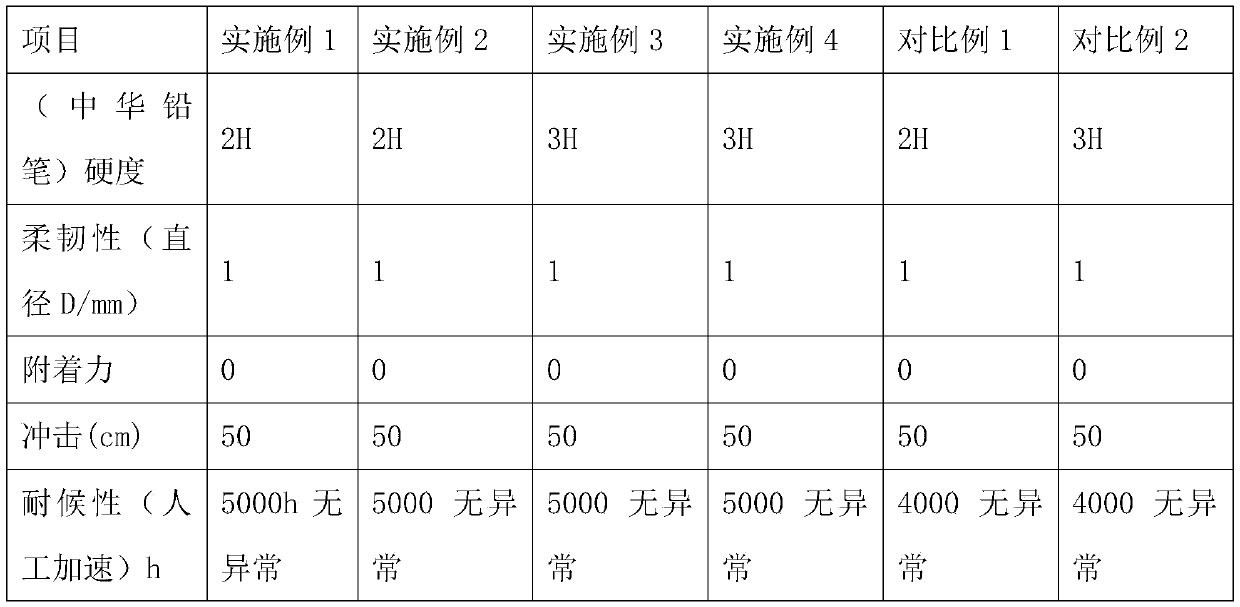

[0051] formula:

[0052] As shown in Table 1 below.

[0053] Preparation:

[0054] (1) Mix 1 / 2 deionized water, 1 / 2 pH adjuster, dispersant, 1 / 2 defoamer, nano-alumina, nano-zirconia, nano-zinc oxide, silica sol, organic silicone powder , negative ion powder, and pigments were mixed, and stirred at a speed of 1000r / min for 15min;

[0055] (2) Under the condition of stirring at a speed of 500r / min, add styrene-acrylic emulsion, film-forming aids, co-solvents, 1 / 2 of the pH regulator, 1 / 2 of deionized water, and 1 / 2 of the defoamer in sequence 1. Substrate wetting agent, stirring at a speed of 1000r / min for 10min; then adding the mixture in step b, stirring at a speed of 600r / min for 10min; adding thickener in turn, stirring at a speed of 500r / min for 10min, adjusting the viscosity to pass, Instantly.

[0056] Table 1

[0057]

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com