Preparation method and application of an anti-emulsifier for oilfield fracturing acidification

An anti-emulsifier and oilfield fracturing technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of stratum pore throat blockage, lower oil relative permeability, poor stability, etc., and achieve fluid production and Effects of increased oil production, enhanced oil recovery, and excellent interfacial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

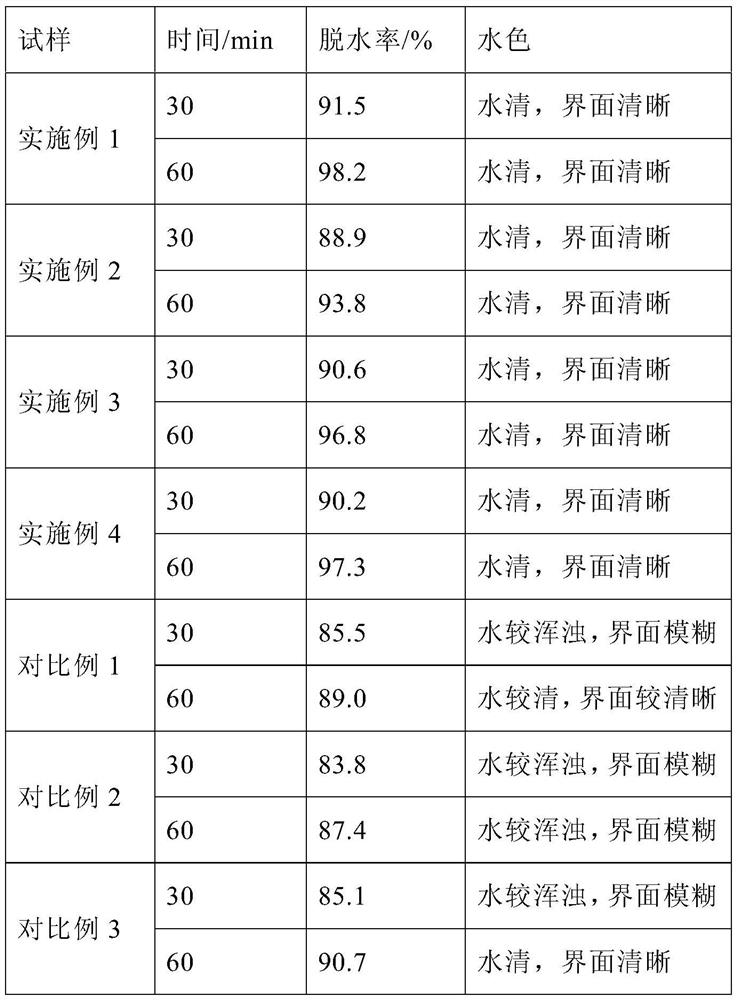

Examples

Embodiment 1

[0044] An anti-emulsifier for oil field fracturing acidification, comprising component A and component B, the mass ratio of component A and component B is 9:11;

[0045] The preparation method of this anti-emulsifying agent comprises the following steps:

[0046] S1: Preparation of Component A:

[0047] S101: Add 4kg of phenolic aldehyde resin and 2kg of potassium persulfate into a reactor with a stirring device, vacuumize, mix evenly and heat to 135°C to keep it warm.

[0048] S102: Pass 88kg ethylene oxide into the reactor and fully react, the reaction time is 25min,

[0049] S103: Add 2kg of potassium persulfate again to the reactor, mix evenly and heat, then feed 304kg of propylene oxide into the reactor and fully react, the reaction time is 25min, to obtain a dry agent;

[0050] S104: Add 600kg of ethylene glycol butyl ether after the dry agent of component A cools down to below 60°C to obtain component A with a dry agent content of 40%;

[0051] S2: Preparation of Com...

Embodiment 2

[0058] An anti-emulsifier for oil field fracturing acidification, comprising component A and component B, the mass ratio of component A and component B is 3:7;

[0059] The preparation method of this anti-emulsifying agent comprises the following steps:

[0060] S1: Preparation of Component A:

[0061] S101: Add 5kg of phenolic aldehyde resin and 2.5kg of potassium persulfate into a reactor with a stirring device, vacuumize, mix evenly and heat to 125°C to keep it warm.

[0062] S102: Pass 130g ethylene oxide into the reactor and fully react, the reaction time is 20min,

[0063] S103: Add 2.5kg potassium persulfate again to the reactor, mix evenly and heat, then pass 310kg propylene oxide into the reactor and fully react, the reaction time is 20min, to obtain dry agent;

[0064] S104: Add 550kg of ethylene glycol butyl ether after the dry agent of component A cools down to below 60°C to obtain component A with a dry agent content of 45%;

[0065] S2: Preparation of Componen...

Embodiment 3

[0072] An anti-emulsifier for oil field fracturing acidification, comprising component A and component B, the mass ratio of component A and component B is 2:3;

[0073] The preparation method of this anti-emulsifying agent comprises the following steps:

[0074] S1: Preparation of Component A:

[0075] S101: Add 9kg of phenolic aldehyde resin and 3kg of potassium persulfate into a reactor with a stirring device, vacuumize, mix evenly and heat to 130°C for heat preservation.

[0076] S102: Pass 70kg of ethylene oxide into the reactor and fully react, the reaction time is 20min,

[0077] S103: Add 3kg of potassium persulfate again to the reactor, mix evenly and heat, then feed 265kg of propylene oxide into the reactor and fully react, the reaction time is 20min, to obtain dry agent;

[0078] S104: Add 650kg of ethylene glycol butyl ether after the dry agent of component A cools down to below 60°C to obtain component A with a dry agent content of 35%;

[0079] S2: Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com