Lithium cobalt oxide composite film electrode and preparation method thereof

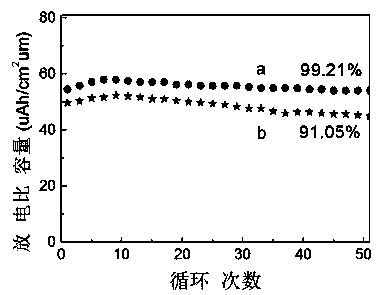

A composite film, lithium cobalt oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unfavorable electrode energy density, increase, and hinder lithium ion transportation, and achieve improved cycle stability, promote transportation, The effect of increased conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

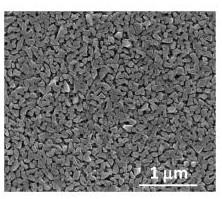

[0033] Embodiment 1: a kind of lithium cobalt oxide composite film electrode and preparation method thereof, comprises the following steps:

[0034] (1) LiCoO 2 The target and the Al target are installed in the magnetron sputtering chamber, and the vacuum is continuously pumped. The clean stainless steel substrate is placed in the substrate holder and heated to 550°C and maintained. The substrate rotation speed is 10rpm;

[0035] (2) Vacuum to the bottom vacuum 6×10 -4 After Pa, after passing Ar gas, the sputtering pressure is 2.5Pa, and the co-sputtering of LiCoO 2 target and Al target, of which LiCoO 2Target parameters are: target base distance 5cm, sputtering power 160W, Al target parameters are: target base distance 6.5cm, sputtering power 20W;

[0036] (3) Cool naturally after sputtering to obtain a lithium cobalt oxide composite thin film electrode.

Embodiment 2

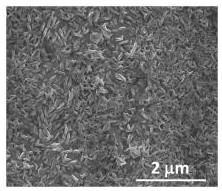

[0037] Embodiment 2: a kind of lithium cobalt oxide composite film electrode and preparation method thereof, comprises the following steps:

[0038] (1) LiCoO 2 The target and the Al target are installed in the magnetron sputtering chamber, and the vacuum is continuously pumped. The clean stainless steel substrate is placed in the substrate holder and heated to 550°C and maintained. The substrate rotation speed is 10rpm;

[0039] (2) Vacuum to the bottom vacuum 6×10 -4 After Pa, a mixed gas of argon and oxygen is introduced, wherein the volume ratio of argon and oxygen is 4:1, so that the sputtering pressure is adjusted to 2.5Pa, and the co-sputtering of LiCoO 2 target and Al target, of which LiCoO 2 Target parameters are: target base distance 5cm, sputtering power 160W, Al target parameters are: target base distance 6.5cm, sputtering power 20W;

[0040] (3) Cool naturally after sputtering to obtain a lithium cobalt oxide composite thin film electrode.

Embodiment 3

[0041] Embodiment 3: a kind of lithium cobalt oxide composite film electrode and preparation method thereof, comprises the following steps:

[0042] (1) LiCoO 2 The target and the Al target are installed in the magnetron sputtering chamber, and the vacuum is continuously pumped. The clean stainless steel substrate is placed in the substrate holder and heated to 500°C and maintained. The substrate rotation speed is 10rpm;

[0043] (2) Vacuum to the bottom vacuum of 7×10 -4 After Pa, after passing Ar gas, the sputtering pressure is 2.5Pa, and the co-sputtering of LiCoO 2 target and Al target, of which LiCoO 2 Target parameters are: target base distance 6cm, sputtering power 200W, Al target parameters are: target base distance 7cm, sputtering power 30W;

[0044] (3) Cool naturally after sputtering to obtain a lithium cobalt oxide composite thin film electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com