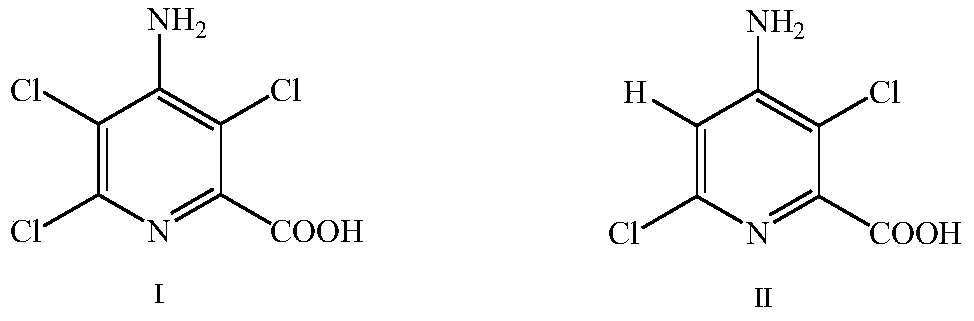

Method for preparing 4-amino-3,6-dichloropicolinic acid by electrochemical selective dechlorination

A diclopyralid and selectivity technology, applied in electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of silver electrode dechlorination activity and selectivity that are difficult to guarantee and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of activated silver electrode

[0023] (1) Soaking: Soak the silver net (purity is 99.99wt%, size is 0.3cm * 4.0cm * 6.0cm) in static 10wt% hydrochloric acid aqueous solution (prepared with deionized water), 20 ℃ for 20min, after soaking silver network;

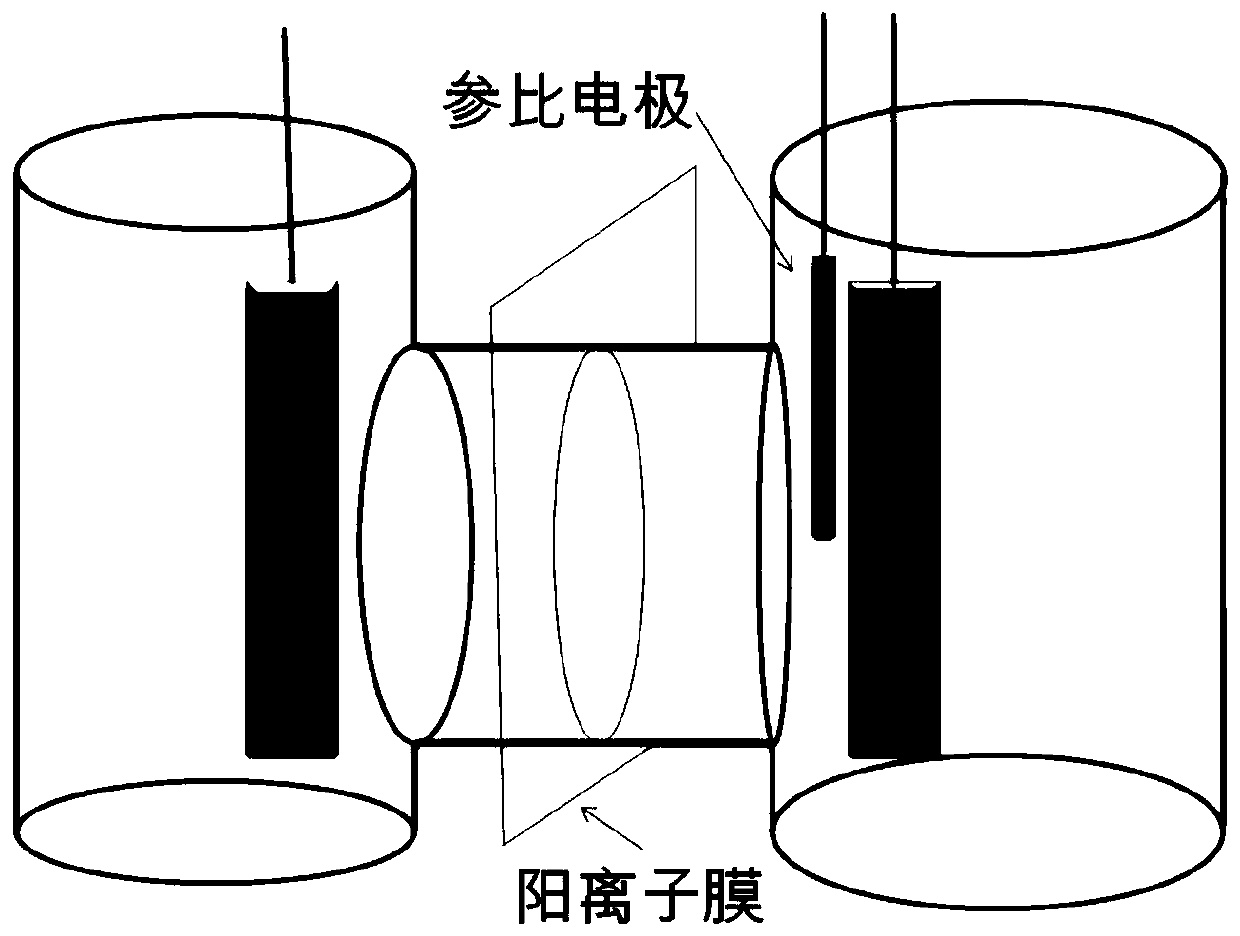

[0024] (2) Oxidation: in H-type electrolyzer with Nafion 117 cation membrane as diaphragm (such as figure 1 Shown), in step (1) the silver mesh is the working electrode, and the platinum sheet of the same area is the counter electrode; silver / silver chloride is the reference electrode. The working electrode chamber is 0.1M NaCl+1.0M NaOH aqueous solution (prepared with deionized water), and the counter electrode chamber is 1.0M sodium hydroxide aqueous solution (prepared with deionized water). Control the temperature of the aqueous solution in the working electrode chamber to 20-25°C, first apply 0.5A / dm to the silver electrode 2 The anodizing current until the electrode potential reach...

Embodiment 2

[0026] Embodiment 2: the preparation of activated silver electrode

[0027] (1) Soaking: the silver nets with a purity of 99.95wt% (recorded as silver mesh 1#) and 99.0wt% (recorded as silver mesh 2#) and a size of 0.3cm×4.0cm×6.0cm were soaked respectively In 15wt% hydrochloric acid aqueous solution (prepared with deionized water), stand at 25°C for 60min;

[0028] (2) Oxidation: In an H-type electrolytic cell with Nafion 117 cationic membrane as a diaphragm ( figure 1 ), respectively with step (1) silver mesh 1# and silver mesh 2# as the working electrode, the platinum sheet of the same area as the counter electrode; silver / silver chloride as the reference electrode. The working electrode chamber is 1.0M NaCl aqueous solution (prepared with deionized water), and the counter electrode chamber is 1.0M sodium hydroxide aqueous solution (prepared with deionized water). Control the temperature of the aqueous solution in the working electrode chamber to 20-25°C, first apply 2A / d...

Embodiment 3

[0030] Embodiment 3: the preparation of activated silver electrode (hydrochloric acid does not soak)

[0031] (1) Oxidation: In the H-type electrolytic cell with Nafion 117 cationic membrane as the diaphragm ( figure 1), the silver mesh (purity is 99.95wt%, size is 0.3cm * 4.0cm * 6.0cm) is the working electrode; the platinum sheet of the same area is the counter electrode; silver / silver chloride is the reference electrode. The working electrode chamber is 0.1M NaCl+1.0M NaOH aqueous solution (prepared with deionized water), and the counter electrode chamber is 1.0M sodium hydroxide aqueous solution (prepared with deionized water). Control the temperature of the aqueous solution in the working electrode chamber to 20-25°C, first apply 0.5A / dm to the silver grid 2 The anodizing current until the electrode potential reaches +0.5vs.vs.Ag / AgCl;

[0032] (2) Reduction: use the silver mesh in step (1) as the counter electrode, the platinum sheet as the working electrode, and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com