Probe type refractive index sensor based on surface plasma resonance

A refractive index sensor and surface plasmon technology, applied in the field of optical fiber sensing, can solve the problems of high manufacturing process difficulty and low sensitivity, and achieve the effects of improving sensitivity and reducing the diameter of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

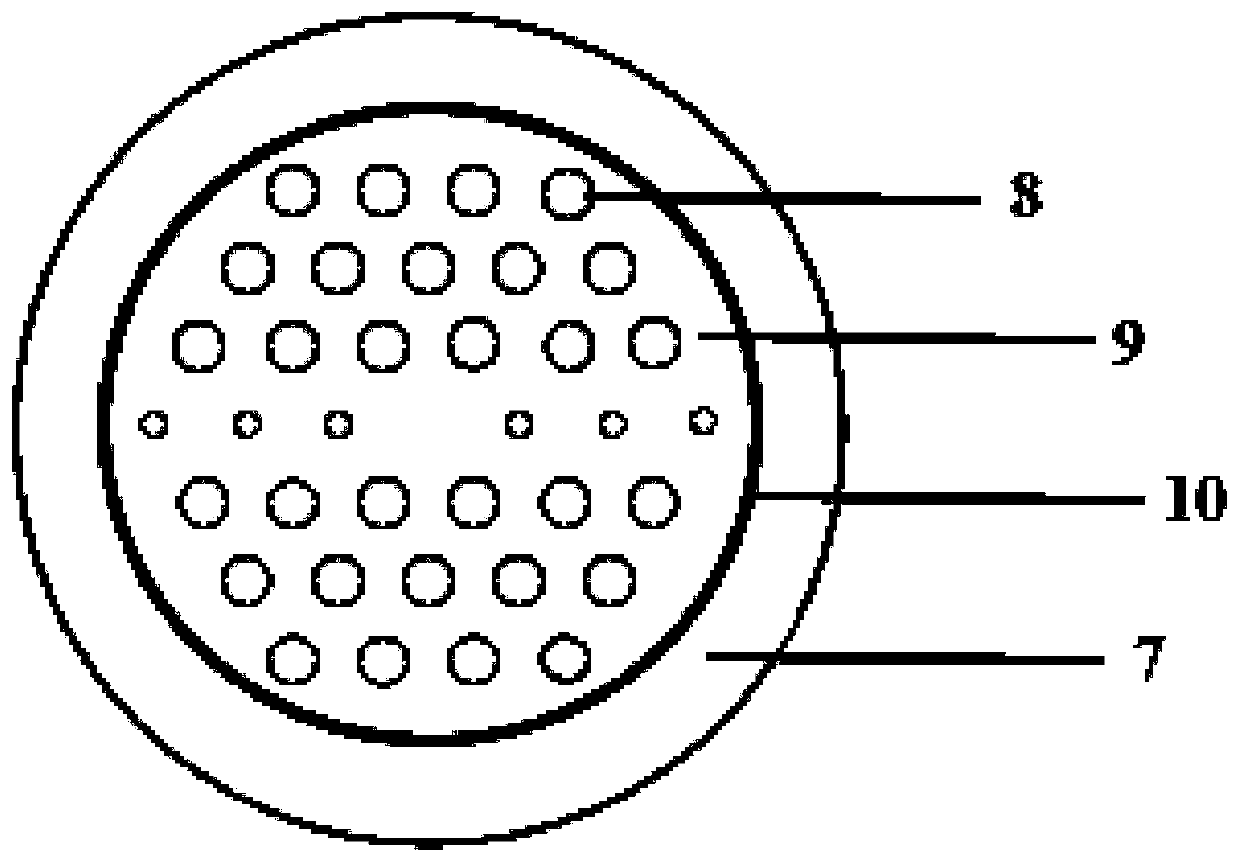

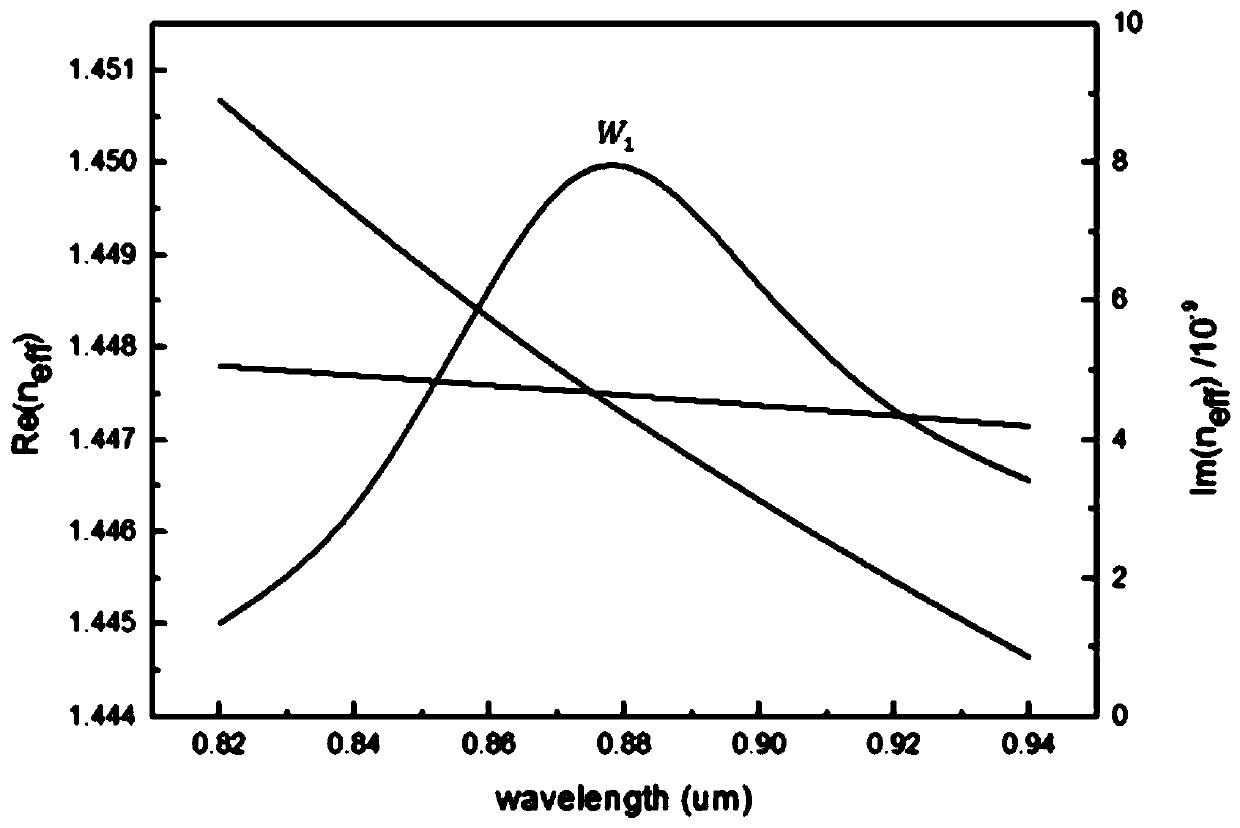

[0031] Use COMSOL Multiphysics simulation software to establish a photonic crystal fiber geometric model and perform numerical simulation and mode analysis, and record the effective refractive index n of the core mode and surface plasmon mode at different wavelengths eff , the effective refractive index curves of the two and the imaginary part of the core mode Im(n eff ) Characterized by the loss characteristic diagram as shown in image 3 As shown, the refractive index to be measured is set to 1.413 at this time, and a resonant loss peak W is generated in the output spectrum 1 .

example 2

[0033] Change the refractive index of the sample to be measured, using image 3 According to the judgment method shown, the loss curve of the core mode of the fiber under different refractive indices is obtained, and the peak wavelength is read. After simulation calculation, a series of corresponding resonance wavelength data under different refractive indices are obtained. According to the obtained data, the wavelength-refractive index curve can be drawn by using Origin drawing software. The present invention can realize the refractive index transmission in the range of 1.39-1.42. sense, after data fitting, the curve is as Figure 4shown. It can be seen from the figure that the resonance wavelength is proportional to the increase of the refractive index of the liquid to be measured. According to the sensitivity calculation formula, S=θλ / θn, the sensitivity of the refractive index sensing structure can be calculated to be 10315nm / RIU. When actually measuring the refractive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com