Nano composite material, preparation method thereof and application in HIFU synergist

A technology of nanocomposite materials and synergists, applied in the field of nanomaterials and HIFU, can solve the problems of inability to effectively solve the problem of complete ablation of deep lesions, inability to completely ablate tumor recurrence and metastasis, inability to accurately identify tumor tissue boundaries, etc., and achieve internal circulation Short time, long circulation time in the body, and the effect of increasing the active oxygen level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Example 1 Black TiO 2 Nanoparticle preparation

[0094] Black TiO 2 Nanoparticle preparation

[0095] Take nano TiO 2 20mg of powder, placed in a high-pressure hydrogen system, pressure 22.0bar, temperature 450℃, hydrogenation for 5 days, after the reaction is over, black TiO is obtained 2 Nanoparticles.

[0096] Black ZrO 2 Nanoparticle preparation

[0097] Take Nano ZrO 2 30mg of powder, placed in a high pressure hydrogen system, pressure 20.0bar, temperature 350℃, hydrogenation for 5 days, after the reaction is over, black ZrO is obtained 2 Nanoparticles.

[0098] Preparation of black ZnO nanoparticles

[0099] Take 30 mg of nano-ZnO powder and place it in a high-pressure hydrogen system at a pressure of 20.0 bar, a temperature of 350° C., and hydrogenation for 5 days. After the reaction, black ZnO nanoparticles are obtained.

Embodiment 2

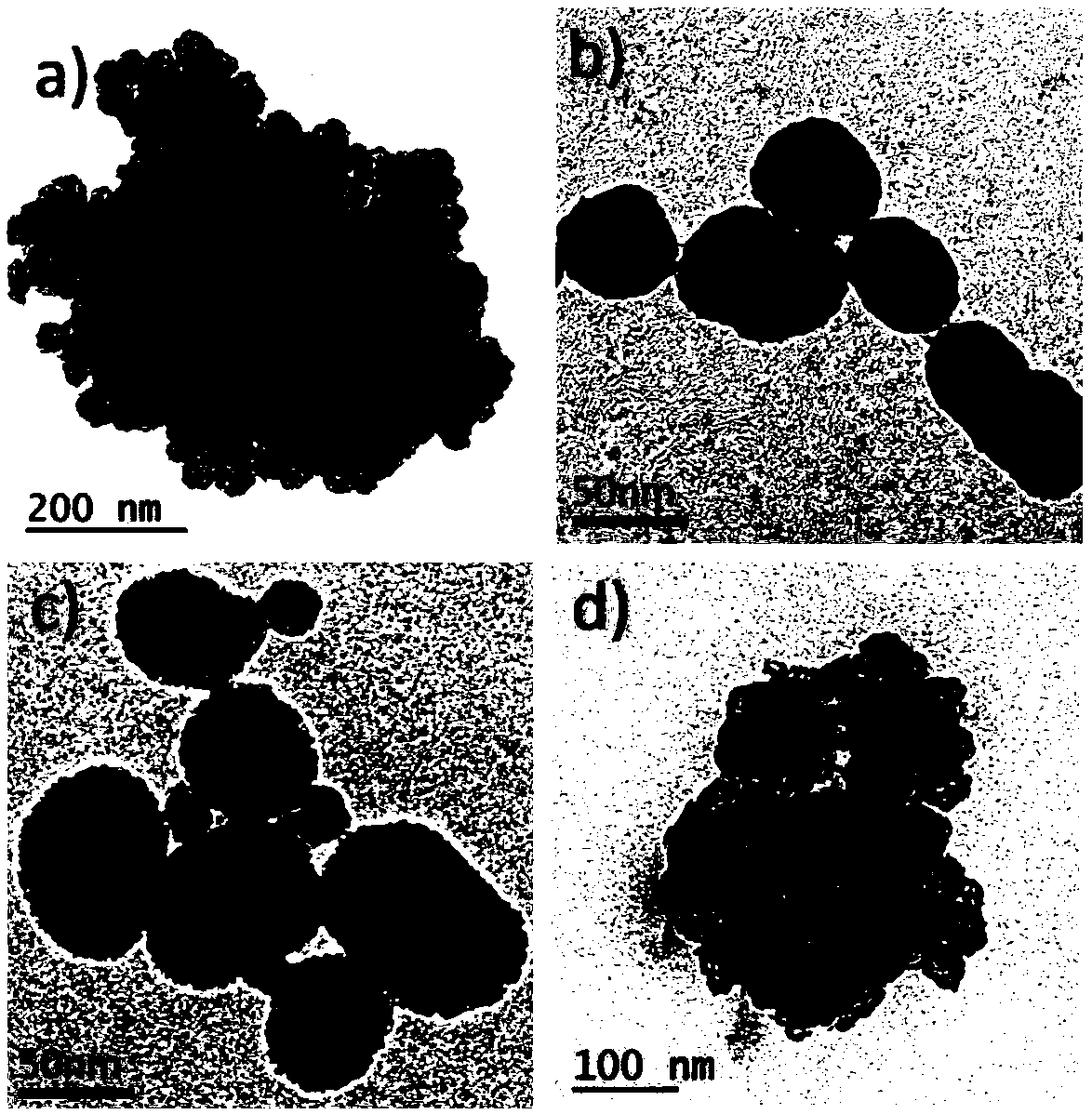

[0100] Example 2 Preparation of hollow mesoporous black nanoparticles

[0101] Hollow mesoporous black TiO 2 Nanoparticle preparation

[0102] Reference (Angew.Chem.Int.Ed.2014,53,12590-12593.) method, using a hydrothermal method to prepare carbon spheres with a particle size of 50nm. Take 40mg of carbon balls and disperse in 100mL of absolute ethanol. Take 1mL of tetrabutyl titanate and add it dropwise to the above-mentioned absolute ethanol. After stirring well, take 0.5mL of ammonia water and add it to the above-mentioned absolute ethanol dropwise, react at 40℃ 18 hours. After the reaction, centrifuge for 30 minutes at a speed of 12000 rpm to remove the supernatant, collect the precipitate, dry it at 100°C, transfer it to a tube furnace, and calcinate at 500°C for 2 hours to obtain a hollow medium Porous TiO 2 Nanoparticles. Take hollow mesoporous TiO 2 40mg of nano-particle powder, placed in a high-pressure hydrogen system, pressure 22.0bar, temperature 450℃, hydrogenation ...

Embodiment 3

[0105] Example 3 Preparation of PEG-modified hollow mesoporous black nanoparticles

[0106] PEG modified hollow mesoporous black TiO 2 Nanoparticle preparation

[0107] PEG modified hollow mesoporous black TiO 2 Nanoparticles: Take the hollow mesoporous black TiO prepared in Example 2 2 20 mg of nanoparticles were dispersed in 100 mL of absolute ethanol, 100 mg of PEG (molecular weight 2000) was added, and stirred for 8 hours. The solution was collected, centrifuged at 10,000 rpm for 20 minutes, the supernatant was removed, washed with deionized water, and centrifuged twice. Obtain PEG-modified hollow mesoporous black TiO 2 Nanoparticles.

[0108] PEG modified hollow mesoporous black ZrO 2 Preparation of Nanoparticles and PEG-modified Hollow Mesoporous Black ZnO Nanoparticles

[0109] PEG modified hollow mesoporous black ZrO 2 Preparation of Nanoparticles and PEG-modified Hollow Mesoporous Black ZnO Nanoparticles and PEG-modified Hollow Mesoporous Black TiO 2 The preparation proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com