Small methanol hydrogen production apparatus for driving hydrogen engine

A technology for hydrogen production and engine from methanol, applied in the fields of hydrogen/syngas production, hydrogen, inorganic chemistry, etc., can solve the problems of uneven heating area of heat transfer oil, large equipment as a whole, short service life, etc., to reduce steel consumption, The effect of large heating area and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

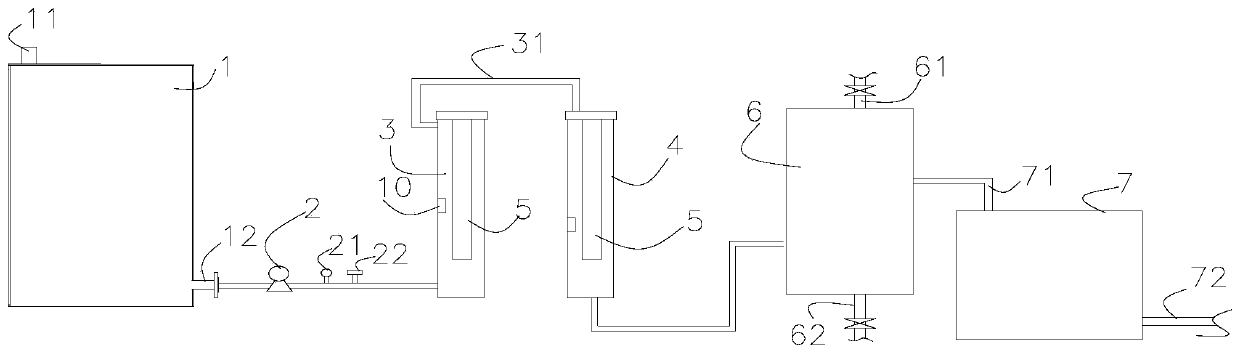

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

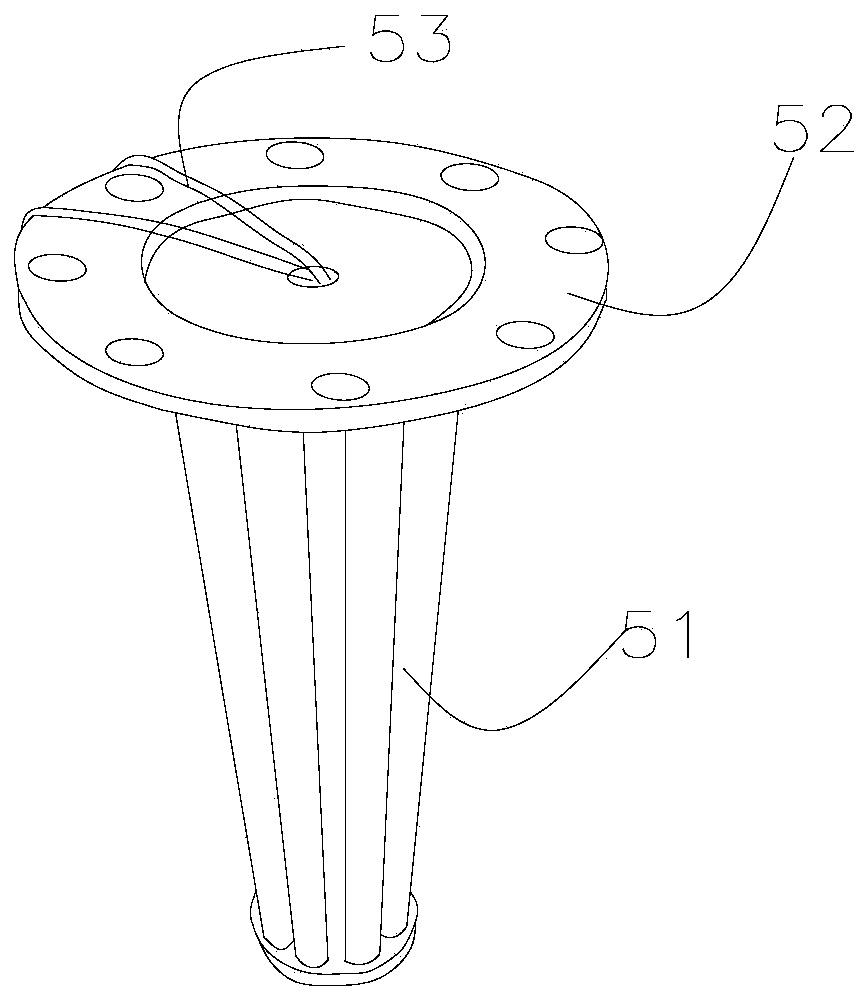

[0028] A small methanol hydrogen production device driven by a hydrogen engine of the present invention comprises an alcohol-water storage tank 1, an electromagnetic metering pump 2, a vaporization tube 3, a cracking tube 4, an electromagnetic induction heating rod 5, and a hydrogen storage buffer tank 6;

[0029] The alcohol-water storage tank 1 is used to store methanol and aqueous solution for hydrogen production, wherein the volume ratio of methanol to water is 50% of methanol and 50% of water. The side of the alcohol-water storage tank 1 is provided with a mixed liquid inlet valve 11, and the bottom end is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com