Coextraction method for phaeodactylum tricornutum fucoxanthine and polyunsaturated fatty acid

A technology for unsaturated fatty acids and Phaeodactylum fucoidans, which is applied in the field of bioengineering, can solve the problems of different physical and chemical properties, inapplicability, etc., and achieves the effects of easy recovery, cost control, and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for co-extracting Phaeodactylum tricornutum fucoxanthin and polyunsaturated fatty acids, comprising the steps of:

[0059] 1. Take a small amount of the harvested algae mud and weigh it. After calculating the weight, put the wet algae mud into an oven at 105°C for 12 hours. After drying, calculate the weight after drying. Calculate the water content of the wet algae mud according to the weight difference before and after.

[0060] 2. When the water content of the wet algae mud does not exceed 85%, add absolute ethanol to the wet algae mud. The mass volume ratio of the wet algae mud to absolute ethanol is 1:3, and the unit is g / ml.

[0061] 3. Stir the mixed solution at 45°C with an automatic stirrer, and keep away from light during the whole process.

[0062] 4. After stirring and extracting for 3 hours, use a suction filtration device to separate the solid algae residue from the extract, and use a polypropylene filter membrane with a pore size of 10 μm for su...

Embodiment 2

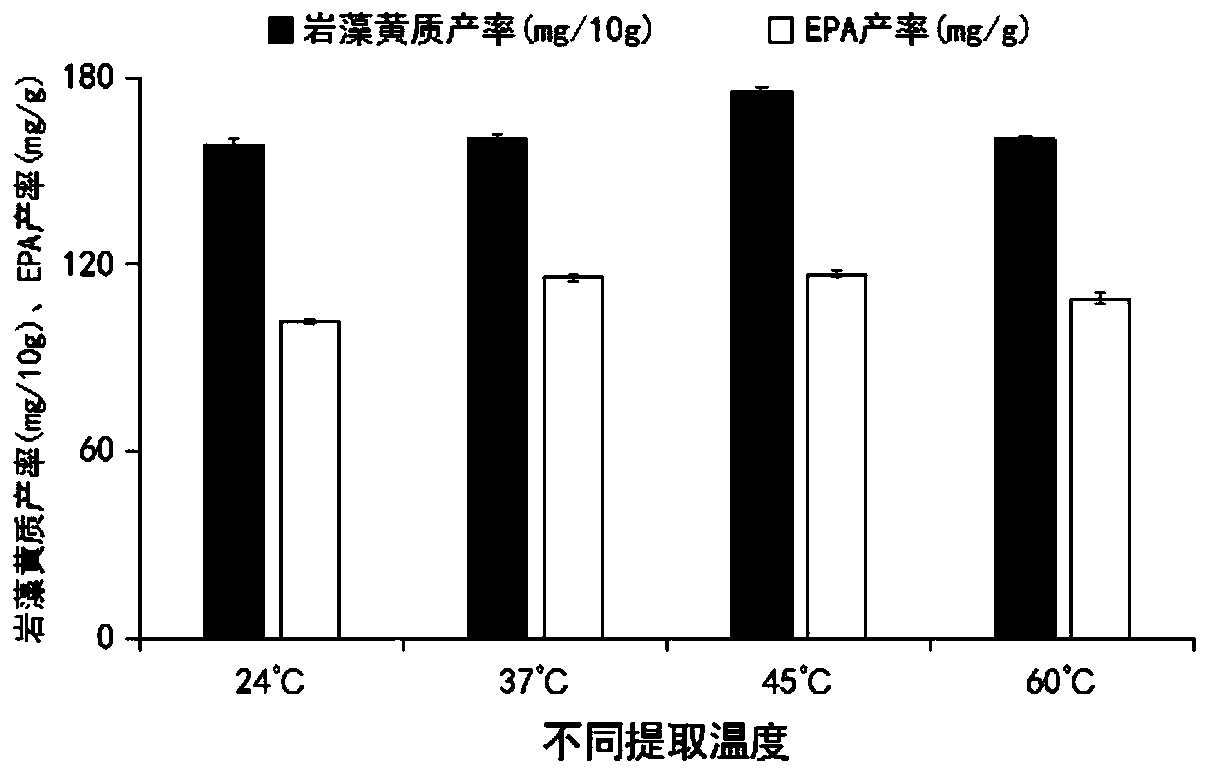

[0074] Example 2 is basically the same as Example 1, except that the extraction temperatures used in step 3 and step 6 are 24°C, 37°C, 45°C and 60°C, respectively.

[0075] It has been tested that the extraction rate of fucoxanthin is different at different temperatures, and the extraction efficiency is the highest at 45°C. The extraction efficiency of EPA is also different at different temperatures, and the extraction efficiency of EPA is the highest at 37°C and 45°C. Based on the above, 45°C is the optimal temperature for extraction ( image 3 ).

Embodiment 3

[0077] Embodiment 3 is basically the same as Example 1, the difference being that the ratio of ethanol and normal hexane used in step 5 is different, when the quality of algae cake 1 obtained in step 5 is 1, use different volume ratios of ethanol and normal hexane to carry out Extraction is respectively ethanol:n-hexane=1:3; ethanol:n-hexane=1:2; ethanol:n-hexane=1:1; ethanol:n-hexane=1:0.5.

[0078] After testing, different solvent ratios will also affect the extraction efficiency, mainly affecting the extraction of oil. Under the condition of ethanol:n-hexane=1:2 or 1:3, the extraction efficiency of oil is the highest, based on economical efficiency Considering, use ethanol: the condition of normal hexane=1:2 as optimal oil extraction condition ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com