Preparation method of wear-resistant self-cleaning plastic shoe cover material

A self-cleaning, plastic technology, applied in the field of plastic processing, can solve the problems of plastic shoe covers not wearing, affecting the use effect, unable to solve the problem of overshoes, etc., to achieve the effect of improving aging resistance, easy cleaning and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

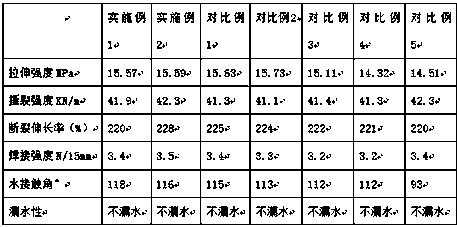

Examples

Embodiment 1

[0019] The method for preparing wear-resistant and self-cleaning plastic shoe cover material specifically includes the following steps:

[0020] (1) Put the polyol mixture and catalyst into the reaction kettle, raise the temperature to 180°C, draw a vacuum while heating up, control the pressure in the reaction kettle to -0.1MPa and the temperature to 180°C for dehydration for 2h, then cool to 105°C and pass in Release the vacuum with nitrogen to obtain mixture A; heat the thiophosphoric acid tris(4-phenylisocyanate), cyclohexanedimethylene diisocyanate, and chain extender to 80°C and mix them with mixture A uniformly, and then pass the host speed 300r / min, melt pressure 0.2MPa, compression zone temperature 170°C, melting zone 175°C, metering zone 175°C twin-screw extruder reacts and extrudes to obtain polyurethane elastomer; the catalyst accounts for the total polyol mixture 0.5% by mass; the mass ratio of the thiophosphoric acid tris (4-phenyl isocyanate), cyclohexane dimethylen...

Embodiment 2

[0028] A preparation method of wear-resistant self-cleaning plastic shoe cover material specifically includes the following steps:

[0029] (1) Put the polyol mixture and catalyst into the reaction kettle, raise the temperature to 180°C, draw a vacuum while heating, control the pressure in the reaction kettle to -0.08MPa and the temperature to 160°C for dehydration for 0.5h, then cool to 95°C, pass Enter nitrogen to release the vacuum to obtain mixture A; heat the thiophosphoric acid tris(4-phenylisocyanate), cyclohexanedimethylene diisocyanate, and chain extender to 50°C and mix with mixture A uniformly, and then pass through the host A twin-screw extruder with a speed of 300r / min, a melt pressure of 0.2MPa, a compression section temperature of 175°C, a melting section of 180°C, and a metering section of 185°C reacted and extruded to obtain a polyurethane elastomer; the catalyst accounts for the proportion of the polyol mixture 0.01% of the total mass; the mass ratio of said thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com