Novel method for fermentation production of erythrocin by utilizing saccharopolyspora erythraea

A technology of erythromycin and fermentation liquid, applied in the field of bioengineering, can solve the problems of low industrial application value, unfavorable erythromycin research, low erythromycin yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1, fermentation culture

[0070] In this example, a 5L fermenter was used for fermentation, and the optimized synthetic medium of the present invention was used as the fermentation medium.

[0071] 1. Cleaning, inoculation and cultivation

[0072] Before inoculation, the strains were washed. For the rapid germination of spores and the growth of hyphae, the seed medium is a compound medium, and the bacteria are cleaned with physiological saline. First, after sterilizing the normal saline, empty 500mL shaker flasks and enough empty 50mL centrifuge tubes, put them into the ultra-clean workbench. Wipe the seed shake flask cultivated for 48 hours with alcohol cotton, and put it into the ultra-clean workbench. Then, pour the culture medium in the seed shake flask into an empty centrifuge tube, close the lid tightly, and centrifuge at 3000rpm for 10min. After taking out the centrifuge tube, wipe the tube wall with alcohol cotton, put it into the ultra-clean work...

Embodiment 2

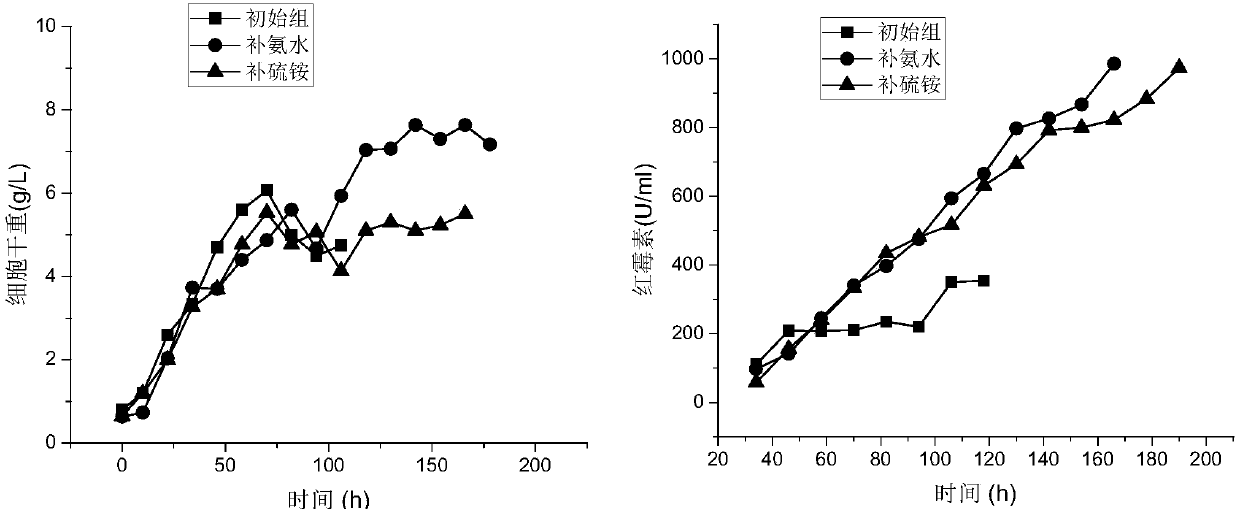

[0117] Embodiment 2, the research of erythromycin yield and cell dry weight in fermentation process

[0118] Use 0.5L shake flasks as seed shake flasks, the initial group is to apply the original medium (M1); the strategy of the strategy group for supplementing ammonia water is to reduce the total amount of amino acids in the original medium by 20% (M2), and add ammonia water in the process. Nitrogen source: Ammonium sulfate supplementation strategy The strategy of the group is to use medium M2 and supplement ammonium sulfate as a nitrogen source during the process.

[0119] See figure 1 In the left picture, in terms of dry cell weight, due to the high amino acid content in the basal medium of the initial group, the dry cell weight at 30-60h is higher. However, the inventors also noticed that although the dry weight of the cells increased rapidly, the bacterial cells autolyzed rapidly after the nitrogen source was consumed. That is to say, there is a rapid decrease in dry ce...

Embodiment 3

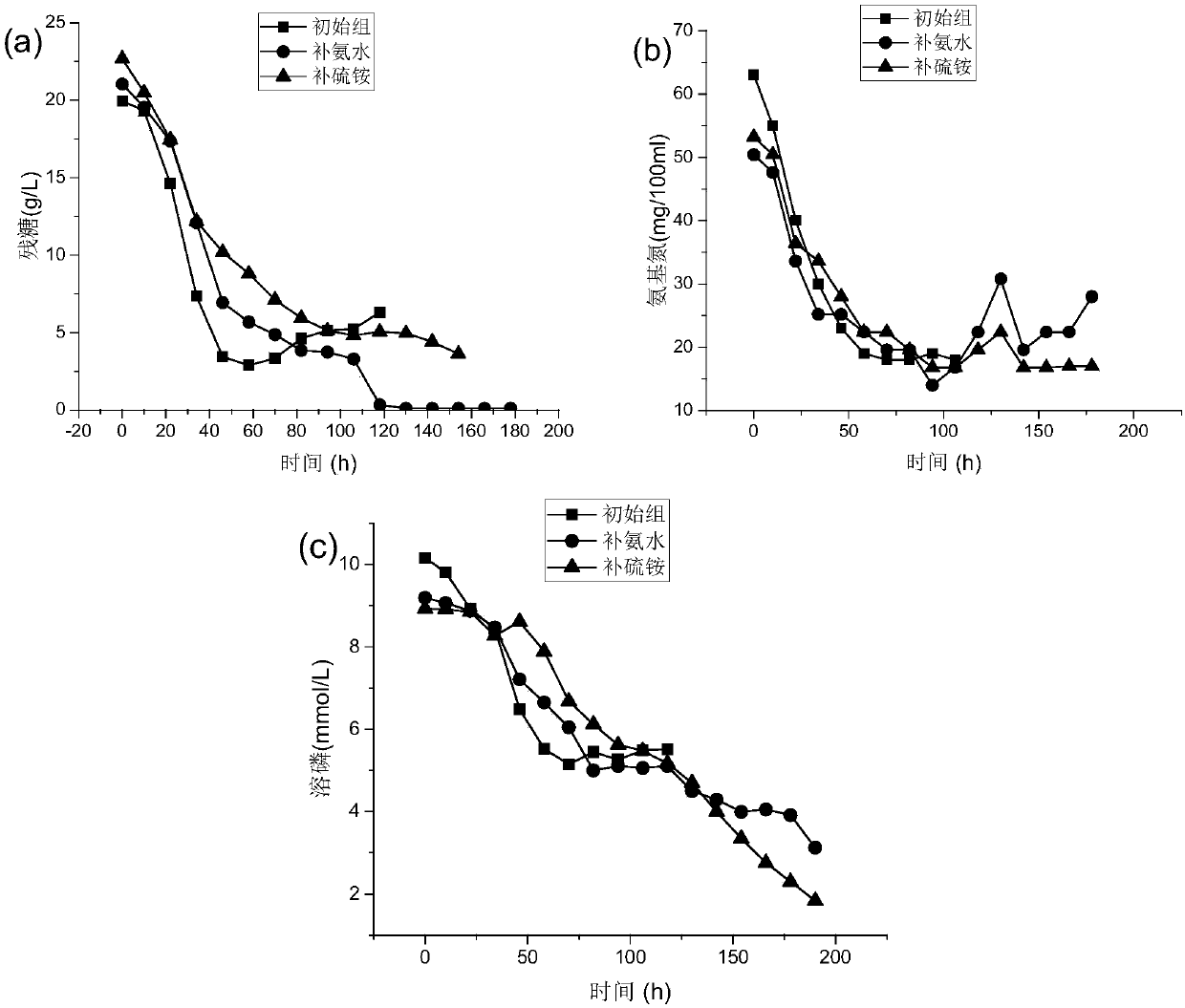

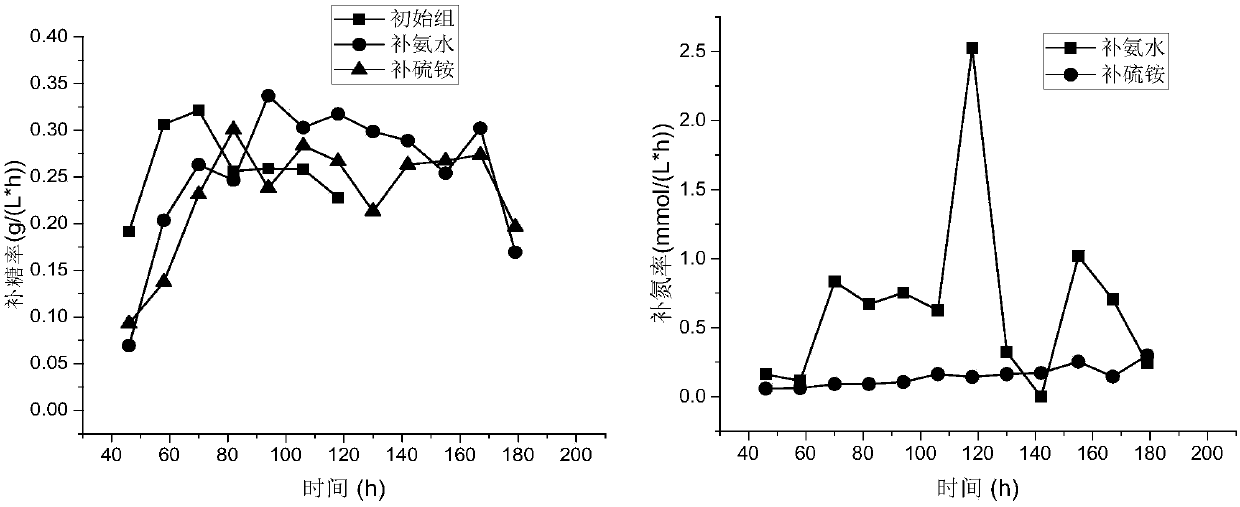

[0121] Embodiment 3, the utilization of glucose, phosphorus, nitrogen source in fermentation process

[0122] Glucose is utilized during fermentation as figure 2 (a), from the perspective of residual sugar in the first 40 hours, the sugar consumption rate of the initial group was the fastest, and the sugar consumption rate of the ammonia supplementation strategy group and the ammonium sulfate supplementation strategy group were basically the same, but after 40 hours, the residual sugar of the ammonium sulfate supplementation strategy group The overall value was higher than that of the ammonia supplementation strategy group, which may be related to the lower supplementation of ammonium sulfate. The residual sugar in the ammonia water supplementation strategy group was zero at 118 hours due to more ammonia water supplementation and glucose depletion.

[0123] The utilization of amino nitrogen in the fermentation process is as follows: figure 2 (b), before 100h, the change tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com