Sealing method of differential strain method ground stress test element

A technology for testing pieces and in-situ stress, which is applied in natural gas geology, exploration and development projects, and petroleum fields. It can solve problems such as inability to ensure uniform sealant, influence of sealant on rock sample components, and complicated methods, and achieve heat curing and water resistance. Strong performance and simple encapsulation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The method for sealing the stress test piece of the differential strain method comprises the following steps:

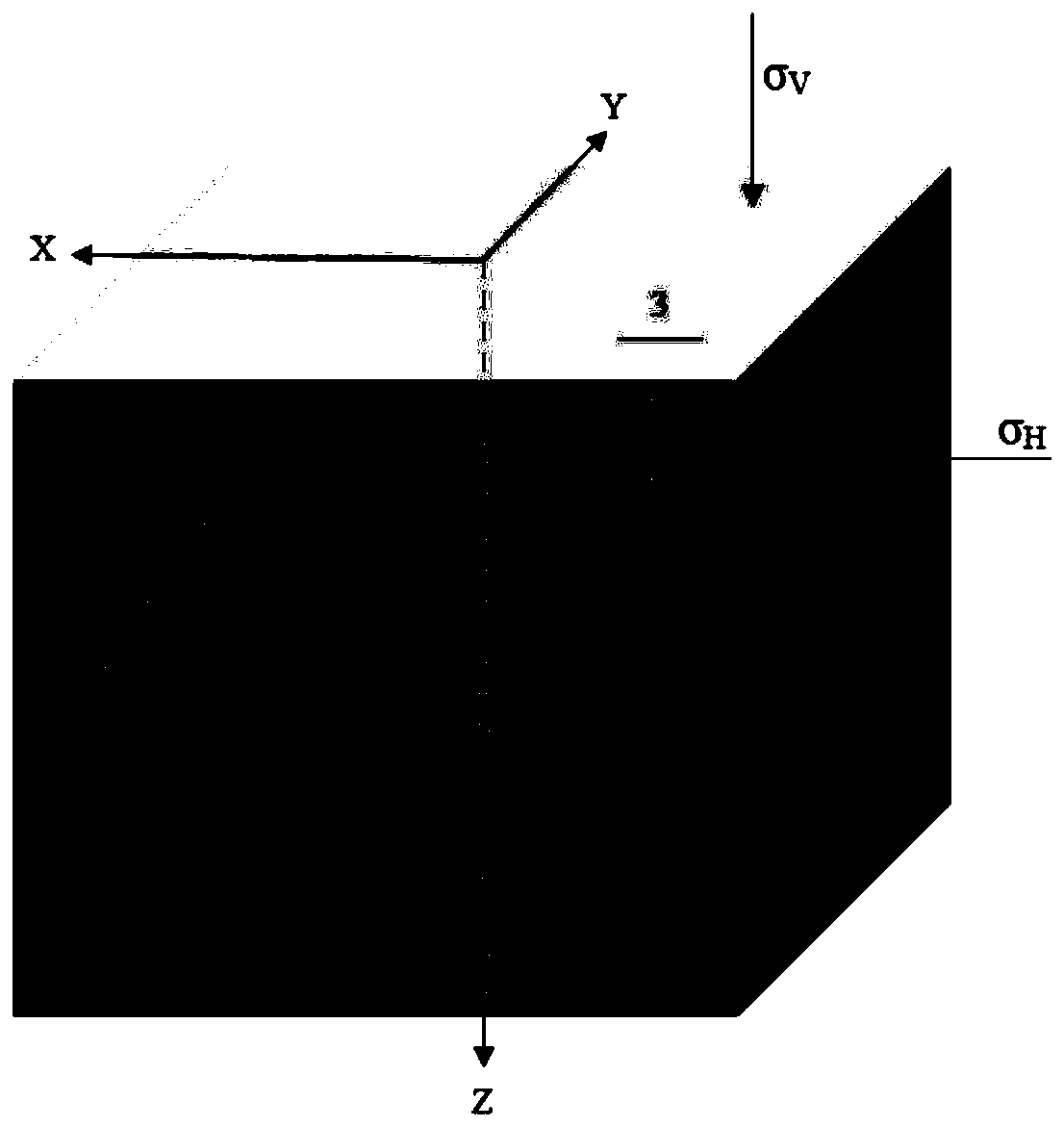

[0057] Make rock samples according to the requirements, polish the surface of the rock samples smoothly, then dry them in an oven, wipe the surface of the rock samples with anhydrous ethanol, wipe the rock samples clean, and paste the strain gauges on the corresponding positions of the test pieces. The location of the slice is as follows figure 1 shown;

[0058] Make sealing molds, sealing molds such as image 3 As shown, the inner groove of the sealing mold matches the shape of the rock sample, and the size of the inner groove is slightly larger than the rock sample for the rock sample to be put in. The sealing mold is made of metal, and its size is 4.1cm*5.4cm*6.5cm; Apply a lubricant to the inner surface of the sealed mold, the lubricant is preferably lubricating silicone grease;

[0059] Preparation of sealant: Weigh 6101 bisphenol A epoxy resin, methyl...

Embodiment 2

[0065] The method for sealing the stress test piece of the differential strain method comprises the following steps:

[0066] Make rock samples according to the requirements, polish the surface of the rock samples smoothly, then put them in an oven to dry, wipe the surface of the rock samples with acetone, wipe the rock samples clean, and paste the strain gauges on the corresponding positions of the test pieces;

[0067] Make a sealing mold, open an inner groove on the metal sealing mold, the inner groove matches the shape of the rock sample, and the size of the inner groove is slightly larger than the rock sample for the rock sample to be put in; the size of the sealing mold is 4.1cm*5.4cm* 6.5cm; and apply lubricating silicone grease on the surface forming the inner groove;

[0068] Preparation of sealant: Weigh 6101 bisphenol A epoxy resin, methyl tetrahydrophthalic anhydride, dibutyl phthalate, activated nano-alumina and polyurethane and pour them into paper cups, the rati...

Embodiment 3

[0073] The method for sealing the stress test piece of the differential strain method comprises the following steps:

[0074] Make rock samples according to the requirements, polish the surface of the rock samples smoothly, then put them in an oven to dry, wipe the surface of the rock samples with acetone, wipe the rock samples clean, and paste the strain gauges on the corresponding positions of the test pieces;

[0075] Make a sealing mold, open an inner groove on the metal sealing mold, the inner groove matches the shape of the rock sample, and the size of the inner groove is slightly larger than the rock sample for the rock sample to be put in; the size of the sealing mold is 4.1cm*5.4cm* 6.5cm; and apply lubricating silicone grease on the surface forming the inner groove;

[0076] Preparation of sealant: Weigh 6101 bisphenol A epoxy resin, methyl tetrahydrophthalic anhydride, dibutyl phthalate, active nano silicon oxide and polyurethane and pour them into a paper cup, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com