Mn-doped lithium ferrate, lithium supplement positive electrode material and preparation and application thereof

A technology of lithium ferrate and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low electronic conductivity, large particle size, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

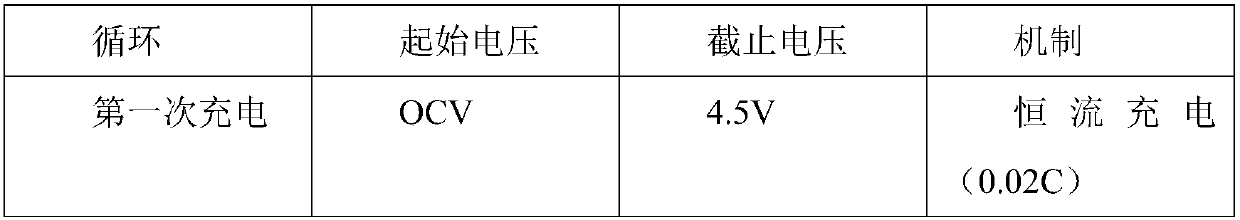

Embodiment 1

[0073] A Mn-doped Li 5 FeO 4 Lithium supplement Li 5 Fe 1-x mn x o 4 A preparation method for a lithium-ion battery supplemented with lithium, comprising the following steps:

[0074] 1. Li 5 Fe 1-x mn x o 4 Preparation of:

[0075] (1) Fe 2 o 3 , MnC 2 o 4 2H 2 O. Li 2 CO 3 According to the molar ratio of 4.5:1:25, it is dispersed in dodecyl (hexa) alkyl trimethyl ammonium bromide (dodecyl (hexa) alkyl trimethyl ammonium bromide is Fe 2 o 3 2% of the mass) in deionized water for 1 h, and the ball milling speed is 200r / min;

[0076](2) Spray-dry the slurry obtained in step (1) at 160°C to obtain a uniformly mixed precursor, and the feed rate is 30ml / min;

[0077] (3) Place the precursor obtained in step (2) in an inert atmosphere and sinter at 650°C for 24 hours, and after cooling, the initial charge capacity is 460mAh g -1 , the first charge and discharge efficiency is 10%, the particle size is 9μm, and the specific surface area is 240m 2 g -1 Li 5 Fe ...

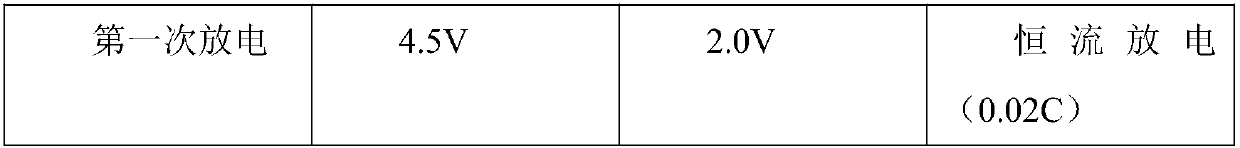

Embodiment 2

[0086] A Mn-doped Li 5 FeO 4 Lithium supplement Li 5 Fe 1-x mn x o 4 A preparation method for a lithium-ion battery supplemented with lithium, comprising the following steps:

[0087] 1. Li 5 Fe 1-x mn x o 4 Preparation of:

[0088] (1) Fe 2 o 3 , MnC 2 o 4 2H 2 O. Li 2 CO 3 According to the molar ratio of 5.5:1:25, it is dispersed in stearic acid containing stearic acid (stearic acid is Fe 2 o 3 4% of the mass) in deionized water for 2 hours, the ball milling speed is 250r / min;

[0089] (2) Spray-dry the slurry obtained in step (1) at 170°C to obtain a uniformly mixed precursor, and the feed rate is 25ml / min;

[0090] (3) Place the precursor obtained in step (2) in an inert atmosphere and sinter at 700°C for 36 hours, and after cooling, the initial charge capacity of 550mAh·g is obtained. -1 , the first charge and discharge efficiency is 9%, the particle size is 7μm, and the specific surface area is 480m 2 g -1 Li 5 Fe 1-x mn x o 4 .

[0091] 2. LiC...

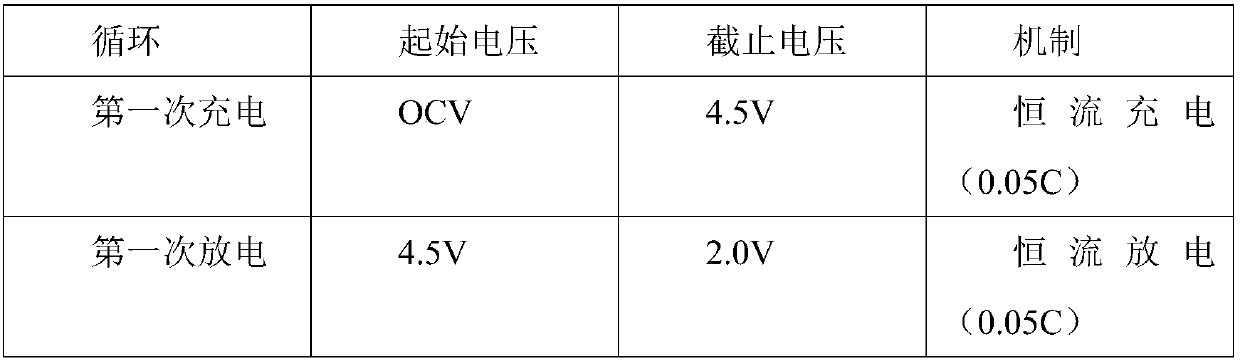

Embodiment 3

[0098] A Mn-doped Li 5 f e o 4 Lithium supplement Li 5 Fe 1-x mn x o 4 A preparation method for a lithium-ion battery supplemented with lithium, comprising the following steps:

[0099] 1. Li 5 Fe 1-x mn x o 4 Preparation of:

[0100] (1) Fe 2 o 3 , MnC 2 o 4 2H 2 O. Li 2 CO 3 According to the molar ratio of 6.5:1:25, it is dispersed in stearic acid containing stearic acid (stearic acid is Fe 2 o 3 6% of the mass) in deionized water for 3h, the ball milling speed is 300r / min;;

[0101] (2) spray-dry the slurry obtained in step (1) at 180°C to obtain a uniformly mixed precursor, and the feed rate is 20ml / min;

[0102] (3) Place the precursor obtained in step (2) in an inert atmosphere and sinter at 750°C for 48 hours, and after cooling, the initial charge capacity is 620mAh g -1 , the first charge and discharge efficiency is 7%, the particle size is 5μm, and the specific surface area is 550m 2 g -1 Li 5 Fe 1-x mn x o 4 .

[0103] 2. LiCoO 2 (75wt%),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com