Borosilicate rare earth luminescent microcrystalline glass, and preparation method and application thereof

A rare earth luminescence and borosilicate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor stability of LED phosphors, reduced white light luminous efficiency, and different anti-aging performance, and achieve good photoluminescence performance , good color uniformity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing borosilicate rare earth luminescent glass-ceramics described in the above technical solution, comprising the following steps:

[0035] According to the chemical composition of borosilicate rare earth luminescent glass-ceramic, the oxide of Ln, Bi 2 o 3 、GeO 2 , oxides of RE, carbonates of M, Al 2 o 3 , SiO 2 and H 3 BO 3 Mixing and ball milling to obtain the mixed material;

[0036] Calcining and quenching the mixed material in sequence to obtain a precursor glass;

[0037] The precursor glass is sequentially annealed and polished to obtain borosilicate rare earth luminescent glass-ceramics.

[0038] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0039] According to the chemical composition of the present invention, the oxides of Ln, Bi, Ge and RE, the carbonate of M, Al 2 o 3 , SiO 2 and ...

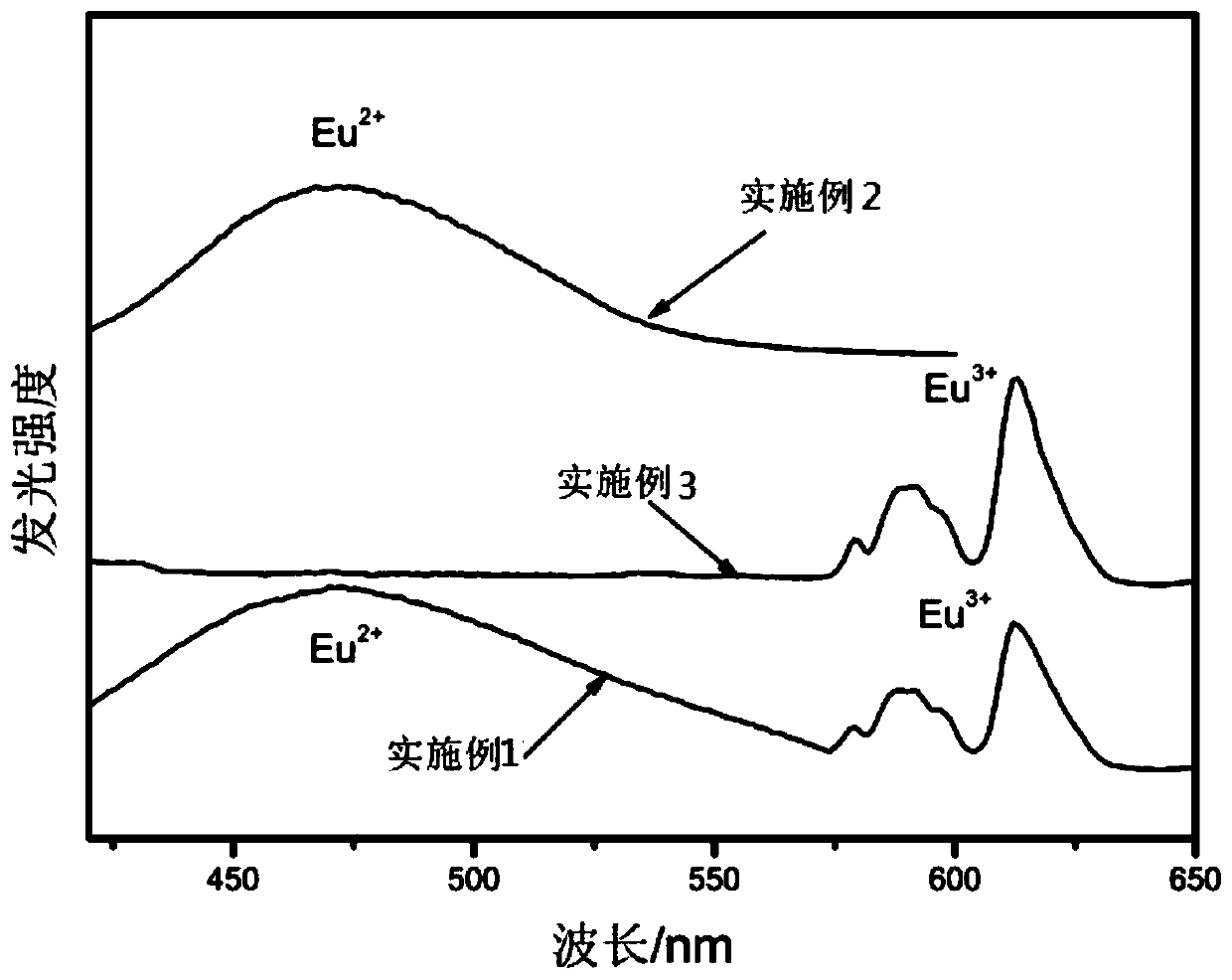

Embodiment 1

[0050] The chemical composition is 30CaO·MgO·5Y 2 o 3 25B 2 o 3 50SiO2 2 0.05Al 2 o 3 : Preparation of 0.01Bi, 0.01Ge, 0.2Eu borosilicate rare earth luminescent glass-ceramics:

[0051] 3003g CaCO 3 , 84.3g MgCO 3 , 1129g Y 2 o 3 , 3092g H 3 BO 3 , 3005g SiO 2 , 5.1g Al 2 o 3 , 2.3g Bi 2 o 3 , 1.1g GeO 2 and 35.2g Eu 2 o 3 Put into a ball mill barrel, carry out ball milling for 8 hours, calcinate the obtained mixed material at 1650° C. in an air atmosphere for 0.5 hours, quench the obtained material to obtain a precursor glass; then reduce the precursor glass at 700° C. Mixed gas with nitrogen, the volume ratio of hydrogen and nitrogen is 0.75:1) and carry out annealing treatment 6h; Gained glass is naturally cooled, then polished on a 100-mesh polishing plate for 0.5h; polished on a 500-mesh polishing plate for 1h; finally Polishing on a 1000-mesh polishing plate for 2 hours, washing the obtained glass three times with water and three times with ethanol to...

Embodiment 2

[0054] The chemical composition is 30CaO·MgO·5Y 2 o 3 25B 2 o 3 50SiO2 2 0.05Al 2 o 3 : Preparation of 0.01Bi, 0.01Ge, 0.2Eu borosilicate rare earth luminescent glass-ceramics:

[0055] 3003g CaCO 3 , 84.3g MgCO 3 , 1129g Y 2 o 3 , 3092g H 3 BO 3 , 3005g SiO 2 , 5.1g Al 2 o 3 , 2.3g Bi 2 o 3 , 1.1g GeO 2 and 35.2g Eu 2 o 3 Put into a ball mill barrel, carry out ball milling for 8 hours, and calcinate the obtained mixture material at 1650° C. in an air atmosphere for 0.5 hours, quench the obtained material to obtain a precursor glass; then reduce the precursor glass at 900° C. in a reducing atmosphere (hydrogen gas Mixed gas with nitrogen, the volume ratio of hydrogen and nitrogen is 0.75:1) and carry out annealing treatment 6h; Gained glass is naturally cooled, then polished on a 100-mesh polishing plate for 0.5h; polished on a 500-mesh polishing plate for 1h; finally Polishing on a 1000-mesh polishing plate for 2 hours, washing the obtained glass three tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com