Multi-channel total-silicon-based infrared thermoelectric detector and manufacturing method thereof

A technology of pyroelectric detectors and manufacturing methods, which is applied in the field of photoelectric detection, can solve problems such as low quantum efficiency and detection rate, inability to work with silicon materials, and high dark current, and achieve the effects of improving photocurrent, perfect absorption, and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

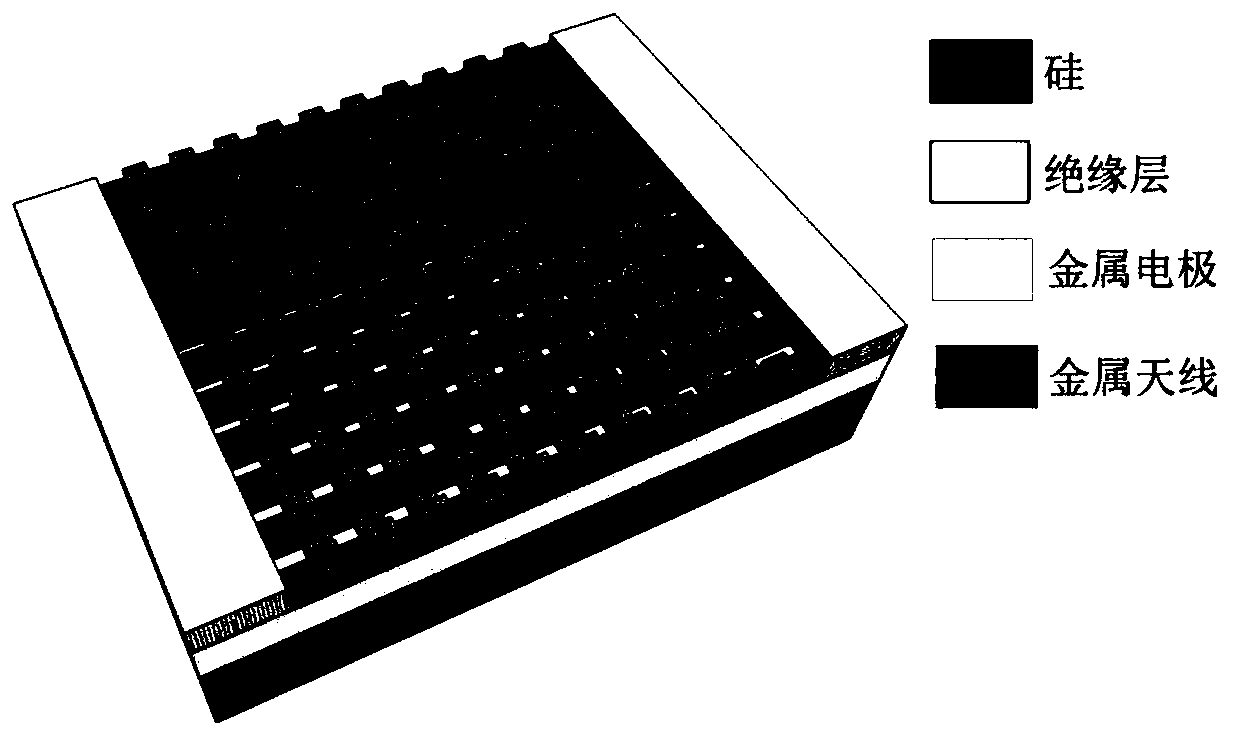

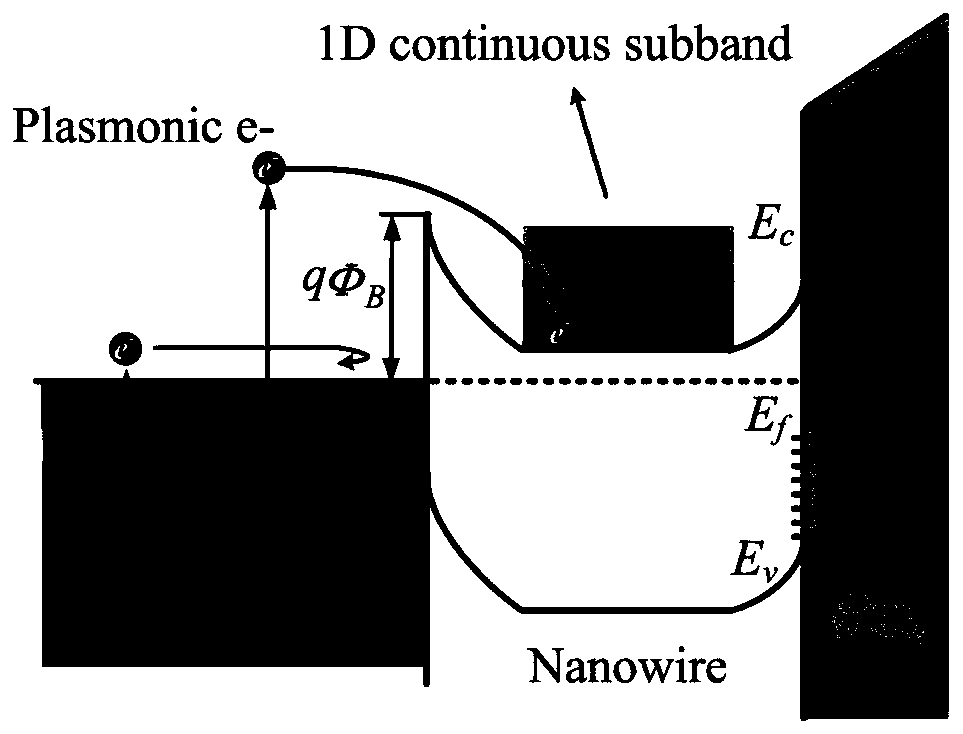

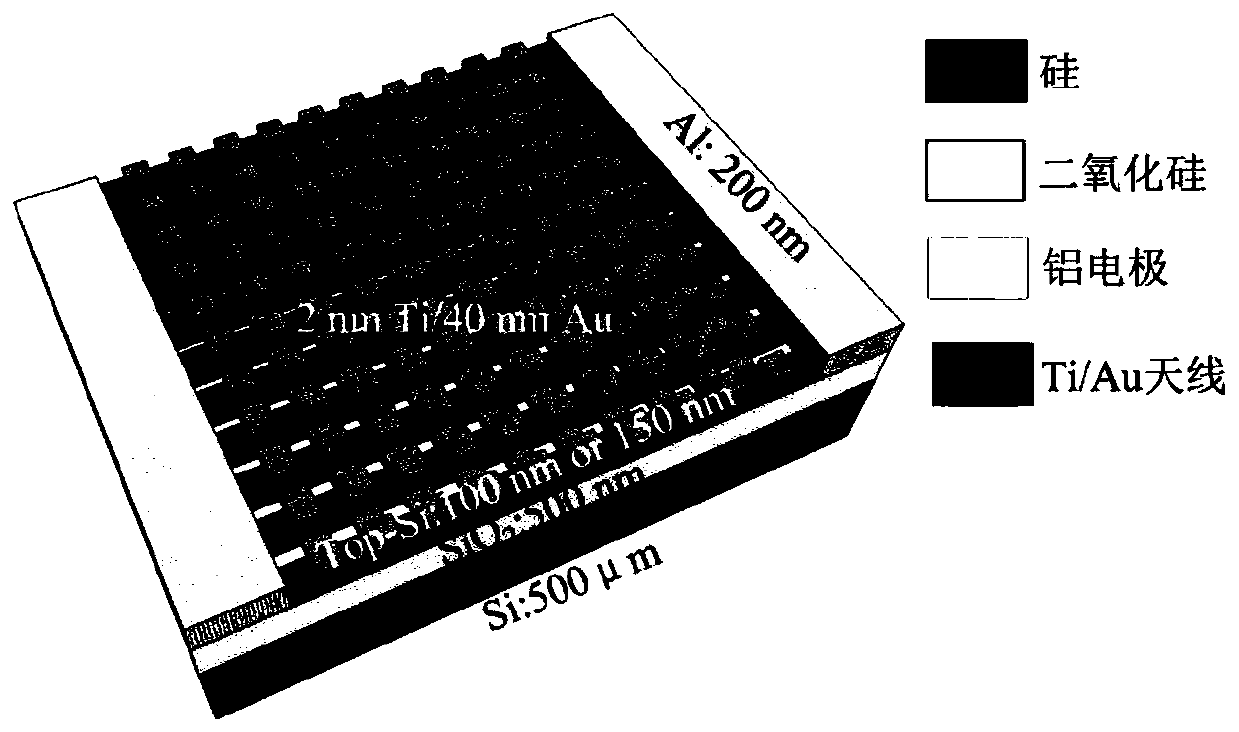

[0059] refer to image 3 As shown, it is a specific embodiment of the present invention, and the whole device structure includes:

[0060] A silicon-on-insulator (SOI) substrate, the thickness of the silicon on the top layer of the substrate is 150 nanometers and 200 nanometers, which is almost intrinsically doped with phosphorus ions, and the doping concentration is 2.8×10 15 cm -3 ; The middle layer is silicon oxide with a thickness of 500 nanometers; the bottom layer is ordinary low-doped n-type silicon with a thickness of 500 microns;

[0061] An array of silicon nanowires distributed in parallel, the silicon nanowires are prepared on the oxide layer and in the top layer of silicon; the nanowire line width is 100 and 150 nanometers, the period is 200 and 400 nanometers, the length is 300 microns, and the overall width of the distribution is is 200 microns;

[0062] A metasurface construction consisting of nanoscale metal antennas. The material is Ti / Au, where the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com