Fe-doped hydroxyl cobalt phosphite nanosheet array structure material as well as preparation method and application thereof

A technology for nanosheet arrays and structural materials, applied in the field of Fe-doped cobalt hydroxyphosphite nanosheet array structural materials and its preparation, can solve the problems of complex preparation methods and low catalytic activity, and achieve environmentally friendly and low-cost preparation processes , excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

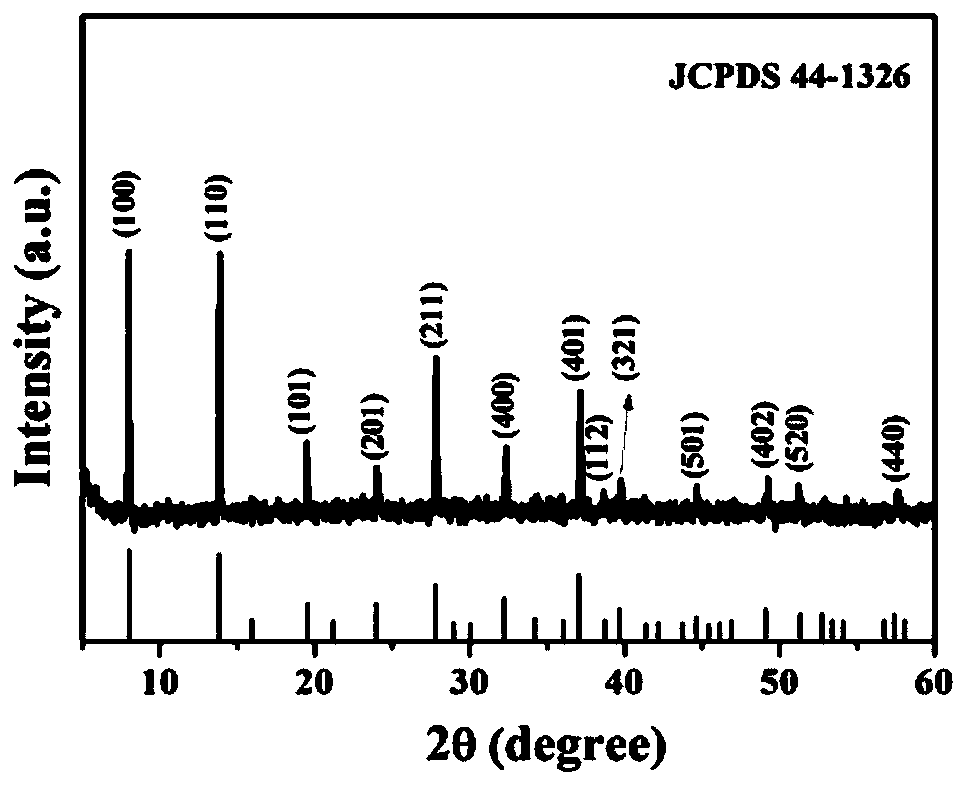

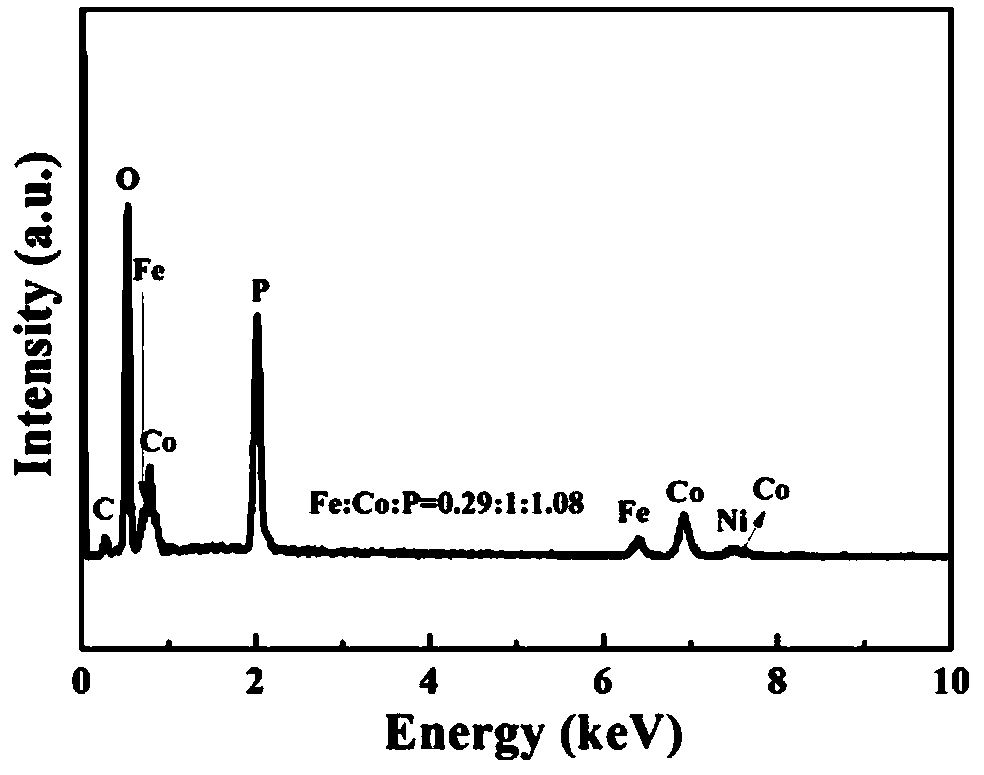

[0048] An Fe-doped Co 11(HPO 3 ) 8 (OH) 6 A method for preparing a nanosheet array structure material, comprising the following steps:

[0049] Soak 2×3cm foam nickel in 6M hydrochloric acid solution, after 15 minutes, wash the foam nickel three times with deionized water and absolute ethanol, and dry to obtain surface-clean foam nickel. Accurately measure 10mL deionized water and 30mL isopropanol into a clean small beaker, then weigh 0.6mmol Fe(NO 3 ) 3 9H 2 O, 1mmol Co(NO 3 ) 2 ·6H 2 O and 1mmol NaH 2 PO 2 ·6H 2 O was added to a small beaker, stirred and dissolved for 30 minutes to obtain a uniform solution. Transfer the solution to a 50mL polytetrafluoroethylene-lined stainless steel reaction kettle, insert the pre-treated nickel foam obliquely into the solution, seal and react in an oven at 160°C for 6 hours, and cool naturally to room temperature after the reaction is completed. The nickel foam covering the sample was washed three times with deionized water a...

Embodiment 2

[0059] Fe-doped Co 11 (HPO 3 ) 8 (OH) 6 A method for preparing a nanosheet array structure material, comprising the following steps:

[0060] Accurately measure 10mL deionized water and 30mL isopropanol into a clean small beaker, then weigh 0.4mmol or 0.8mmol Fe(NO 3 ) 3 9H 2 O, 1mmol Co(NO 3 ) 2 ·6H 2 O and 1mmol NaH 2 PO 2 ·6H 2 O was added to a small beaker and stirred evenly. Insert the dried nickel foam obliquely into a 50mL polytetrafluoroethylene-lined stainless steel reactor. After the solution is fully dissolved, transfer it to the reactor, seal it and react in an oven at 160°C for 6 hours. After the reaction is complete, cool down to room temperature naturally, wash the nickel foam covering the sample several times with deionized water and absolute ethanol, then place the nickel foam covering the sample to dry naturally in an air atmosphere, and the Fe(NO 3 ) 3 9H 2 When the addition amount of O was 0.4 mmol, the obtained Fe-doped Co 11 (HPO 3 ) 8 (...

Embodiment 3

[0065] An Fe-doped Co 11 (HPO 3 ) 8 (OH) 6 Applications of nanosheet structured materials as oxygen evolution reaction (OER) catalysts.

[0066] The specific application method is: doping Fe with an area of 0.5×0.5cm into Co 11 (HPO 3 ) 8 (OH) 6 The nanosheet structure material was used as the working electrode, platinum wire and Ag / AgCl electrode were used as the counter electrode and reference electrode respectively, and the CHI760E electrochemical workstation was used for testing in 1.0M KOH electrolyte solution. commercial RuO 2 and Co 11 (HPO 3 ) 8 (OH) 6 Nanosheets were loaded on nickel foam as working electrodes, and their OER performances were measured for comparison. Co 11 (HPO 3 ) 8 (OH) 6 The preparation is to omit the Fe(NO in the raw material on the basis of embodiment 1 3 ) 3 9H 2 O prepared. Using linear sweep voltammetry (LSV) at 2.0mV s -1 Polarization curves were obtained at a scan rate of 90% and an ohmic compensation of 90%.

[0067] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com