Reduced graphene oxide/nano-TiO2 composite demulsifier and preparation method thereof

A composite demulsification and graphene technology, which is applied in the direction of chemical dehydration/demulsification, graphene, titanium oxide/hydroxide, etc., can solve the problem of poor demulsification performance, toxic and harmful substances, and polymer demulsifiers. Degradation and other problems, to achieve high salt resistance, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

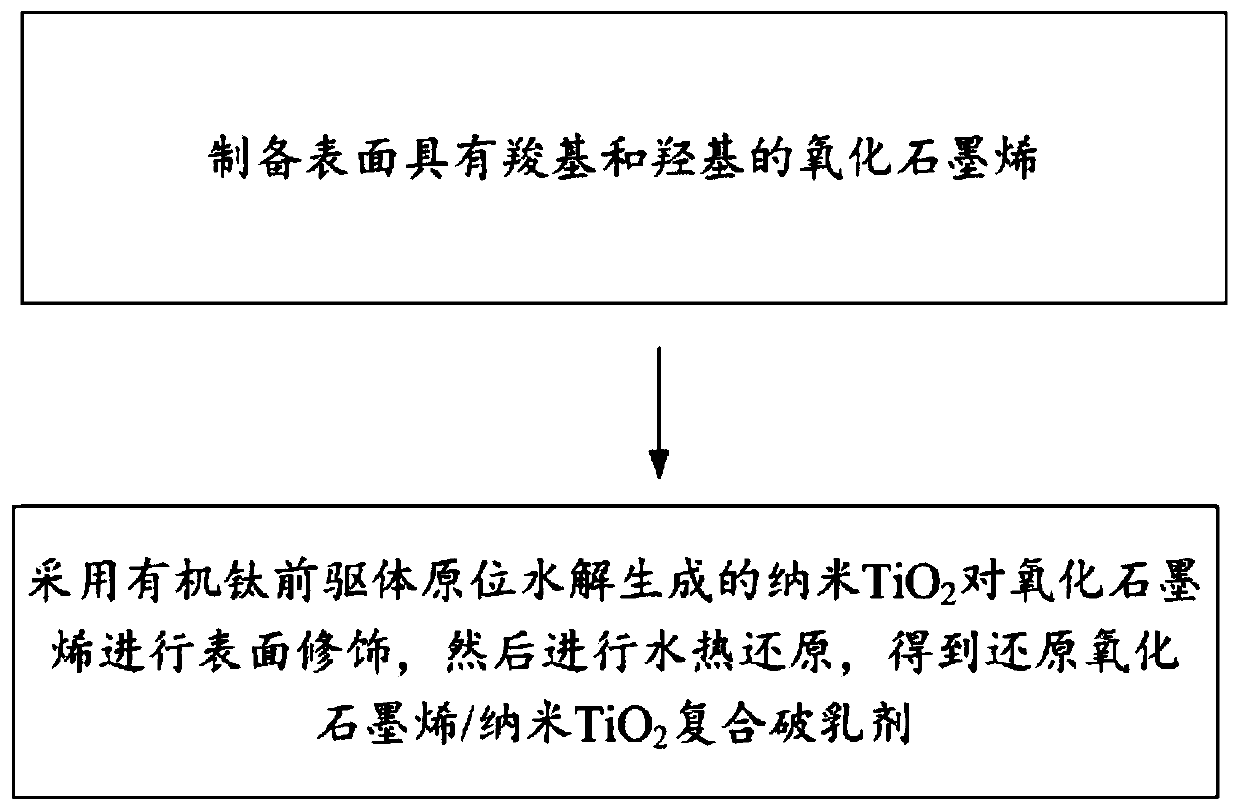

[0019] Such as figure 1 , figure 1 It is the reduced graphene oxide / nano-TiO of the present invention 2 Flow chart of the preparation method of the composite demulsifier. In the first aspect, the present invention provides a reduced graphene oxide / nano-TiO 2 The preparation method of compound demulsifier, described method comprises the following steps:

[0020] (1) prepare the graphene oxide that surface has carboxyl group and hydroxyl group;

[0021] (2) Nano-TiO generated by in-situ hydrolysis of organic titanium precursors 2 Carry out surface modification to described graphene oxide, carry out hydrothermal reduction then, obtain reduced graphene oxide / nanometer TiO 2 Compound demulsifier.

[0022] According to the present invention, the described preparation surface of step (1) has the graphene oxide of carboxyl group and hydroxyl group, comprises the following steps:

[0023] (a) 25 parts by weight of NaNO 3 , 20 parts by weight of flake graphite and 180 parts by w...

Embodiment 1

[0050] This embodiment provides a reduced graphene oxide / nano-TiO 2 Composite demulsifier, described demulsifier obtains through the following steps:

[0051] 25 parts by weight of NaNO 3 and 20 parts by weight of graphite flakes were added to 180 parts by weight of 95% concentrated H 2 SO 4 , stir evenly to obtain the mixed solution I; slowly add 15 parts by weight of KMnO to the above mixed solution I 4 , and control the temperature of the reaction mixture at 13°C, and then continuously stir at room temperature for 24 hours, then add 180 parts by weight of deionized water to obtain the mixed solution II; raise the temperature of the above mixed solution II to 100°C and keep it warm for 1 hour , followed by cooling to 70°C, adding 80 parts by weight of 35% H 2 o 2 , mixed evenly, continued to react for 1 h after natural cooling to room temperature, after the reaction was completed, the graphene oxide sol was obtained by washing and centrifuging.

[0052] Add 20 parts by...

Embodiment 2

[0055] This embodiment provides a reduced graphene oxide / nano-TiO 2 Composite demulsifier, described demulsifier obtains through the following steps:

[0056] 25 parts by weight of NaNO 3 and 20 parts by weight of graphite flakes were added to 180 parts by weight of 95% concentrated H 2 SO 4 , stir evenly to obtain the mixed solution I; slowly add 15 parts by weight of KMnO to the above mixed solution I 4 , and control the temperature of the reaction mixture at 15°C, then continuously stir at room temperature for 24 hours, then add 180 parts by weight of deionized water to obtain the mixed solution II; raise the temperature of the above mixed solution II to 100°C and keep it warm for 1 hour , followed by cooling to 70°C, adding 80 parts by weight of 35% H 2 o 2 , mixed evenly, continued to react for 1 h after natural cooling to room temperature, after the reaction was completed, the graphene oxide sol was obtained by washing and centrifuging.

[0057] Add 20 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com