Method for preparing 2,6-dichlorobenzonitrile by 2,6-dichlorobenzyl ammonioiodination

A technology of dichlorobenzylamine and dichlorobenzonitrile, which is applied in the field of preparation of chemical raw material 2,6-dichlorobenzonitrile, can solve the problems of long route, low total yield and high production cost of the hydroxamoximation method, Achieve the effects of improving industrial production efficiency, no by-product pollution, and reducing industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

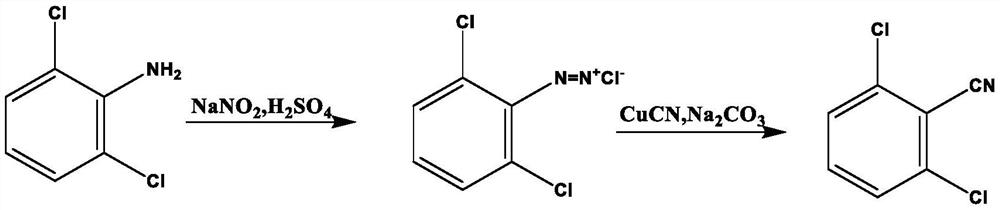

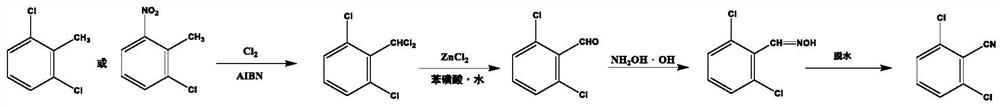

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In a 150 mL hydration kettle, 2 g of 2,6-dichlorobenzyl chloride, 60 mL of ammonia water, 7.62 g of iodine elemental substance, and 0.6 g of cetyltrimethylammonium chloride were added. After the reactor was sealed, stirring was started, and nitrogen was used to replace it three times. The temperature was raised to 70°C, and the reaction time was 9h, and the yield of 2,6-dichlorobenzonitrile was 97.7%.

Embodiment 2

[0033]In a 150 mL hydration kettle, 2 g of 2,6-dichlorobenzyl chloride, 60 mL of ammonia water, 7.62 g of iodine elemental substance, and 0.6 g of tetramethylammonium chloride were added. After the reactor was sealed, stirring was started, and nitrogen was used to replace it three times. The temperature was raised to 70° C., the reaction time was 9 h, and the yield of 2,6-dichlorobenzonitrile was 97.5%.

Embodiment 3

[0035] In a 150 mL hydration kettle, 2 g of 2,6-dichlorobenzyl chloride, 60 mL of ammonia water, 7.62 g of iodine, and 7.25 g of ammonium iodide were added. After the reactor was sealed, stirring was started, and nitrogen was used to replace it three times. The temperature was raised to 70° C., the reaction time was 9 h, and the yield of 2,6-dichlorobenzonitrile was 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com