Special culture medium for streptococcus for producing sodium hyaluronate and preparation method thereof

A technology of sodium hyaluronate and culture medium, applied in the biological field, can solve problems such as the inability to meet industrial production needs, achieve good application prospects, break through the bottleneck of technological development, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

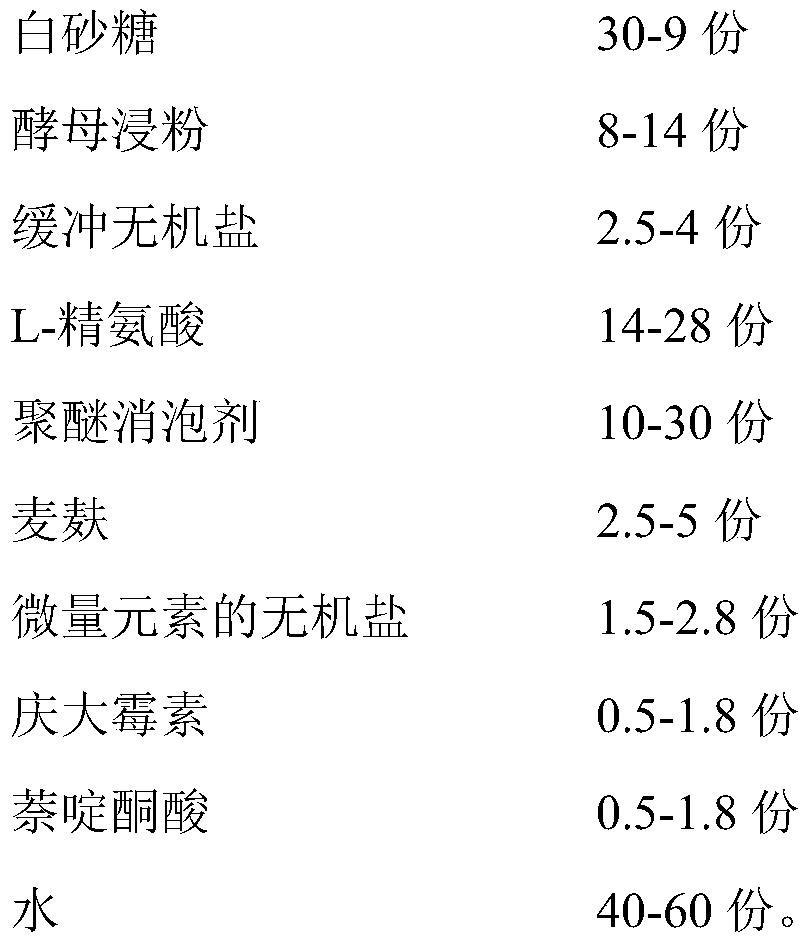

[0032] A streptococcus special culture medium for producing sodium hyaluronate, in parts by weight, comprises the following components:

[0033]

[0034] The preparation method of the streptococcus special medium for producing sodium hyaluronate comprises the following steps:

[0035] (1) Weigh each component according to the ingredient list, dissolve white sugar, yeast extract powder and wheat bran in water, and mix at 20°C for 20 minutes to obtain the first mixed solution;

[0036] (2) dissolving buffering inorganic salts, inorganic salts of trace elements, L-arginine, gentamicin, and nalidixic acid in water, and mixing at 50° C. for 10 minutes to obtain a second mixed solution;

[0037] (3) Mix the first mixed solution, the second mixed solution and the polyether antifoaming agent at 30° C. for 5 minutes to a clear state to obtain the culture medium.

Embodiment 2

[0039] A streptococcus special culture medium for producing sodium hyaluronate, in parts by weight, comprises the following components:

[0040]

[0041] The preparation method of the streptococcus special medium for producing sodium hyaluronate comprises the following steps:

[0042] (1) Weigh each component according to the ingredient list, dissolve white sugar, yeast extract powder and wheat bran in water, and mix at 40°C for 50 minutes to obtain the first mixed solution;

[0043] (2) Dissolving buffer inorganic salts, inorganic salts of trace elements, L-arginine, gentamicin, and nalidixic acid in water, and mixing at 70° C. for 22 minutes to obtain a second mixed solution;

[0044] (3) Mix the first mixed solution, the second mixed solution, and the polyether antifoaming agent at 33° C. for 14 minutes to a clear state to obtain the culture medium.

Embodiment 3

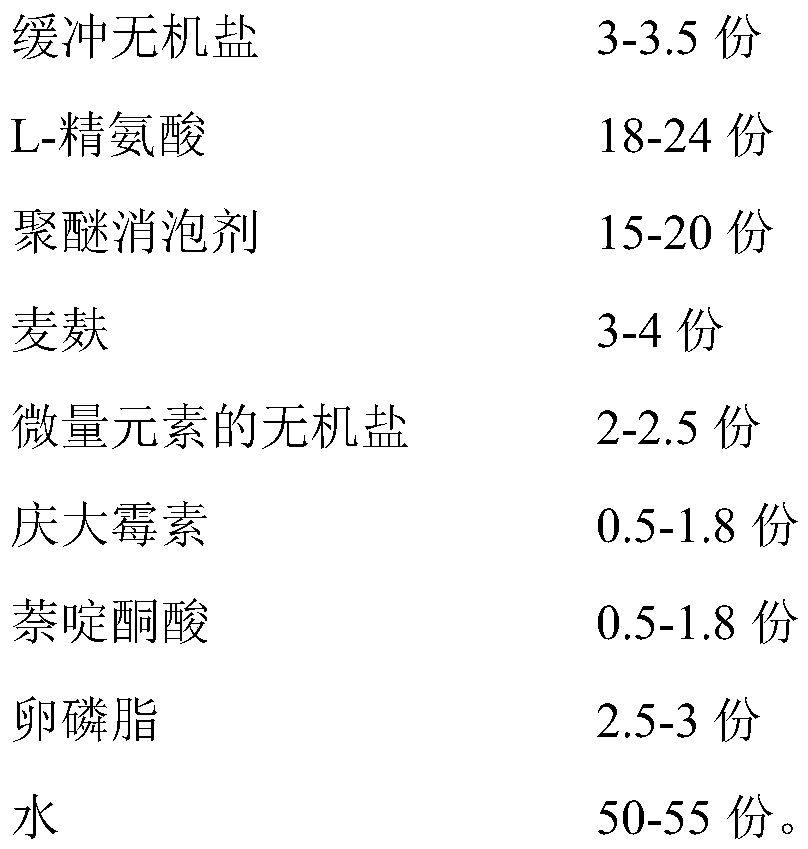

[0046] A streptococcus special culture medium for producing sodium hyaluronate, in parts by weight, comprises the following components:

[0047]

[0048]

[0049] The preparation method of the streptococcus special medium for producing sodium hyaluronate comprises the following steps:

[0050] (1) Weigh each component according to the ingredient list, dissolve white sugar, yeast extract powder and wheat bran in water, and mix at 20°C for 20 minutes to obtain the first mixed solution;

[0051] (2) dissolving buffering inorganic salts, inorganic salts of trace elements, L-arginine, gentamicin, and nalidixic acid in water, and mixing at 50° C. for 10 minutes to obtain a second mixed solution;

[0052] (3) Mix the first mixed solution, the second mixed solution and the polyether antifoaming agent at 30° C. for 5 minutes to a clear state to obtain the culture medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com