Sample processing device for soil heavy metal detection and processing method thereof

A sample processing and soil sample technology, applied in the field of soil detection, can solve the problems of rough processing, low efficiency, and affecting the accuracy of soil heavy metal detection, and achieve the effect of complete digestion, good processing effect and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

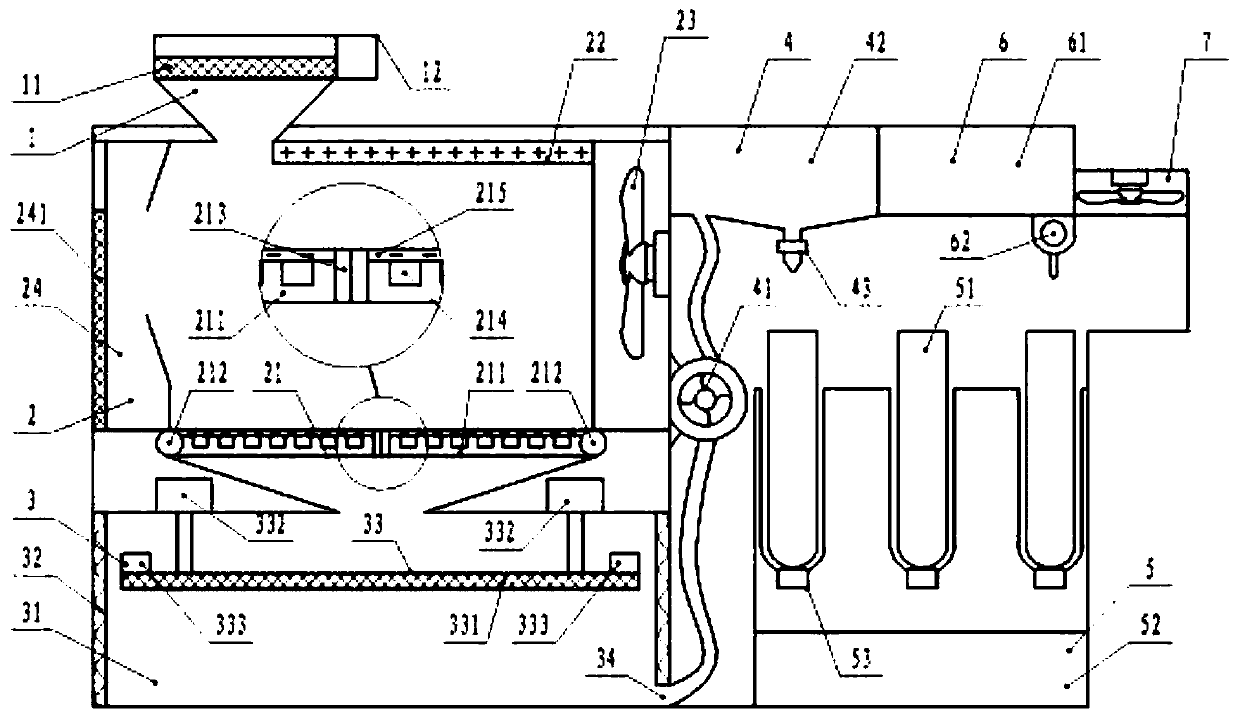

[0027] Example: such as figure 1 As shown, a sample processing device for heavy metal detection in soil mainly includes a hopper 1, a screening device 2, a pretreatment device 3, a distribution device 4, a sample rack 5 and a digestion device 6, and the hopper 1 is used for dissolving the soil Sampling is sent to the screening device 2, the hopper 1 is provided with a screen 11 for removing larger impurities in the soil, and the outside of the hopper 1 is provided with a vibrator 12 at the position corresponding to the screen 11.

[0028] The screening device 2 includes a separation base 21 for separating the soil from the plant residues in the soil and charging the plant residues. The separation base 21 is made up of two vibration plates 211, and the outside of the vibration plates 211 is provided with a control vibration plate 211 rotation Two rotating motors 212, two electromagnetic devices 213 that are connected to each other are respectively provided at the joints of the ...

experiment example

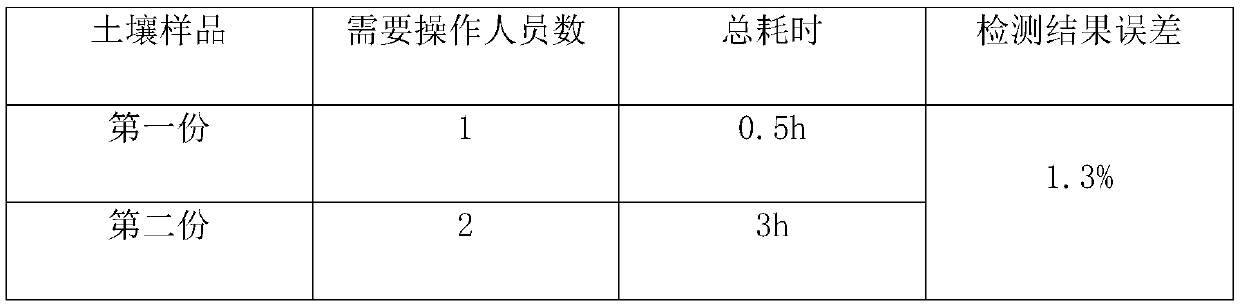

[0040] The purpose of the experiment: To study the effect of the processing device provided in the implementation on the test results of soil samples.

[0041] Experimental conditions: A soil sample taken from the same place was divided into two parts on average. The first part was processed with the processing device provided in the example, and the second part was processed by manually picking out plant residues in the soil and manually digesting them. The same test was carried out on the two treated soil samples, and the test results were analyzed. The experimental results are shown in Table 1.

[0042] Table 1 Detection table of different treatment methods

[0043]

[0044] Conclusion: Using the device provided in this embodiment to pretreat the soil before testing will not affect the accuracy of the testing results, save time and effort, and have a high degree of automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com