A hydrogen generation device and method based on pressure control, and fuel cell system

A generation device and pressure control technology, applied in hydrogen production, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problem that hydrogen production and storage devices cannot be used on a large scale, and hydrogen production and storage devices are prone to explosion and corrosion Container safety and other issues, to achieve the effect of increasing the rate of hydrolysis reaction, the overall structure is simple, easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

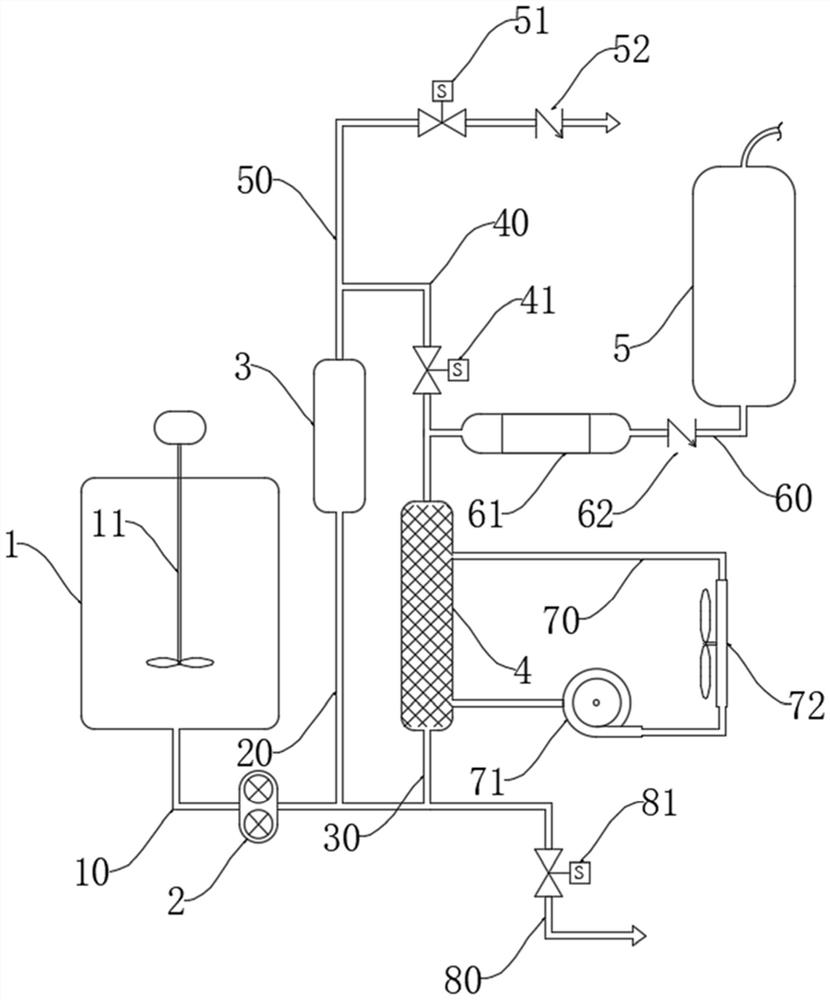

[0043] like Figures 1 to 6 As shown, this embodiment discloses a hydrogen generating device based on pressure control, which can safely and conveniently realize the function of hydrogen production and storage (hydrogen production and hydrogen storage), and can provide hydrogen for hydrogen fuel cells in military equipment, etc. The raw materials are specified as follows.

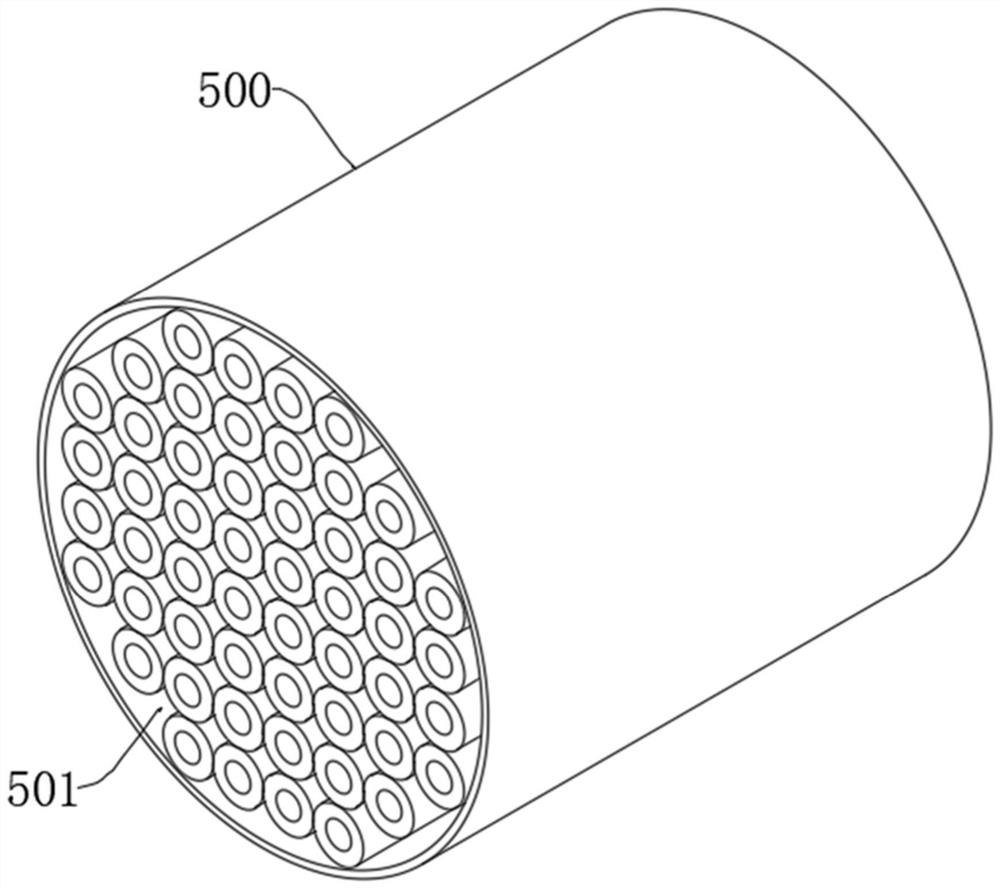

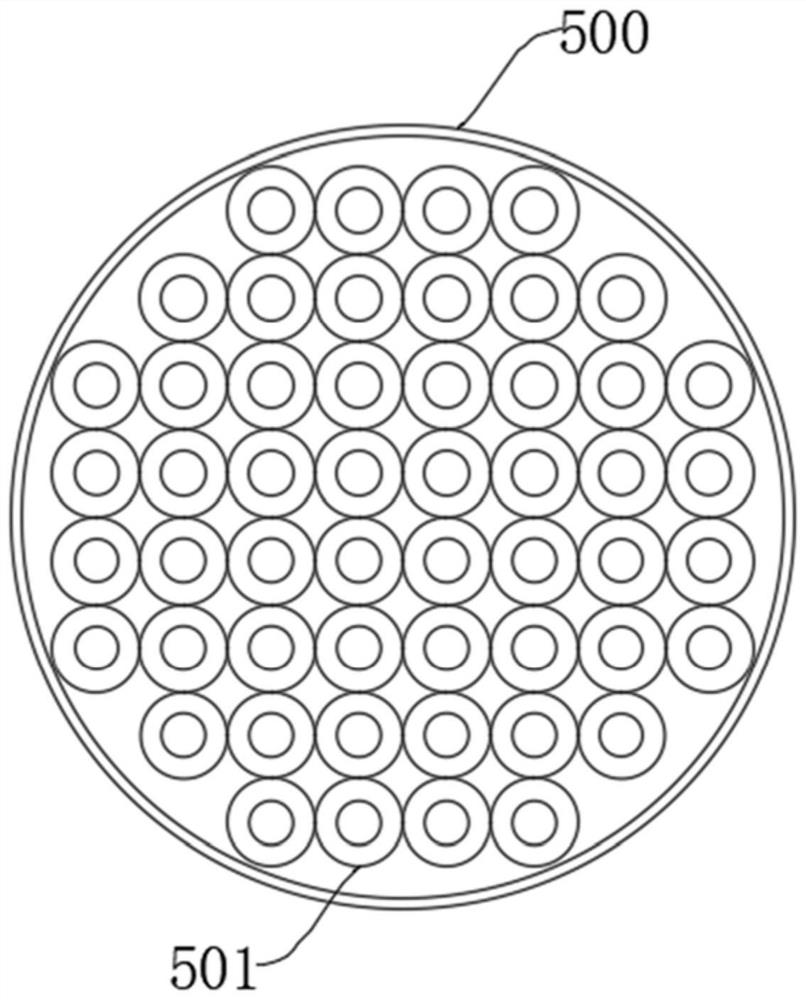

[0044] like figure 1 , 5 , 6, the hydrogen generating device includes a sodium borohydride liquid storage tank 1, a solution filling pump 2, a buffer tank 3, a hydrolysis hydrogen production reactor 4 and a reversible metal hydrogen storage container 5, and the sodium borohydride liquid storage tank 1 is installed There is a stirring device 11. In this embodiment, the stirring head of the stirring device 11 can be driven by a motor to move in the solution. The stirring device 11 is used to uniformly mix sodium borohydride, sodium hydroxide and water, thereby improving the late stage hydrolysis reaction ef...

Embodiment 2

[0052] Based on the same inventive concept as Embodiment 1, this embodiment provides a method for generating hydrogen based on pressure control. This embodiment will not repeat the structure of the hydrogen generating device mentioned in Embodiment 1. This embodiment uses Embodiment 1 The hydrogen generation (hydrogen production) method of the hydrogen generation device in the invention comprises the following steps.

[0053] Step 1, mix sodium borohydride and sodium hydroxide according to a preset ratio, pour the mixed sodium borohydride and sodium hydroxide into sodium borohydride storage tank 1, and then pour it into sodium borohydride storage tank 1 Add water to configure a sodium borohydride solution with a preset mass fraction. Compared with the conventional hydrogen production scheme, because the present invention can discharge the waste liquid in time, the present invention does not have high requirements for water quality; in the specific implementation process In thi...

Embodiment 3

[0062] Based on the same inventive concept as Embodiments 1 and 2, this embodiment provides a fuel cell system, which includes any pressure-controlled hydrogen generating device in Embodiment 1, that is, the fuel cell in this embodiment The system is a hydrogen fuel cell system, and the hydrogen comes from the hydrogen generating device in the first embodiment, and the hydrogen generating device in the first embodiment provides the fuel cell system with hydrogen for power generation; therefore, this embodiment is equivalent to providing a A hydrogen-air fuel cell with sodium borohydride for hydrogen production. As for the fuel cell part, it can be selected from existing fuel cells, which will not be repeated in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com