Resource utilization system and method of circuit board etching acidic waste liquid

A technology of acid waste liquid and circuit board, which is applied in the field of waste water treatment and recycling, can solve the problems of corrosion, low benefit, high equipment investment cost and high operation cost, and achieve simple maintenance, corrosion resistance of equipment, reduced maintenance cost and operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

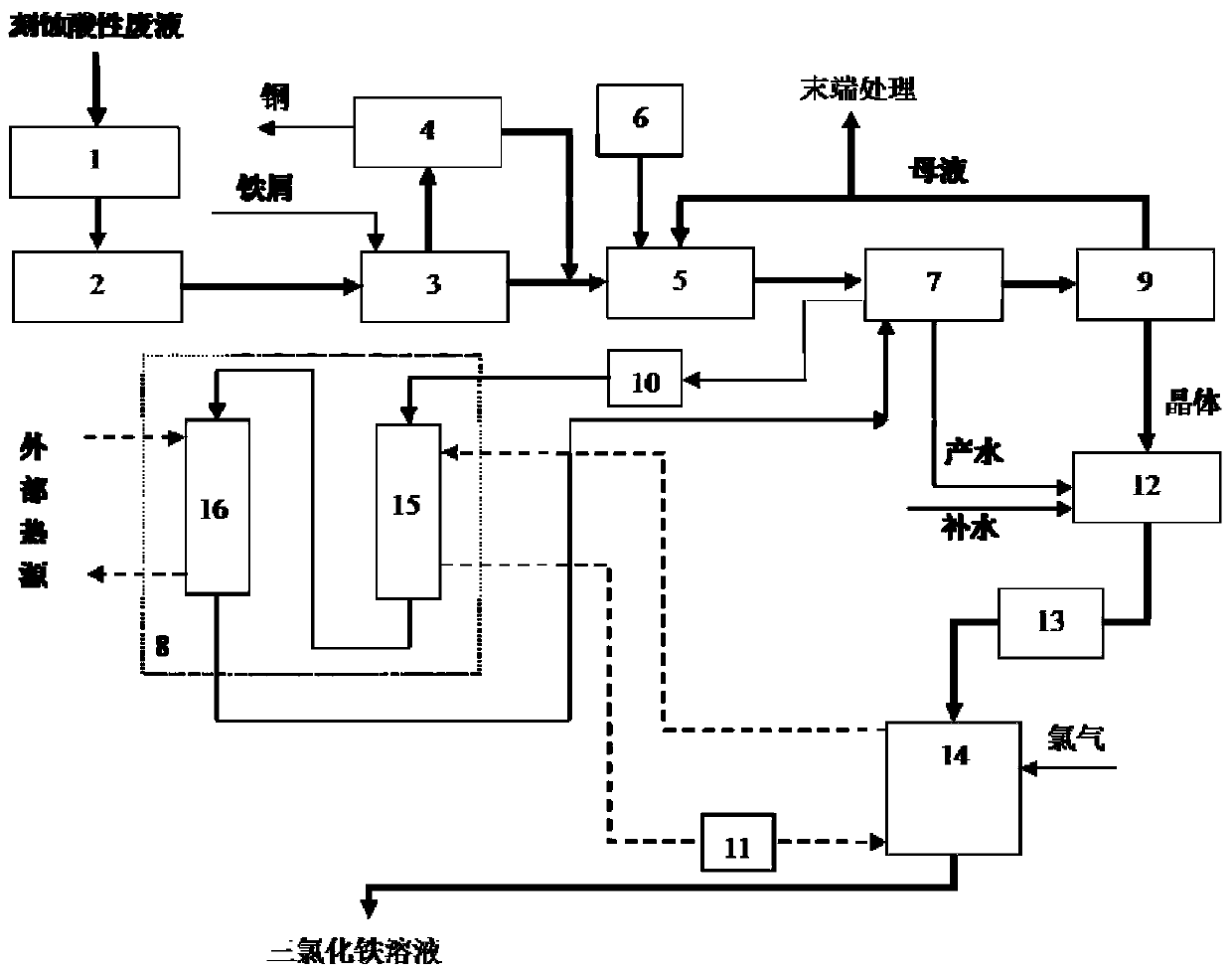

[0072] As an embodiment of the present invention, the recycling system of acid waste liquid from circuit board etching includes a pretreatment unit, a membrane distillation concentration unit, a low temperature crystallization unit and an oxidation unit;

[0073] The membrane distillation concentration unit is located downstream of the metal replacement unit; the low temperature crystallization unit is located downstream of the membrane distillation concentration unit; the oxidation unit is located downstream of the low temperature crystallization unit.

[0074] As an embodiment of the present invention, the resource recovery system of circuit board etching acid waste liquid includes a pretreatment unit, an acidity adjustment unit, a membrane distillation concentration unit, a heating unit, a low temperature crystallization unit and an oxidation unit;

[0075] The acidity adjustment unit is located upstream of the membrane distillation concentration unit; the heating unit is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com