Cement hexavalent chromium reducing agent, and preparation method thereof

A technology of hexavalent chromium and reducing agent, applied in the field of building materials, can solve the problems of easy failure, high price, genetic defects, etc., and achieve the effect of convenient use and long-term effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

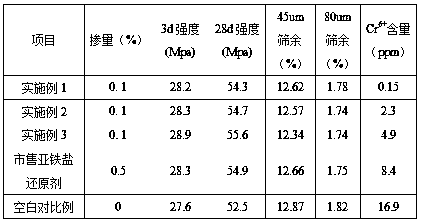

Examples

Embodiment 1

[0027] A cement hexavalent chromium reducing agent is made of the following raw materials in parts by weight: 20 parts of antimony trioxide, 5 parts of polycarboxylate hyperdispersant, 0.5 part of defoamer, and 0.3 part of hydroxypropyl methylcellulose , 90 parts of water. The antimony trioxide is an industrial product with a content of 99.5%; the defoamer is a silicone defoamer with a model of XP-17; the hydroxypropyl methylcellulose has a viscosity of 100,000. Described polycarboxylate hyperdispersant is made by following method:

[0028] 1) Put 50 parts by weight of methacrylic acid and 18 parts by weight of polyethylene glycol into a reaction vessel, add 100 parts by weight of chloroform and 0.8 parts by weight of hydroquinone, and condense in a nitrogen atmosphere at 110°C Reflux for 3.5 hours to obtain the first product;

[0029] 2) Distill the primary product at 40°C under reduced pressure to remove chloroform to obtain esterified macromonomer;

[0030] 3) Put 70 par...

Embodiment 2

[0039] A hexavalent chromium reducing agent for cement is made from the following raw materials in parts by weight: 10 parts of antimony trioxide, 3 parts of polycarboxylate hyperdispersant, 0.2 part of defoamer, and 0.1 part of hydroxypropyl methylcellulose , 80 parts of water. The antimony trioxide is an industrial product with a content of 99.5%; the defoamer is a silicone defoamer with a model of XP-17; the hydroxypropyl methylcellulose has a viscosity of 100,000. Described polycarboxylate hyperdispersant is made by following method:

[0040] 1) Put 50 parts by weight of methacrylic acid and 18 parts by weight of polyethylene glycol into a reaction vessel, add 100 parts by weight of chloroform and 0.8 parts by weight of hydroquinone, and condense in a nitrogen atmosphere at 110°C Reflux for 3.5 hours to obtain the first product;

[0041] 2) Distill the primary product at 40°C under reduced pressure to remove chloroform to obtain esterified macromonomer;

[0042] 3) Put ...

Embodiment 3

[0051] A cement hexavalent chromium reducing agent, which is made of the following raw materials in parts by weight: 5 parts of antimony trioxide, 1 part of polycarboxylate hyperdispersant, 0.2 part of defoamer, and 0.1 part of hydroxypropyl methylcellulose , 70 parts of water. The antimony trioxide is an industrial product with a content of 99.5%; the defoamer is a silicone defoamer with a model of XP-17; the hydroxypropyl methylcellulose has a viscosity of 100,000. Described polycarboxylate hyperdispersant is made by following method:

[0052] 1) Put 50 parts by weight of methacrylic acid and 18 parts by weight of polyethylene glycol into a reaction vessel, add 100 parts by weight of chloroform and 0.8 parts by weight of hydroquinone, and condense in a nitrogen atmosphere at 110°C Reflux for 3.5 hours to obtain the first product;

[0053] 2) Distill the primary product at 40°C under reduced pressure to remove chloroform to obtain esterified macromonomer;

[0054]3) Put 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com