High water-resistant wood adhesive material

A wood adhesive, water-resistant technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. The effect of improving water resistance protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

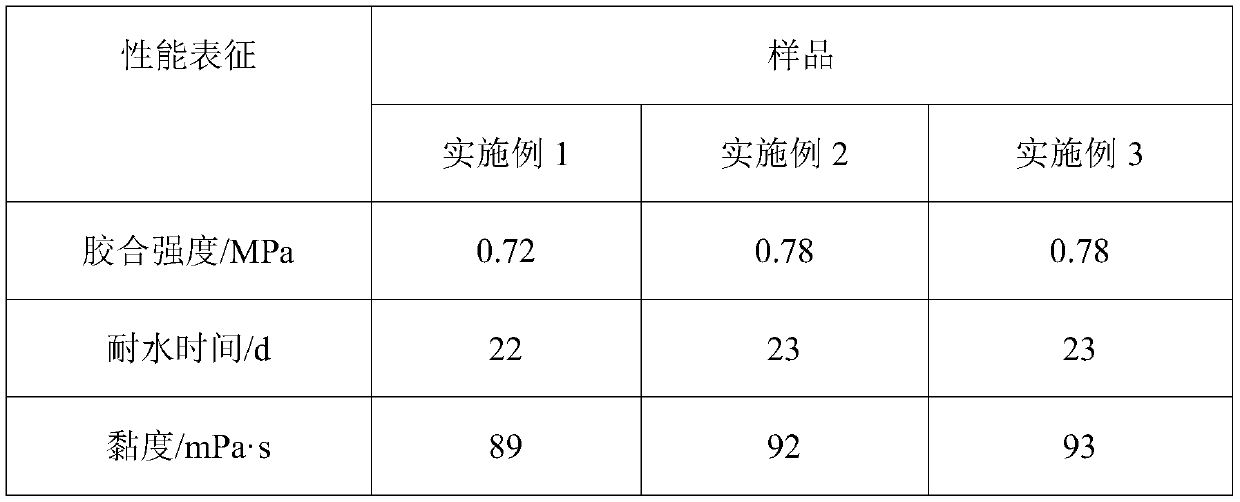

Embodiment 1

[0026] In terms of parts by weight, weigh 45 parts of polyether polyol mixture, 3 parts of plasticizer TXIB and 1 part of DOP into a three-necked flask, stir and mix, heat in an oil bath at 110°C, and evacuate to 45Pa , stirred and mixed and allowed to cool down to 55°C. The reaction solution was collected during the heat preservation reaction and counted in parts by weight. Weighed 45 parts of the reaction solution, 6 parts of isocyanate and 1 part of dibutyltin dilaurate and placed them in a three-necked flask, and stirred Mix and place at 75°C for heat preservation reaction for 2 hours, let stand and cool to 55°C, and discharge to obtain modified elastic filler; in parts by weight, weigh 45 parts of deionized water, 1 part of flat plus O, 1 1 part of Span-80 and 3 parts of polyethylene glycol were placed in a three-necked flask, stirred and mixed, and the mixture was collected. According to the mass ratio of 1:5, isobutyltriethoxysilane was added dropwise to the mixture to c...

Embodiment 2

[0028] In terms of parts by weight, weigh 47 parts of polyether polyol mixture, 4 parts of plasticizer TXIB and 1 part of DOP in a three-necked flask, stir and mix and heat in an oil bath at 115°C, and vacuumize to 47Pa , stirred and mixed and allowed to cool down to 57°C. The reaction solution was collected during the heat preservation reaction and counted in parts by weight. Weighed 47 parts of the reaction solution, 7 parts of isocyanate and 1 part of dibutyltin dilaurate and placed them in a three-necked flask. Stir Mix and place at 80°C for heat preservation reaction for 2 hours, let it stand and cool to 57°C, and discharge to obtain a modified elastic filler; in parts by weight, weigh 47 parts of deionized water, 1 part of flat plus O, 1 One part of Span-80 and 4 parts of polyethylene glycol were placed in a three-necked flask, stirred and mixed to collect the mixed material, and isobutyltriethoxysilane was added dropwise to the mixed material in a mass ratio of 1:5 to co...

Embodiment 3

[0030] In terms of parts by weight, weigh 50 parts of polyether polyol mixture, 5 parts of plasticizer TXIB and 2 parts of DOP into a three-necked flask, stir and mix, heat in an oil bath at 120°C, and evacuate to 50Pa , stir and mix and let stand to cool down to 65°C. The reaction solution collected during the heat preservation reaction is counted in parts by weight. Weigh 50 parts of the reaction solution, 8 parts of isocyanate and 2 parts of dibutyltin dilaurate and place them in a three-necked flask. Stir Mix and place at 85°C for heat preservation for 3 hours, let stand and cool to 65°C, and discharge to obtain a modified elastic filler; by weight parts, weigh 50 parts of deionized water, 2 parts of flat plus O, 2 Put one part of Span-80 and 5 parts of polyethylene glycol in a three-necked flask, stir and mix and collect the mixed material, and add isobutyltriethoxysilane dropwise to the mixed material according to the mass ratio of 1:5, and control The dropping rate is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com