Finishing method for ultraviolet-resistant water-proof anti-bacterial fabric

An anti-ultraviolet and antibacterial fabric technology, applied in the direction of fiber treatment, plant fiber, animal fiber, etc., can solve the problems of reducing the durability and washing resistance of the fabric, the textile hand feeling, the appearance of the impact, and the single anti-ultraviolet property. The effect of reducing pollution and good antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

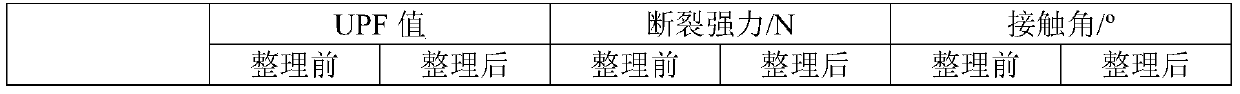

Embodiment 1

[0037] A finishing method for anti-ultraviolet, waterproof and antibacterial fabrics includes the following steps:

[0038] 1. Mix 0.3Kg ferulic acid, 0.5Kg erucic acid, 0.5Kg p-coumaric acid with 100L of water, stir well to prepare anti-ultraviolet, waterproof and antibacterial finishing solution;

[0039] 2. Dip the blended fabric into an anti-ultraviolet, waterproof and antibacterial finishing solution, dip and roll twice, with a bath ratio of 1:200, and a residual rate of 100%; then perform negative pressure flash explosion with a vacuum of 0.024mBar, and then dry at 100°C;

[0040] 3. Dip the dried blended fabric into an ozone-saturated laccase solution, the enzyme activity of laccase is 120-400U / g, the concentration of laccase is 50g / L, catalytic crosslinking is carried out at 37℃, and then dried at 100℃;

[0041] 4. Immerse the re-dried fabric in methanol solution containing lipase, the concentration of lipase (enzyme activity 1000U / g) is 30g / L, carry out the methyl esterificati...

Embodiment 2

[0043] A finishing method for anti-ultraviolet, waterproof and antibacterial fabrics includes the following steps:

[0044] 1. Mix 0.1Kg ferulic acid, 0.2Kg erucic acid, and 0.1Kg p-coumaric acid with 100L of water, stir thoroughly, and prepare an anti-ultraviolet, waterproof and antibacterial finishing solution;

[0045] 2. Dip the silk textile into an anti-ultraviolet, waterproof and antibacterial finishing solution, dip and roll twice, with a bath ratio of 1:100, and a residual rate of 80%; then perform negative pressure flash explosion with a vacuum of 0.100mBar, and then dry at 80°C ;

[0046] 3. Dip the dried silk fabric into the ozone-saturated laccase solution, the enzyme activity of laccase is 120-400U / g, the concentration of laccase is 20g / L, catalytic crosslinking is carried out at 30℃, and then dried at 80℃;

[0047] 4. Immerse the re-dried fabric in methanol solution containing lipase, the concentration of lipase (enzyme activity 1000U / g) is 10g / L, the methyl esterificati...

Embodiment 3

[0049] A finishing method for anti-ultraviolet, waterproof and antibacterial fabrics includes the following steps:

[0050] 1. Mix 0.5Kg ferulic acid, 1.0Kg erucic acid, 0.8Kg p-coumaric acid with 100L of water, stir well, and prepare an anti-ultraviolet, waterproof and antibacterial finishing solution;

[0051] 2. Dip the blended fabric into an anti-ultraviolet, waterproof and antibacterial finishing solution, dip and roll twice, with a bath ratio of 1:300, and a residual rate of 100%; then perform negative pressure flash explosion with a vacuum of 0.024mBar, and then dry at 120°C;

[0052] 3. Immerse the dried blended fabric into the ozone-saturated laccase solution, the enzyme activity of laccase is 120-400U / g, the concentration of laccase is 80g / L, catalytic crosslinking is carried out at 40℃, and then dried at 120℃;

[0053] 4. Immerse the re-dried fabric in methanol solution containing lipase, the concentration of lipase (enzyme activity 1000U / g) is 50g / L, carry out methyl esteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com