Preparation and surface treatment method of garnet-type solid electrolyte material of solid lithium battery and application

A solid electrolyte, garnet-type technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as volume energy density limitation of practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

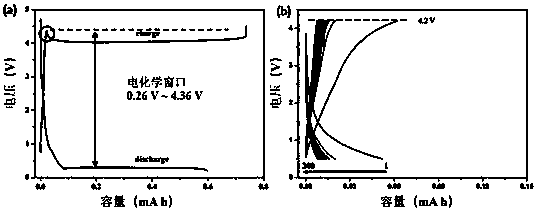

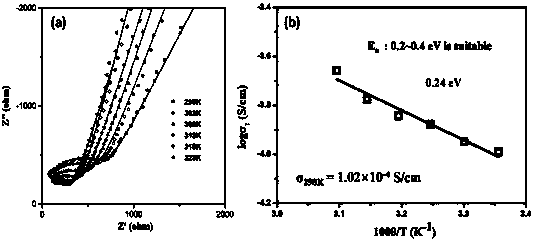

Embodiment 1

[0044] A lithium-lithium symmetric battery based on a surface-treated garnet-type solid electrolyte, including LLZO treated by ALD. First, LLZO is prepared. The material is synthesized by a solid-phase method. The steps are: using lithium hydroxide monohydrate, oxidation Lanthanum, zirconium dioxide, niobium pentoxide, and calcium carbonate were used as metal sources for preparing LLZO.

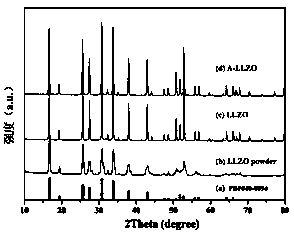

[0045] First, pre-burn lithium hydroxide monohydrate at 200°C for 6 h (in air); pre-burn lanthanum oxide at 900°C for 12 h (in air), and then according to the stoichiometric ratio (7 : 2.75 : 0.25 : 1.75 : Molar ratio of 0.25) Weigh 50 grams of lithium hydroxide monohydrate, lanthanum oxide, calcium carbonate, zirconium dioxide, and niobium pentoxide after pre-calcination, mix them and ball mill them at a speed of 1400 r / min for 30 min ( SFM-3 high-speed three-dimensional pendulum vibration ball mill, Hefei Kejing Technology Co., Ltd.), calcined at 900 ° C (in air) for 6 h in a muffle furnace...

Embodiment 2

[0054] Lithium hydroxide monohydrate, lanthanum oxide, zirconium dioxide, niobium pentoxide, and calcium carbonate were used as metal sources for preparing LLZO. First, pre-burn lithium hydroxide monohydrate at 200°C for 6 h (in air); pre-burn lanthanum oxide at 900°C for 12 h (in air), and then according to the stoichiometric ratio (7 : 2.75 : 0.25 : 1.75 : Molar ratio of 0.25) Weigh 50 grams of pre-calcined lithium hydroxide monohydrate, lanthanum oxide, calcium carbonate, zirconium dioxide, and niobium pentoxide, mix and ball mill them for 30 minutes, and use a muffle furnace at 900°C Calcined in air for 6 h, after cooling, wet ball milling with 150 ml of isopropanol, and ball milling with a planetary ball mill for 12 h to obtain cubic phase LLZO powder, and finally tableted with a pressure of 25 MPa and sintered at 1100 After sintering at ℃ (in air) for 6 h, a solid electrolyte (LLZO) was obtained. After sintering at 1100 ℃, the bulk density was lower than that at 1200 ℃, ...

Embodiment 3

[0056]A lithium-lithium symmetrical battery based on a garnet-type solid electrolyte, including a garnet-type solid electrolyte, the material is prepared by a solid-phase synthesis method, and the steps are: using lithium hydroxide monohydrate, lanthanum oxide, zirconium dioxide, Niobium and calcium carbonate were used as metal sources for preparing LLZO. First, pre-burn lithium hydroxide monohydrate at 200°C for 6 h (in air); pre-burn lanthanum oxide at 900°C for 12 h (in air), and then according to the stoichiometric ratio (7 : 2.75 : 0.25 : 1.75 : Molar ratio of 0.25) Weigh 50 grams of pre-calcined lithium hydroxide monohydrate, lanthanum oxide, calcium carbonate, zirconium dioxide, and niobium pentoxide, mix and ball mill them for 30 minutes, and use a muffle furnace at 900°C Calcined in air for 6 h, after cooling, wet ball milled with 150 ml of isopropanol, and ball milled with a planetary ball mill for 12 h to obtain cubic phase LLZO powder, and finally tableted with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com