Feather meal additive, preparation method and application

A feather meal and additive technology, which is applied in the application and introduction of foreign genetic material and hydrolase using a carrier, can solve problems such as hidden safety hazards and major amino acid damage, and achieve the effects of cleanliness, energy consumption, high solid content and high concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

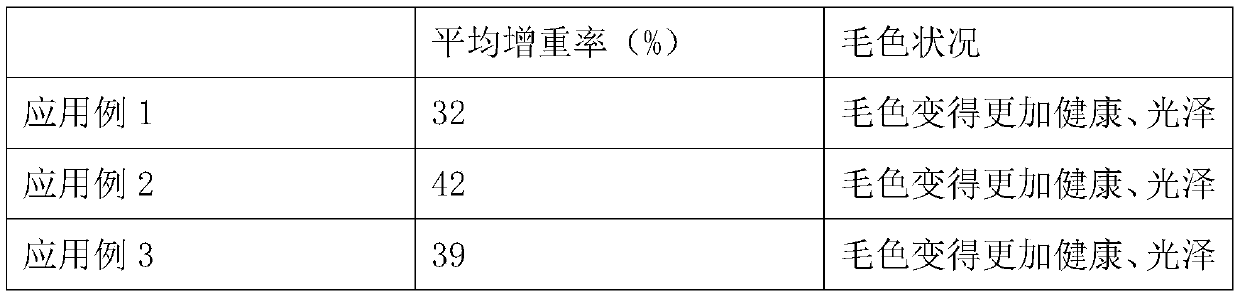

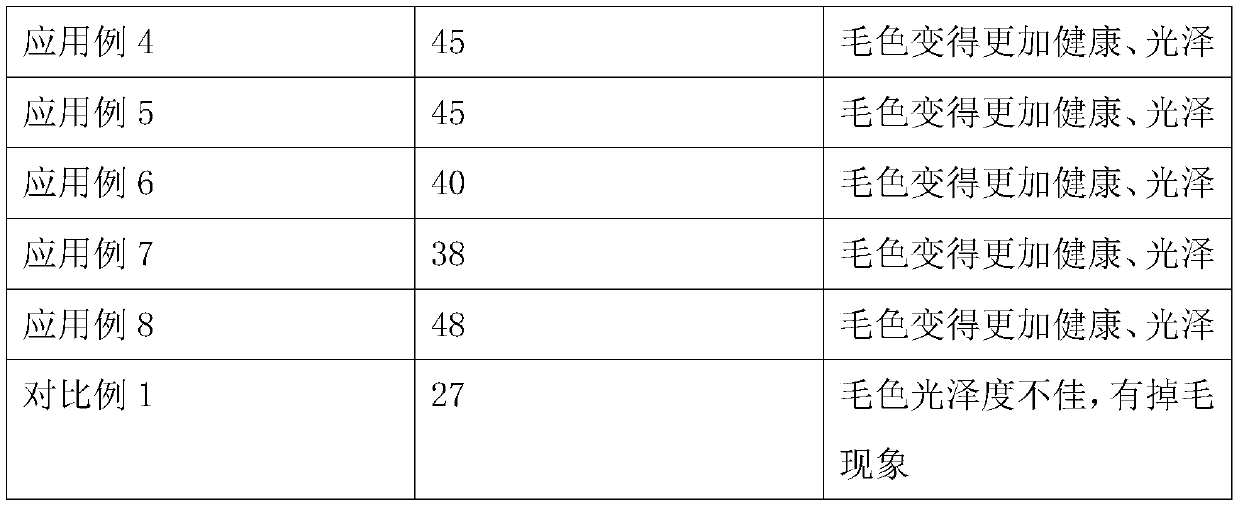

Examples

Embodiment 1

[0038] Pichia pastoris AN-PK-9K-GS115 described in this embodiment is selected and bred by the following method:

[0039] A, take Bacillus subtilis as the original gene source;

[0040] B. Obtain the target gene sequence Fpk by using overlap extension PCR technology; the overlap extension PCR technology uses primers with complementary ends to make the PCR products form overlapping chains, so that in the subsequent amplification reaction, the overlapping chains can be extended to separate the genes from different sources. The amplified fragments are overlapped and spliced together;

[0041] The conditions during the PCR amplification process are as follows: (containing 10 times buffer and Taq enzyme, dNTP and other In-Fusion kits) to obtain the target gene sequence Fpk (as shown in SEQ ID NO: 1);

[0042]Primer F: 5'-ctcctgccaagctgaagc-3',

[0043] Primer R: 5'-gatcatggaacggattc-3',

[0044] Amplification program: 95°C 2min; 95°C 30s, 56°C 30s, 72°C 1min, 45 cycles; 72°C 5...

example 2

[0055] Soak the above-mentioned feather meal in NaOH solution, solid-state enzymolysis for 3 hours under the conditions of material-water ratio 1:0.5, enzyme activity 1500U / g, temperature 65°C, and pH 9.0, to obtain an enzymolysis reaction solution. After testing, 55% total The protein is hydrolyzed into soluble protein, 46% of which is acid-soluble protein, and the content of ammonia nitrogen is 2.2%. The feather meal additive is obtained after the enzymolysis reaction solution is concentrated and dried.

example 3

[0057] Feather powder is soaked in NaOH solution, the ratio of material to water is 1:0.5, enzyme activity is 1500U / g, temperature is 65°C, pH is 9.0, Mg +2 Under the condition of 2mM solid-state enzymatic hydrolysis for 3 hours, the enzymatic hydrolysis reaction solution was obtained. After testing, 61% of the total protein was enzymatically hydrolyzed into soluble protein, 52% of which was acid-soluble protein, and the content of ammoniacal nitrogen was 2.7%. The feather meal additive is obtained after the enzymolysis reaction solution is concentrated and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com