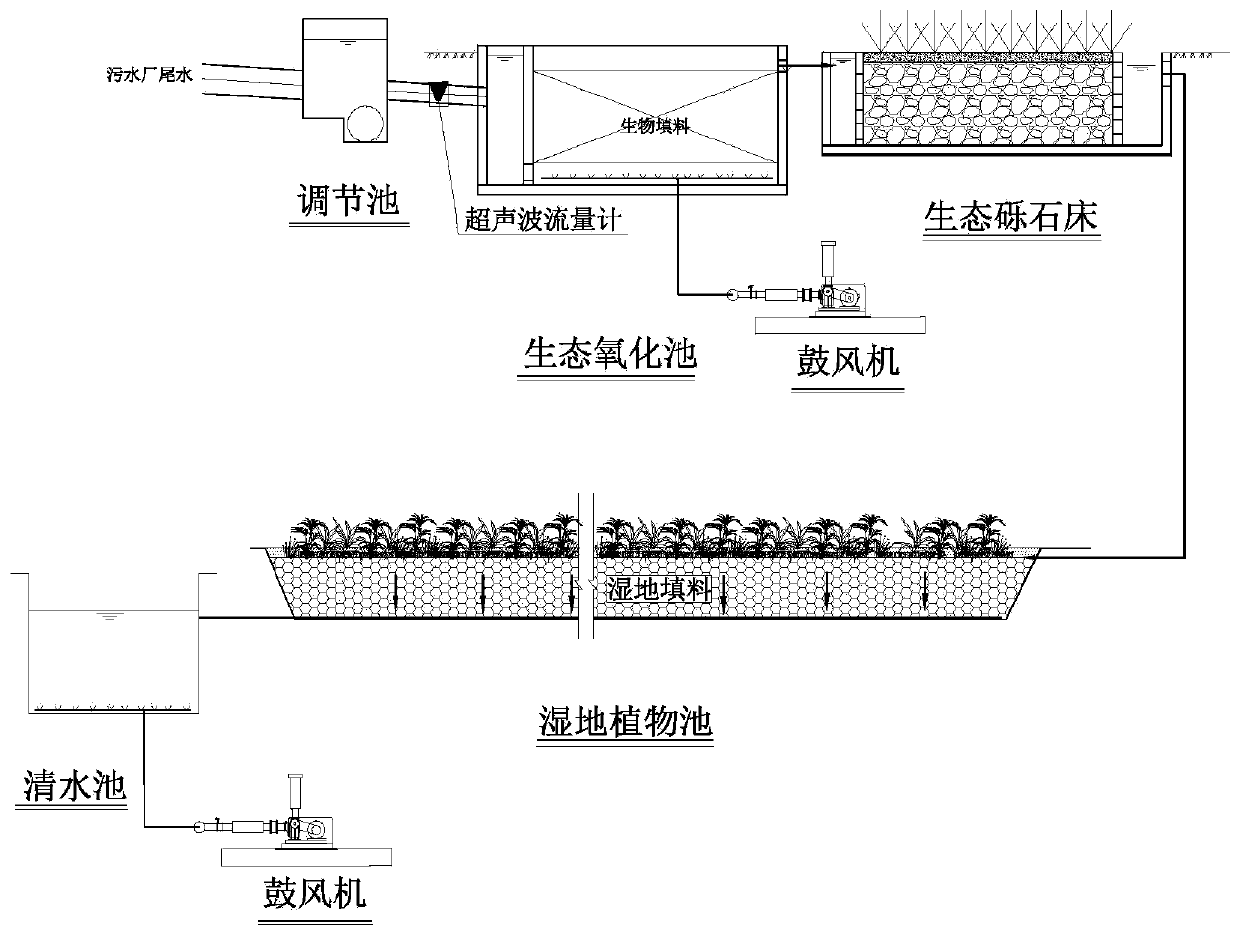

Multistage aeration oxidation pond-gravel bed-constructed wetland tail water efficient treatment system

An aeration oxidation tank and artificial wetland technology, which is applied in the field of multi-stage aeration oxidation tank-gravel bed-constructed wetland tail water efficient treatment system, can solve the problems that cannot meet the needs of modern urban water control, easily block the dissolved oxygen content of effluent, and reduce the amount of dissolved oxygen in the effluent. Water quality and water quality are sensitive and other issues, to achieve the effect of good ecological landscape effect, strong adaptability of water quality and water quantity fusion, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

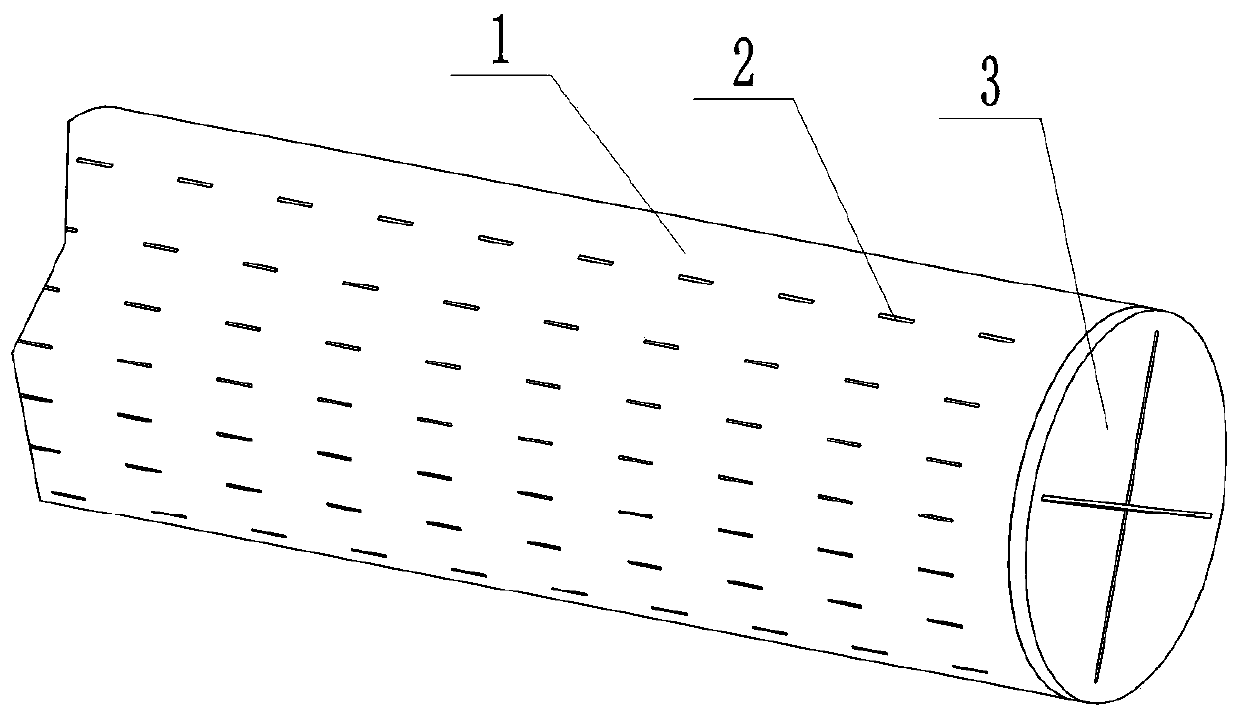

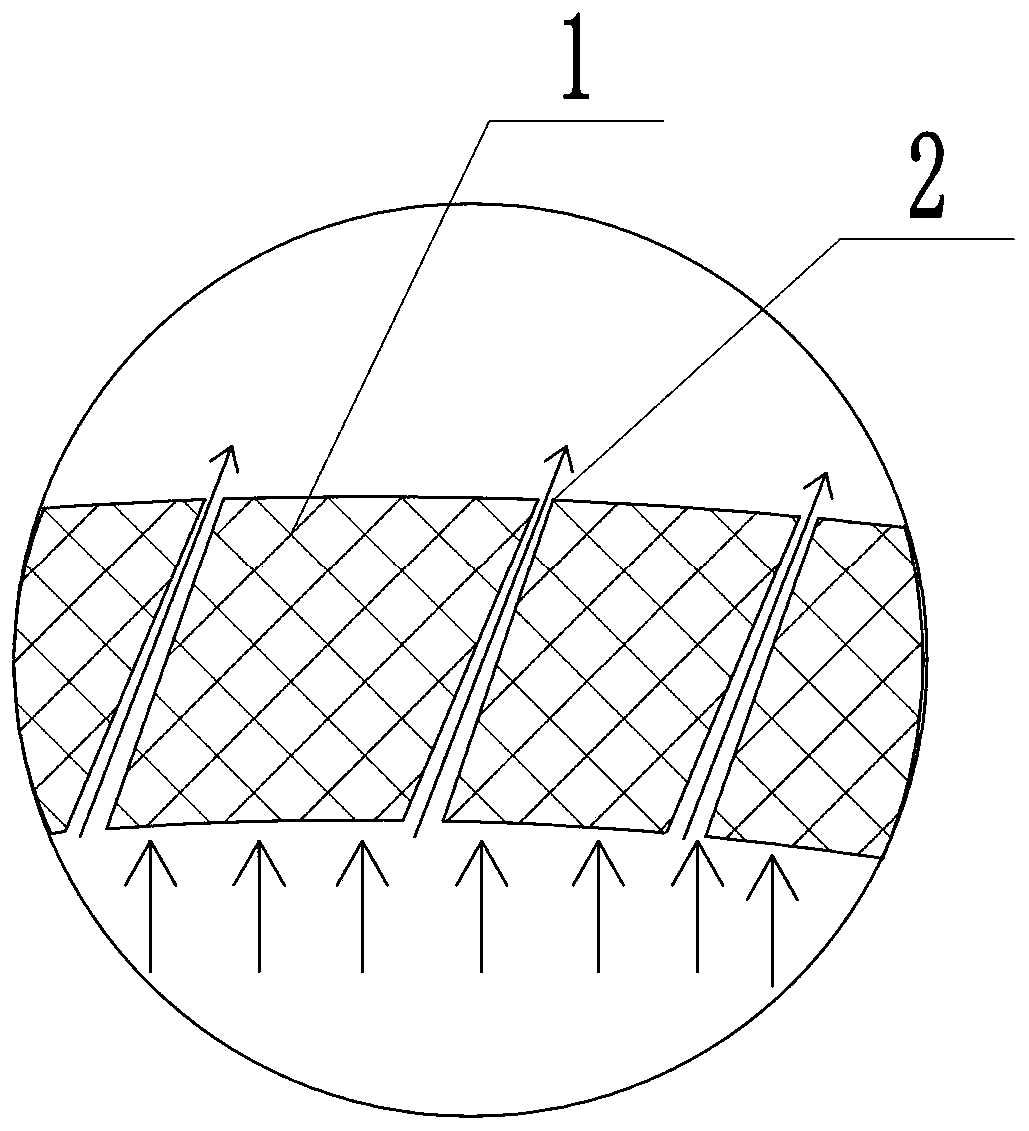

[0048] Specific embodiment: The above-mentioned multi-stage aerated ecological oxidation tank + ecological gravel bed + high-efficiency vertical flow constructed wetland integration technology is applied to the tail water deep purification project of a sewage plant in South China. The project construction land area is 43,000 m 2 , The project investment is 30 million yuan. The project is used to efficiently treat the first-class A effluent of the sewage treatment plant, and the treated water volume is 20,000 m 3 / d, and use its effluent as river ecological replenishment. Among them, the hydraulic retention time of the ecological oxidation pond is 2.5-3.0h, and the volume is 2820m 3 , effective residence time 2h, effective volume 1680m 3 , the air-water ratio is 3.0:1, and the size is 15×10×4.7m (parallel operation). Microporous nano-aeration tubes are arranged at the bottom of the pool, with an interval of 0.8 to 1.2 meters, for intermittent aeration. 6 supporting fans, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com