Reflective glass glaze ink and method for manufacturing photovoltaic glass panel by using reflective glass glaze ink

A glass glaze, photovoltaic glass technology, applied in the field of solar photovoltaic, can solve the problems of difficulty in effectively controlling the glaze filling accuracy, high graphic position accuracy, screen tension deformation, etc., and achieves low cost, high graphic position accuracy, controllable The effect of caulking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The selected reflective glass glaze ink components are as follows: glass glaze 12%, nano-colorant 10%, diluent 60%, resin 15% and additive 3%. Among them, the Tg temperature of the glass glaze is 600° C., the nano pigment is nano titanium oxide powder, the diluent is TPGDA, the resin is acrylic resin oligomer, and the additive is TPO.

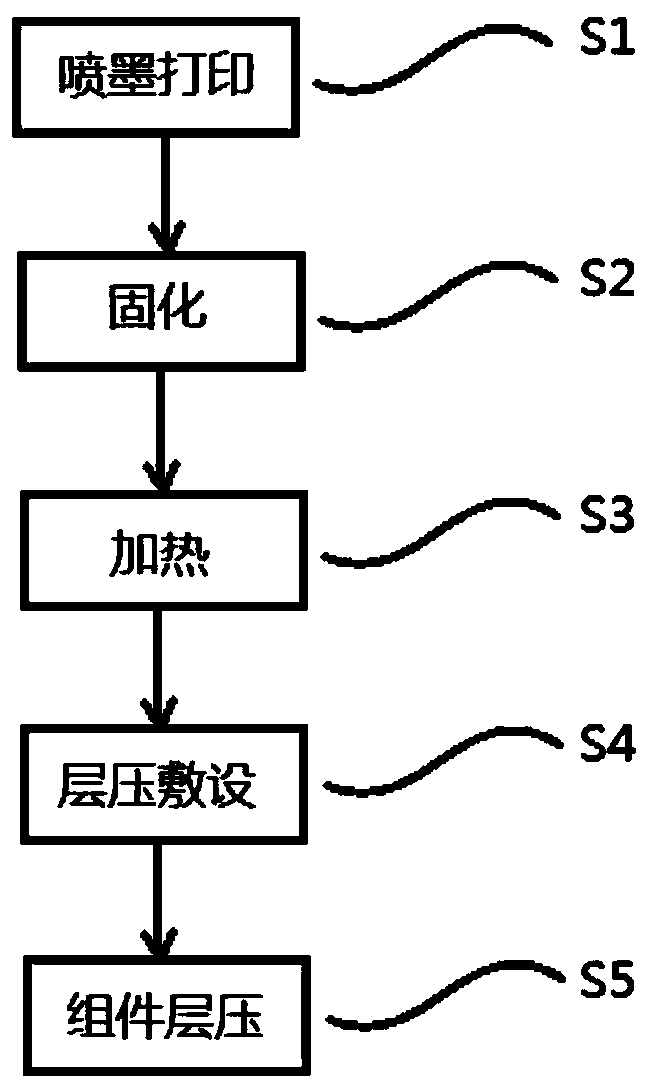

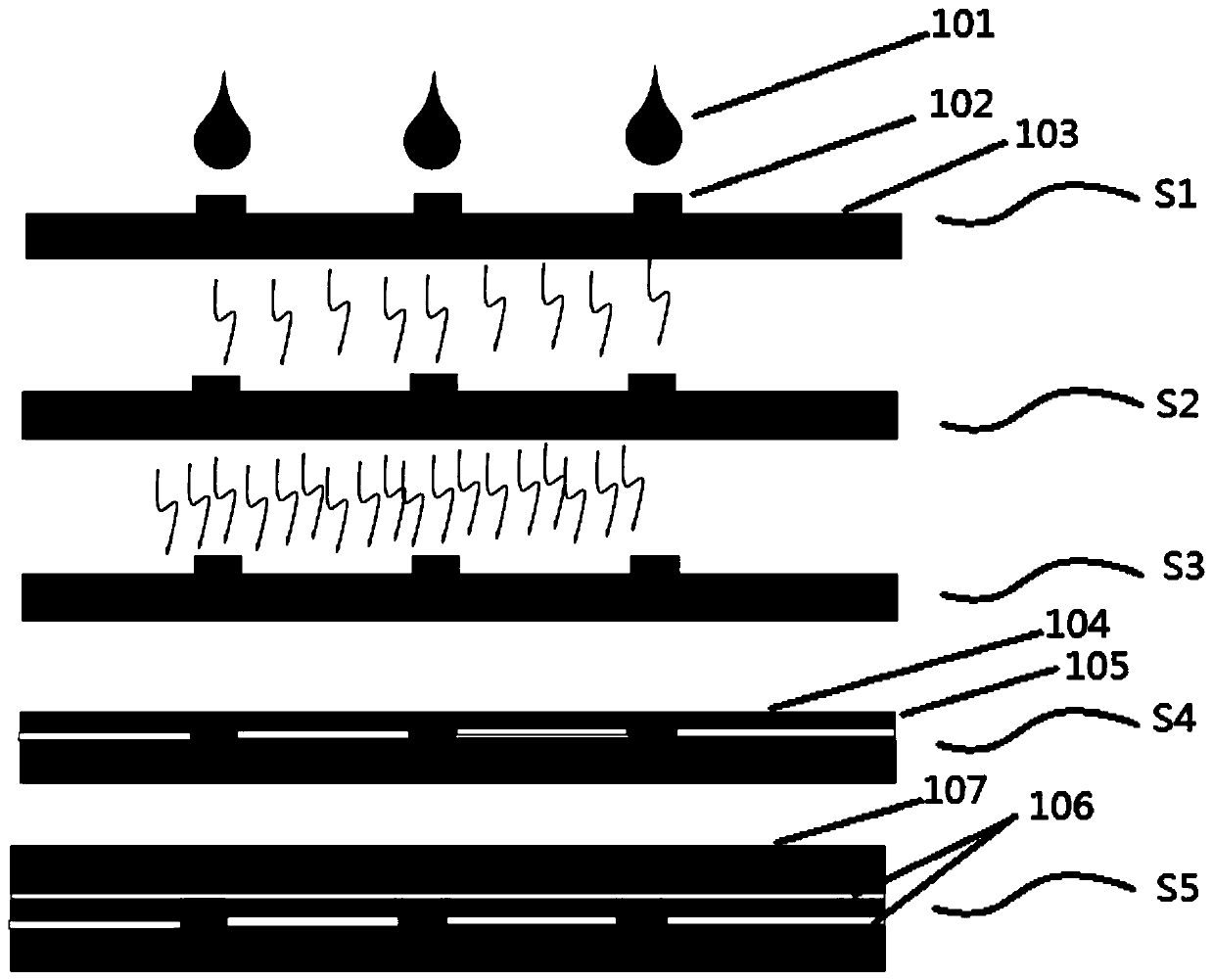

[0044] S1 inkjet printing: spray the glass glaze ink on the glass back plate according to the preset grid pattern, control the diameter of the glass glaze ink droplet (ink drop 101) to 0.1mm, and the viscosity of the ink in the spraying stage At 80cps;

[0045] S2 curing: using a UV curing method to cure the glass glaze ink sprayed in step S1;

[0046] S3 heating: sintering at 800°C for 1 minute to melt and bond the glass glaze to the glass back plate;

[0047] S4 Laminate: Laminate in the order of laminated glass backplane 103, EVA film 106, battery string 104, bus bar 105, EVA film 106, and glass panel 107; among them, the battery string is a...

Embodiment 2

[0050] The selected reflective glass glaze ink components are as follows: glass glaze 3%, nano-colorant 30%, diluent 57%, and additive 10%. Among them, the Tg temperature of the glass glaze is 450°C, the nano pigment is barium sulfate powder, the diluent is butyl carbitol, and the additives are Tego 655 dispersant and BYK333 surface tension control agent.

[0051] S1 inkjet printing: spray the glass glaze ink on the glass back plate according to the preset grid pattern, control the diameter of the glass glaze ink droplet (ink drop 101) to 0.15mm, and the viscosity of the ink in the spraying stage At 120cps;

[0052] S2 curing: the glass glaze ink sprayed by baking at less than 200°C to dry step S1;

[0053] S3 heating: sintering at 700°C for 2 minutes to melt and bond the glass glaze to the glass back plate;

[0054] S4 Laminate: Laminate in the order of laminated glass backplane 103, EVA film 106, battery string 104, bus bar 105, EVA film 106, and glass panel 107; among them, the ba...

Embodiment 3

[0057] The selected reflective glass glaze ink components are as follows: glass glaze 10%, nano-colorant 25%, resin 55% and additive 10%. Among them, the Tg temperature of the glass glaze is 450°C, the nano pigment is zirconia powder, the resin polyurethane prepolymer and the additive are IPDI.

[0058] S1 inkjet printing: spray the glass glaze ink on the glass back plate according to the preset grid pattern, control the diameter of the glass glaze ink droplet (ink drop 101) to 0.15mm, and the viscosity of the ink in the spraying stage At 180cps;

[0059] S2 curing: curing the glass glaze ink sprayed in step S1 by baking at a temperature lower than 180°C for thermal curing;

[0060] S3 heating: sintering at 600°C for 3 minutes to melt and bond the glass glaze to the glass back plate;

[0061] S4 Laminate: Laminate in the order of laminated glass backplane 103, EVA film 106, battery string 104, bus bar 105, EVA film 106, and glass panel 107; among them, the battery string is accuratel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com