A trench type Schottky device and its manufacturing method

A manufacturing method and trench-type technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as leakage, and achieve the effect of avoiding direct contact and high matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

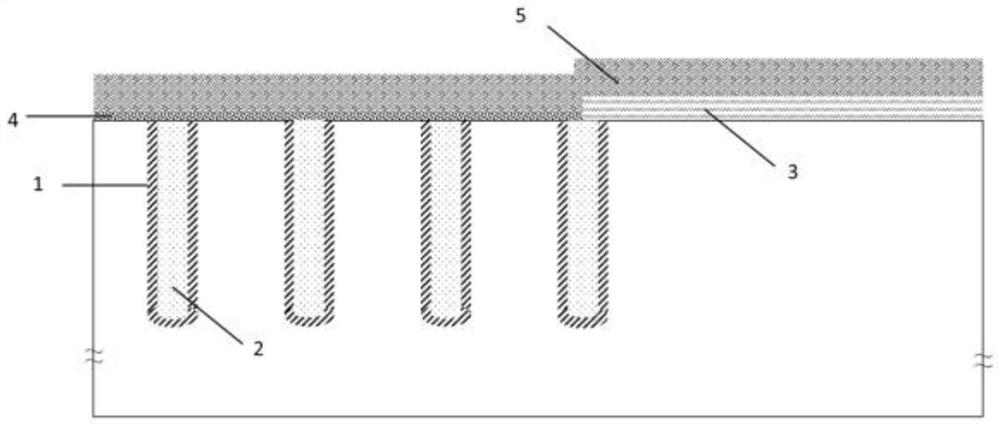

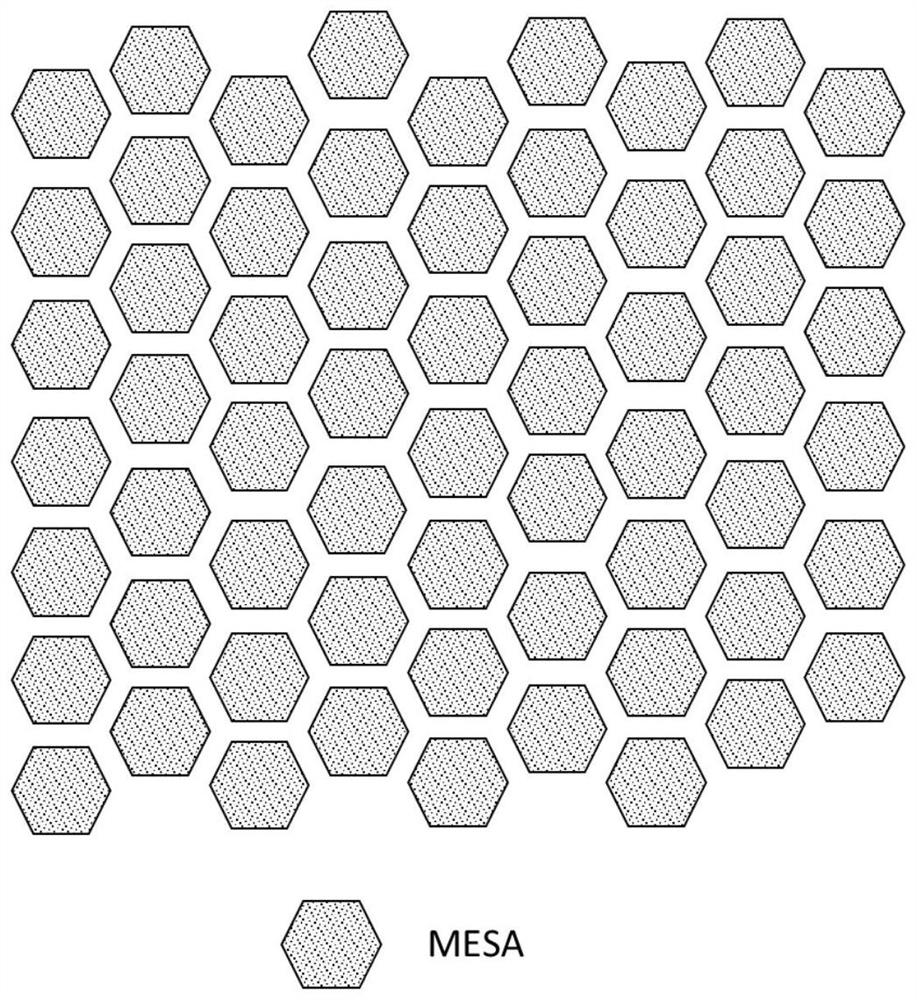

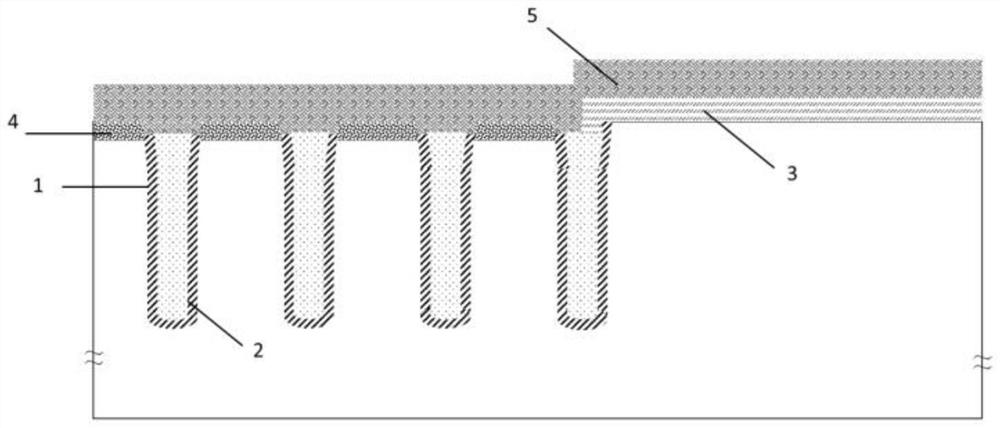

[0041] Such as figure 2 As shown, a trench-type Schottky device, its structure is a trench-type Schottky diode structure with a hexagonal cell structure, such as image 3 As shown, the topography of the trench has an oblique angle, and the metal interface of the barrier layer is lower than the interface of the contact metal layer in the vertical direction.

[0042] It is verified by experiments that the present invention adopts the hexagonal cell structure to maximize area utilization and ensure the best adaptability to subsequent technological processes. And the HDP process is added after the barrier metal is formed to ensure that the interface of the barrier metal is always 0.1um~0.3um lower than the interface of the contact metal in the vertical direction, which can avoid the leakage channel caused by the direct contact between the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com