A non-premixed hydrogen catalytic combustion heating device

A technology of catalytic combustion and heating device, applied in burner safety device, gas fuel burner, burner, etc., can solve problems such as hidden safety hazards, no anti-backfire design, etc., to ensure safety, compact structure and convenience Modular effects used in series or in parallel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

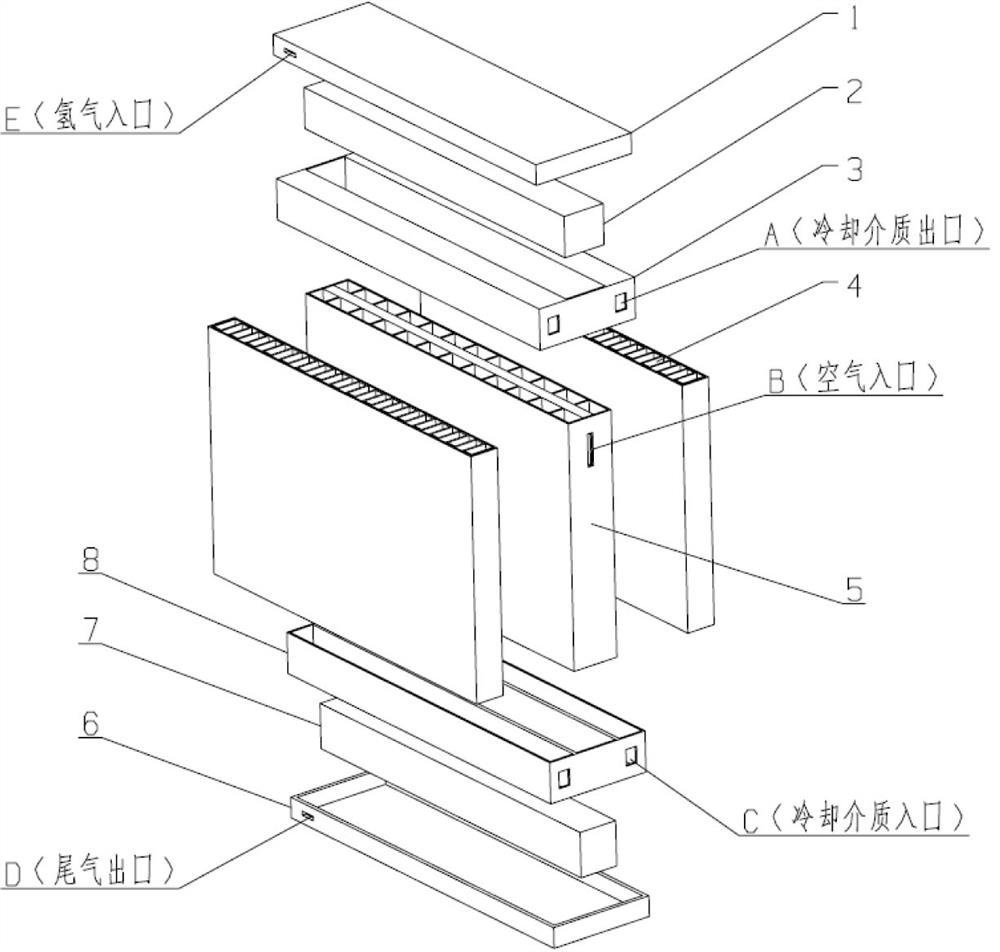

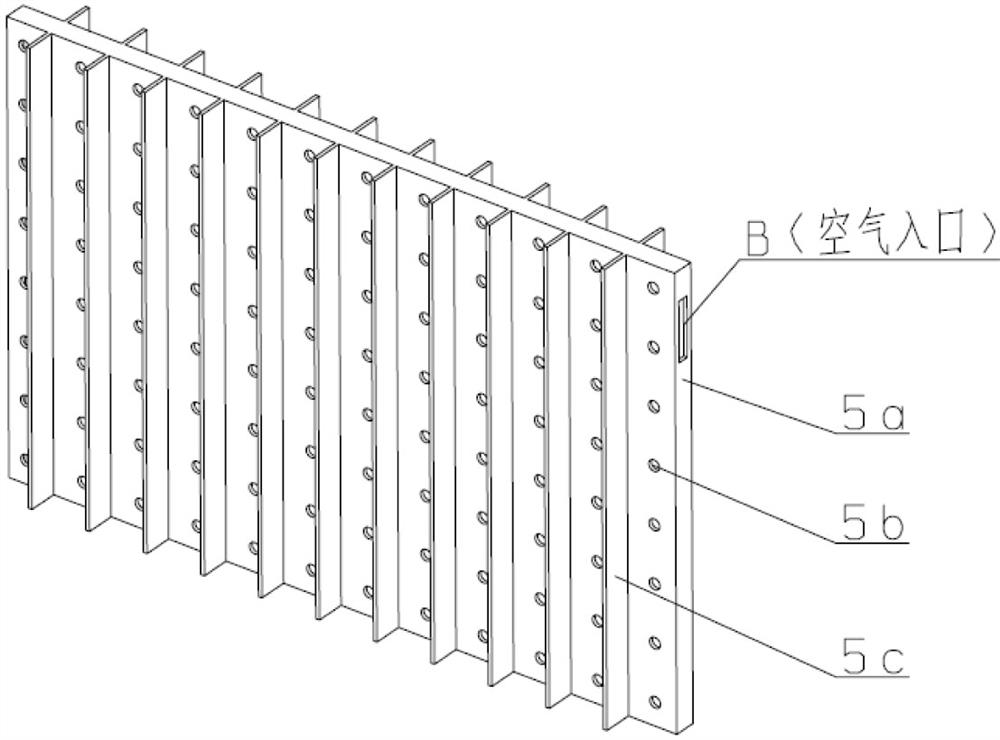

[0028]The size of the catalytic combustion chamber 5 is 100×12×60mm, the size of the air intake chamber 5a is 100×5×60mm, the uniformly distributed holes 5b have a diameter of 2mm and are uniformly arranged in 12×8; the size of the heat exchange chamber 4 is 100×8×60mm, Both the catalytic combustion chamber 5 and the heat exchange chamber 4 are made of copper-nickel alloy. The cross section of the corrugated alloy strip in the corrugated plate fire-stop core 2 is isosceles triangle, the obtuse angle of the triangle is 120°, the height is 0.2mm, and the thickness is 0.1mm; the flat alloy strip is rectangular, the thickness is 0.15mm, and the material is copper-silver-zirconium alloy. Nickel foam 7 has a size of 96×10×10mm and a pore density of 40PPI. The catalyst is selected from γ-Al 2 o 3 -Carbon nanotube (CNT) supported Pt granular catalyst.

[0029] Hydrogen and air are passed into the catalytic combustion chamber 5 respectively, the hydrogen is controlled to account for...

Embodiment 2

[0031] The size of the catalytic combustion chamber 5 is 100×8×60mm, the size of the air intake chamber 5a is 100×5×60mm, the uniformly distributed holes 5b have a diameter of 1mm and are uniformly arranged at 15×10; the size of the heat exchange chamber 4 is 100×15×60mm, Both the catalytic combustion chamber 5 and the heat exchange chamber 4 are made of copper alloy. The cross section of the corrugated alloy strip in the corrugated fire retardant core is isosceles triangle, the obtuse angle of the triangle is 120°, the height is 0.2mm, and the thickness is 0.1mm; the flat alloy strip is rectangular, the thickness is 0.15mm, and the material is copper-silver-zirconium alloy. The size of nickel foam 7 is 96×6×10mm, and the pore density is 40PPI. Catalyst selection Al 2 o 3 Make a transition layer, and then chemically deposit the wall-supported catalyst of the Pt active layer.

[0032] Hydrogen and air are respectively passed into the catalytic combustion chamber 5, and the h...

Embodiment 3

[0034] The size of the catalytic combustion chamber 5 is 150×20×100mm, the size of the air intake chamber 5a is 150×8×100mm, the uniformly distributed holes 5b have a diameter of 2mm and are uniformly arranged in 12×8; the size of the heat exchange chamber 4 is 150×8×100mm, Both the catalytic combustion chamber 5 and the heat exchange chamber 4 are made of copper alloy. The cross section of the corrugated alloy strip in the corrugated fire retardant core is isosceles triangle, the obtuse angle of the triangle is 120°, the height is 0.2mm, and the thickness is 0.1mm; the flat alloy strip is rectangular, the thickness is 0.15mm, and the material is copper-silver-zirconium alloy. Nickel foam 7 has a size of 146×18×10mm and a pore density of 40PPI. The catalyst is selected from γ-Al 2 o 3 -Carbon nanotube (CNT) supported Pt granular catalyst, hydrogen-air catalytic combustion space velocity 10000h -1 .

[0035] Hydrogen and air are passed into the catalytic combustion chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com