Ultrafiltration membrane surface modifier and modification method

A surface modifier and ultrafiltration membrane technology, which is applied in the field of ultrafiltration membranes, can solve the problems of ultrafiltration membrane pollution, etc., and achieve the effects of reducing pollution, reducing direct contact, and increasing anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

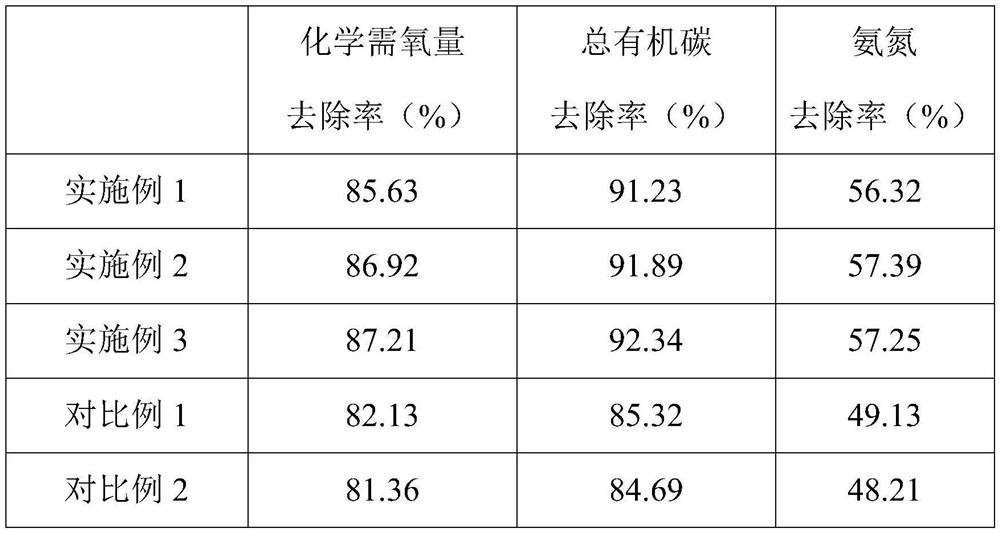

Embodiment 1

[0025] A kind of ultrafiltration membrane surface modifier, comprises following component: diatomaceous earth, yttrium sulfate, titanium dioxide; The preparation method of described ultrafiltration membrane surface modifier comprises the following steps:

[0026] S1. Dissolve 2 kg of diatomite with a mesh number of 300 mesh and 0.1 kg of titanium dioxide with a mesh number of 600 mesh in sulfuric acid solution, stir at a rate of 200 r / min for 20 hours, filter, and dry;

[0027] S2. Add the substance obtained in S1 to 5kg of yttrium sulfate solution with a concentration of 0.01mol / L, stir for 12h at a rate of 100r / min, filter, and dry;

[0028] S3. Mix the substance obtained in S2 with 0.01 kg of chlorinated paraffin and then calcinate to obtain the surface modifier, wherein the calcining specifically includes: first heating up from room temperature to 250°C at 5°C / min, and keeping the temperature for 3h; ℃ / min to cool down to 190°C, hold for 0.5h; then heat up to 350°C at 10°C...

Embodiment 2

[0033] A kind of ultrafiltration membrane surface modifier, comprises following component: diatomaceous earth, yttrium sulfate, titanium dioxide; The preparation method of described ultrafiltration membrane surface modifier comprises the following steps:

[0034] S1. Dissolve 2.2 kg of diatomite with a mesh number of 350 mesh and 0.15 kg of titanium dioxide with a mesh number of 650 mesh in sulfuric acid solution, stir at a rate of 350 r / min for 20 hours, filter, and dry;

[0035] S2. Add the substance obtained in S1 to 7kg of yttrium sulfate solution with a concentration of 0.03mol / L, stir for 15h at a rate of 200r / min, filter, and dry;

[0036] S3. Mix the substance obtained in S2 with 0.01 kg of chlorinated paraffin and then calcinate to obtain the surface modifier, wherein the calcining specifically includes: first heating up from room temperature to 255°C at 8°C / min, and keeping the temperature for 4h; ℃ / min to cool down to 195°C, keep warm for 0.8h; then raise the temper...

Embodiment 3

[0041] A kind of ultrafiltration membrane surface modifier, comprises following component: diatomaceous earth, yttrium sulfate, titanium dioxide; The preparation method of described ultrafiltration membrane surface modifier comprises the following steps:

[0042] S1. Dissolve 2.5 kg of diatomite with a mesh number of 400 mesh and 0.1 kg of titanium dioxide with a mesh number of 700 mesh in sulfuric acid solution, stir at a rate of 500 r / min for 20 hours, filter, and dry;

[0043] S2. Add the substance obtained in S1 to 8kg of yttrium sulfate solution with a concentration of 0.05mol / L, stir for 18h at a rate of 300r / min, filter, and dry;

[0044]S3. Mix the material obtained in S2 with 0.05 kg of chlorinated paraffin and then calcinate to obtain the surface modifier, wherein the calcining specifically includes: first heating up from room temperature to 260°C at 10°C / min, and keeping the temperature for 5h; ℃ / min to cool down to 200°C, hold for 1 hour; then heat up to 360°C at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com