Light-transmitting and self-luminous integrated concrete as well as preparation method and application thereof

A concrete and self-luminous technology, applied in the field of concrete materials, can solve the problems of rare concrete and other problems, and achieve the effect of simple steps, good bending resistance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

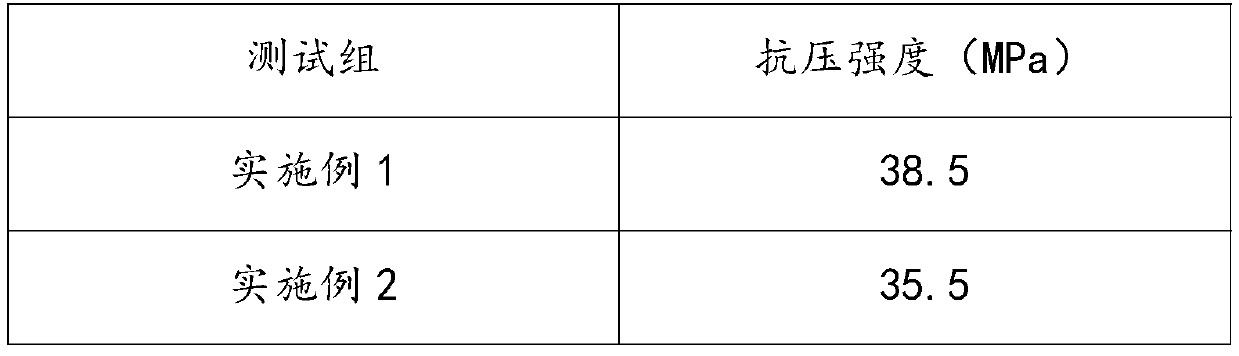

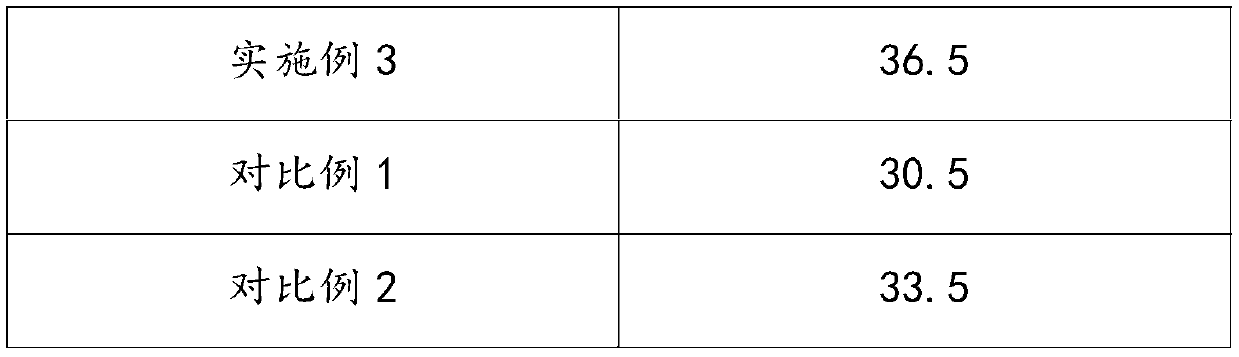

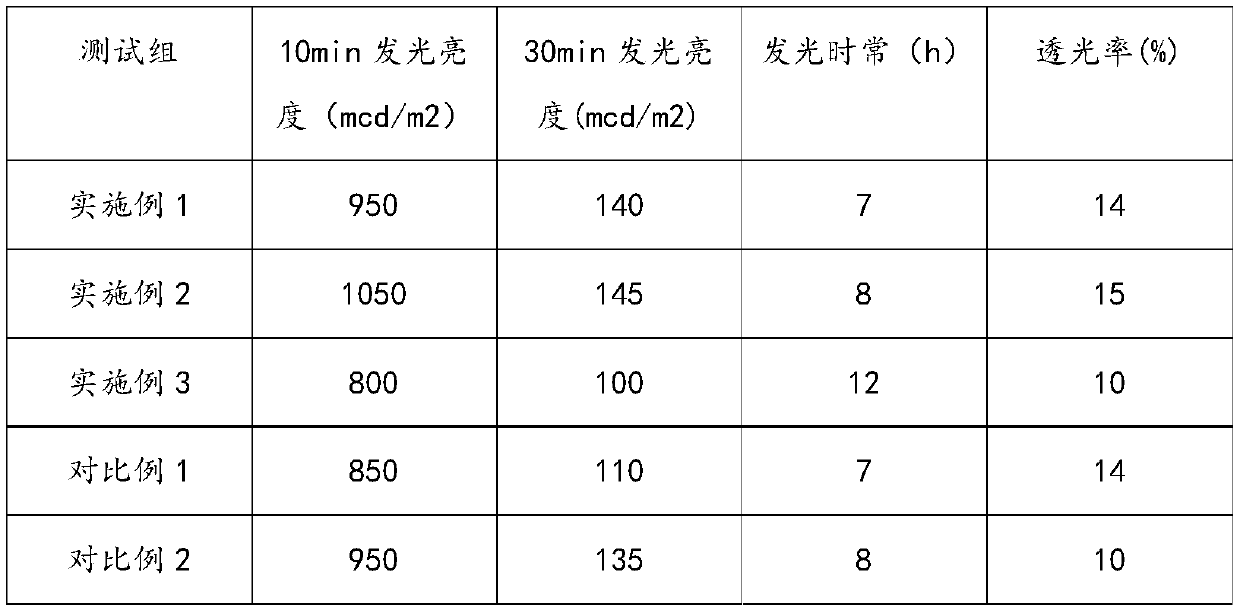

Examples

Embodiment 1

[0051] According to mass parts: 500 parts of 42.5 white Portland cement, 215 parts of coal ash, 180 parts of silica fume, 680 parts of 40-80 mesh graded quartz sand, 100 parts of luminescent stone, 30 parts of luminescent powder, and 30 parts of diatomite , 15 parts of rubber powder, 5 parts of cellulose, 3 parts of water-repellent agent, 18 parts of admixture, 20 parts of wood fiber, 20 parts of expansion agent, 5 parts of titanium dioxide, 150 parts of optical fiber, and 170 parts of water. each raw material;

[0052] Wherein, the admixture is prepared by stirring and mixing 50% polycarboxylate water reducer, 0.3% defoamer, 2% retarder, 0.06% cellulose ether water retaining agent, and the rest of water.

[0053] Then, according to the following steps, the light-transmitting and self-illuminating integrated concrete of Example 1 was prepared:

[0054] (a) Add the cement, silica fume, rubber powder, fiber, cellulose, luminous powder, diatomaceous earth, water-repellent agent,...

Embodiment 2

[0060] According to mass parts: 450 parts of 42.5 white Portland cement, 200 parts of coal ash, 175 parts of silica fume, 680 parts of 40-80 mesh graded quartz sand, 120 parts of luminescent stone, 30 parts of luminescent powder, and 40 parts of diatomite , 18 parts of rubber powder, 5 parts of cellulose, 4 parts of water-repellent agent, 18 parts of admixture, 25 parts of wood fiber, 18 parts of expansion agent, 160 parts of optical fiber, and 170 parts of water, respectively weigh appropriate amount of each raw material;

[0061] Wherein, the admixture is prepared by stirring and mixing 50% polycarboxylate water reducer, 0.3% defoamer, 2% retarder, 0.06% cellulose ether water retaining agent, and the rest of water.

[0062] Then, according to the method of Example 1, the light-transmitting and self-illuminating integrated concrete of Example 2 was obtained.

Embodiment 3

[0064] According to mass parts: 500 parts of 42.5 white Portland cement, 215 parts of coal ash, 180 parts of silica fume, 680 parts of 40-80 mesh graded quartz sand, 30 parts of luminescent stone, 100 parts of luminescent powder, and 30 parts of diatomite , 15 parts of rubber powder, 5 parts of cellulose, 3 parts of water-repellent agent, 18 parts of admixture, 20 parts of wood fiber, 20 parts of expansion agent, 5 parts of titanium dioxide, 120 parts of optical fiber, and 170 parts of water. each raw material;

[0065] Then, according to the method of Example 1, the concrete material of Example 1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com