A kind of b-al-ti series composite phase ceramics and its low-temperature densification sintering preparation method

A composite ceramic, b-al-ti technology, applied in the field of boride ceramics, can solve the problems of sintering and preparation of boride ceramics, the decrease of the strength of sintered samples, and the limitation of application prospects, etc., to achieve low-temperature densification and reduce sintering Difficulty, the effect of lowering the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

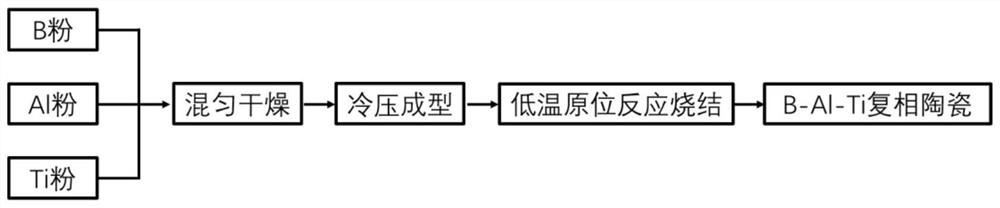

[0029] like figure 1 Shown is the process flow diagram of the present invention for preparing B-Al-Ti composite phase ceramics, and its low-temperature densification and sintering preparation method comprises the following steps:

[0030] (a) Mix B powder, Al powder and Ti powder evenly, wherein the molar ratio x:y of Al powder and Ti powder is (1-9):1, and the molar weight of B powder is 12x+2y;

[0031] (b) prefabricating the green body by cold pressing the mixture in the step (a);

[0032] (c) performing plasma activation sintering on the green body prepared in step (b), and obtaining B-Al-Ti multiphase ceramics under the sintering condition of 1460-1600°C.

[0033] In powder metallurgy engineering, the particle size of the raw material powder will greatly affect the structure and performance of the final sintered product. The smaller the particle size of the raw material powder, the greater its surface driving force and the higher the activation energy provided during th...

Embodiment 1

[0045] To prepare high-performance B-Al-Ti composite phase ceramics, the preparation process is followed by powder weighing, powder mixing, cold pressing into blanks and in-situ reaction sintering, and the B-Al-Ti composite phase ceramics are obtained after sintering. The specific steps are as follows:

[0046] 1. Weighing and mixing

[0047] Take by weighing 99% purity, 10.81g of B powder with a particle size of 0.5-1μm, 2.21g of Al powder with a particle size of 1-3μm and 0.44g of Ti powder with a particle size of 2-5μm (according to B-Al- AlB in Ti-based composite ceramics 12 with TiB 2 The molar ratio is 9:1), and the mixed powder is freeze-dried for 24 hours by freeze-drying equipment, and then mixed uniformly by using a low-energy ball mill for 6 hours to obtain the mixed powder.

[0048] 2. Cold forming

[0049] Take 3g of the mixed powder obtained in step 1 and put it into a 304L mould, and use a tablet press to perform cold compression molding (pressure 30MPa), an...

Embodiment 2

[0060] To prepare high-performance B-Al-Ti composite phase ceramics, the preparation process is followed by powder weighing, powder mixing, cold pressing into billets and in-situ reaction sintering. After the sintering is completed, the B-Al-Ti composite phase ceramics are obtained. The specific steps are as follows:

[0061] 1. Weighing and mixing

[0062] Take by weighing 99% purity, 10.81g of B powder with a particle size of 0.5-1μm, 1.89g of Al powder with a particle size of 1-3μm and 3.35g of Ti powder with a particle size of 2-5μm (according to B-Al- AlB in Ti-based composite ceramics 12 with TiB 2 The molar ratio is 1:1), and the mixed powder is freeze-dried for 24 hours by freeze-drying equipment, and then mixed uniformly by using a low-energy ball mill for 6 hours to obtain a mixed powder.

[0063] 2. Cold forming

[0064] Take 3g of the mixed powder obtained in step 1 and put it into a 304L mould, and use a tablet press to perform cold compression molding (press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com