Two-component elastic coating and preparation method thereof

An elastic coating, two-component technology, applied in the direction of fireproof coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problem that elastic coatings cannot have both elasticity, stain resistance, and scratch resistance , to achieve the effects of reducing pollution and harm to the human body, excellent flexibility, broad application prospects and development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

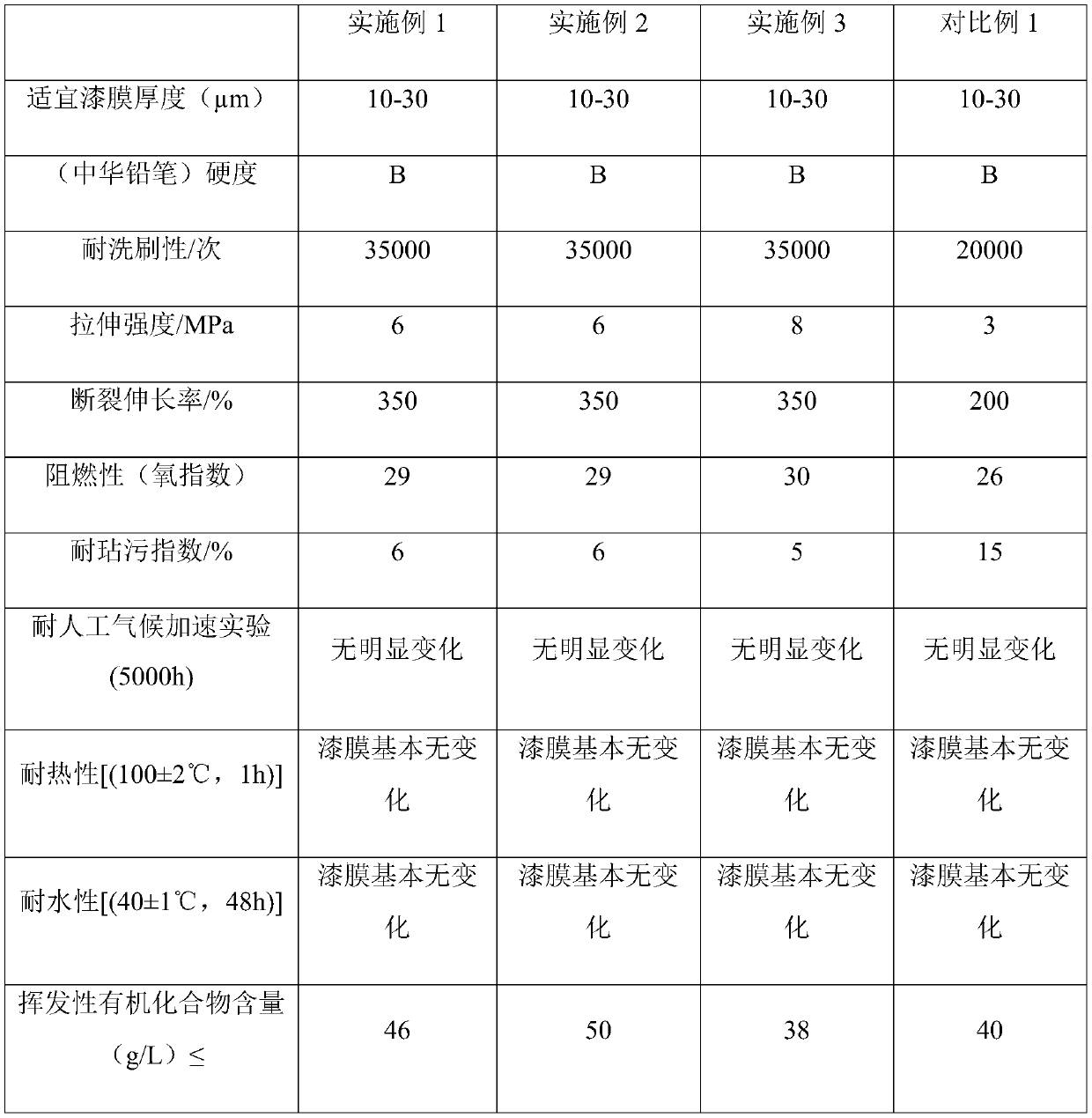

Examples

Embodiment 1

[0059] The embodiment of the present invention provides a two-component elastic coating, the A component includes the following raw material components in parts by mass: 60 g of aqueous polyurethane dispersion, 2 g of lignocellulose / expandable graphite composite material, 1 g of hand feeling aid, Organic silicone powder 9g, nano silver 0.2g, negative ion powder 0.8g, flame retardant 3g, fumed silica 0.2g, pH regulator 0.5g, substrate wetting agent 1g, pigment 10g, defoamer 3g, dispersion Agent 5g, film-forming aid 7g, thickener 0.6g and deionized water 30g;

[0060] The B component includes the following raw material components in mass percentage: 25g of water-based isocyanate curing agent and 10g of co-solvent;

[0061] The mass ratio of the A component and the B component is 5:1.

[0062] Wherein, the mass ratio of the aqueous polyurethane dispersion is Crysol 6110 and Crysol 6512 of 1.2:1; the hand feeling aid is Yuanhe Acure D 820 polyurethane elastic powder; the organosi...

Embodiment 2

[0074] The embodiment of the present invention provides a two-component elastic coating, the A component includes the following raw material components in parts by mass: 65g of aqueous polyurethane dispersion, 2.5g of lignocellulose / expandable graphite composite material, and 5g of hand feeling aid , organic silicone powder 10g, nano silver 0.05g, negative ion powder 1g, flame retardant 6g, fumed silica 0.6g, pH regulator 0.3g, substrate wetting agent 2g, pigment 8g, defoamer 2.5g, Dispersant 8g, film-forming aid 5g, thickener 0.2g and deionized water 25g;

[0075] The B component includes the following raw material components in mass percentage: 20g of water-based isocyanate curing agent and 15g of co-solvent;

[0076] The mass ratio of the A component and the B component is 7:1.

[0077] The trade mark of above-mentioned each component is identical with embodiment 1, and difference is: described aqueous polyurethane dispersion mass ratio is the Crysol 6110 of 1:1 and the Cr...

Embodiment 3

[0084] The embodiment of the present invention provides a two-component elastic coating. The A component includes the following raw material components in parts by mass: 70 g of aqueous polyurethane dispersion, 1.5 g of lignocellulose / expandable graphite composite material, and 8 g of hand feeling aid , organic silicone powder 8g, nano silver 0.5g, negative ion powder 0.5g, flame retardant 4g, fumed silica 1g, pH regulator 0.4g, substrate wetting agent 3g, pigment 5g, defoamer 2g, dispersion Agent 10g, film-forming aid 3g, thickener 0.8g and deionized water 20g;

[0085] The B component includes the following raw material components in mass percentage: 23g of water-based isocyanate curing agent and 13g of co-solvent;

[0086] The mass ratio of the A component and the B component is 6:1.

[0087] The trade mark of above-mentioned each component is identical with embodiment 1, and difference is: described aqueous polyurethane dispersion mass ratio is the Crysol 6110 of 0.8:1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com