Method for improving performance of mold material for automobile part production

A technology for auto parts and mold materials, which is applied in the field of improving the performance of mold materials used in the production of auto parts, can solve the problems affecting the quality of automobile assembly, long material processing cycle, and high processing costs, and achieves improved performance and aesthetics. Friction coefficient, the effect of speeding up the filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

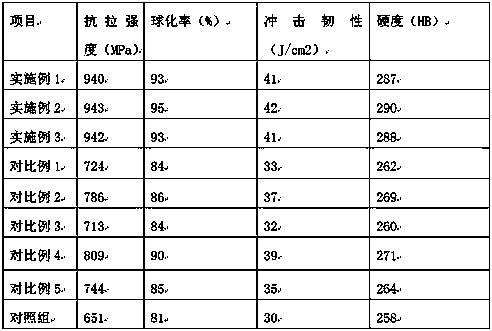

Examples

Embodiment 1

[0020] A method for improving the performance of mold materials used in the production of auto parts. The prepared nodularizing agent is added after the cast iron is smelted, and the nodularizing agent is treated by spheroidizing reaction. Include the following steps:

[0021] (1) Weigh 20 grams of silicon nitride and grind for 2 hours, add 2.7 grams of nano-titanium dioxide and mix evenly, then in an argon atmosphere, heat up to 900 ° C, calcine and oxidize for 1 hour, naturally cool to room temperature and place in the prepared acid Soak in the liquid for 4 hours, heat the oil bath to 88°C under continuous stirring, add 1.3 g of sodium hydroxide, stop stirring, age for 8 hours, naturally cool down to 20°C, use a high-speed centrifuge to separate the solid precipitate, and use ethanol Washed until neutral, placed in a drying oven at 90°C for 7 hours to obtain Si3N4 / TiO2 composite material;

[0022] (2) Weigh 7.5 grams of cerium oxide and soak it in a 60°C ethylene glycol aq...

Embodiment 2

[0031] A method for improving the performance of mold materials used in the production of auto parts. The prepared nodularizing agent is added after the cast iron is smelted, and the nodularizing agent is treated by spheroidizing reaction. Include the following steps:

[0032] (1) Weigh 21 grams of silicon nitride and grind for 2.5 hours, add 2.75 grams of nano-titanium dioxide and mix evenly, then in an argon atmosphere, heat up to 910 ° C, calcine and oxidize for 1.5 hours, naturally cool to room temperature and place in the prepared acid Soak in the liquid for 4.5 hours, heat the oil bath to 89°C under continuous stirring, add 1.45 grams of sodium hydroxide, stop stirring, age for 9 hours, naturally cool down to 22°C, use a high-speed centrifuge to separate the solid precipitate, and use ethanol Washed to neutrality, and dried in a drying oven at 95°C for 7.5 hours to obtain a Si3N4 / TiO2 composite material;

[0033] (2) Weigh 7.8 grams of cerium oxide and soak it in a 62°...

Embodiment 3

[0042] A method for improving the performance of the mold material used in the production of auto parts. After the cast iron is smelted, the prepared nodulizer is added, the nodulizer is processed, the slag is removed, and then poured and molded, and processed into a mold. The preparation process of the nodulizer Include the following steps:

[0043] (1) Weigh 22 grams of silicon nitride and grind for 3 hours, add 2.8 grams of nano-titanium dioxide and mix evenly, then heat up to 920°C in an argon atmosphere, calcine and oxidize for 2 hours, cool naturally to room temperature and place in the prepared acid Soak in the liquid for 5 hours, heat up to 90°C in an oil bath with continuous stirring, add 1.6 grams of sodium hydroxide, stop stirring, age for 10 hours, naturally cool down to 25°C, use a high-speed centrifuge to separate the solid precipitate, use ethanol Wash until neutral, and dry in a drying oven at 100°C for 8 hours to obtain a Si3N4 / TiO2 composite material;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com