Production technology for easy-to-disperse polypropylene fiber

A polypropylene fiber and production process technology, applied in the direction of single-component polyolefin rayon, fiber type, fiber treatment, etc., can solve the problems of complicated preparation steps and high requirements for fiber storage environment, and achieves uncomplicated process and dispersion. The effect of good performance and low modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

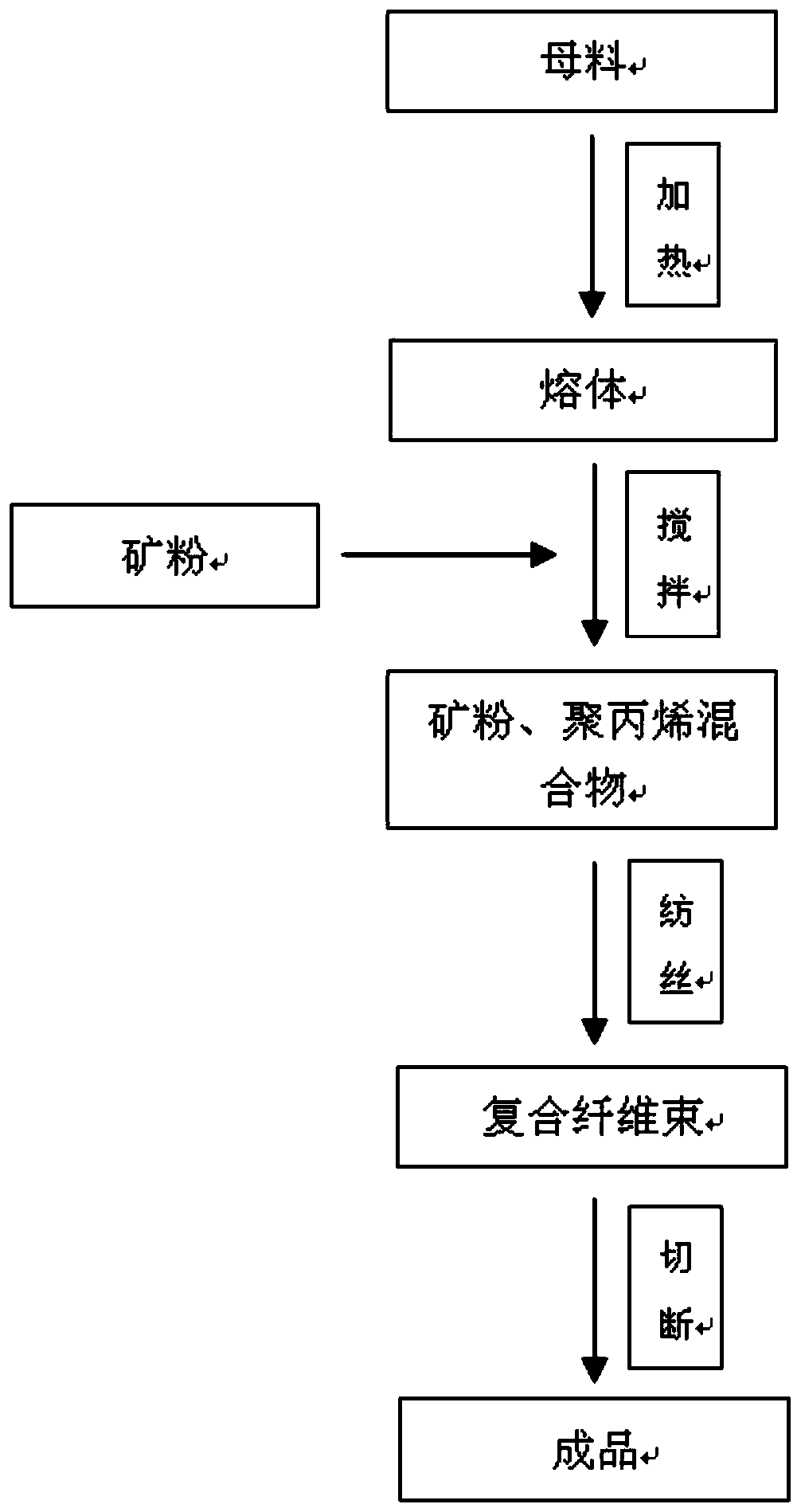

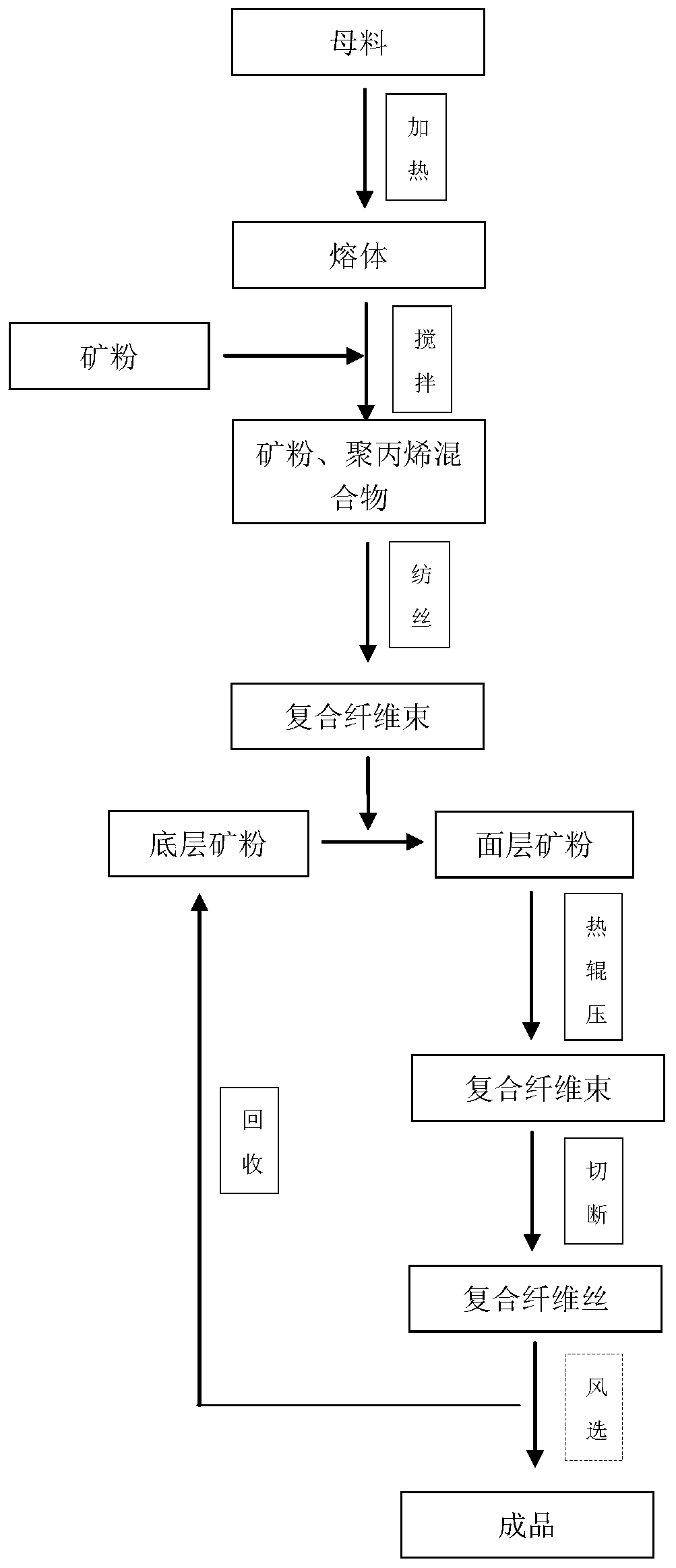

[0026] As shown in 1, the sieved and dried mineral powder particles Fe 4 o 3 Add to the molten polypropylene, and stir to make it evenly mixed. After this process is over, the melted body is then processed through spinning, cutting and other processes to obtain finished modified fibers.

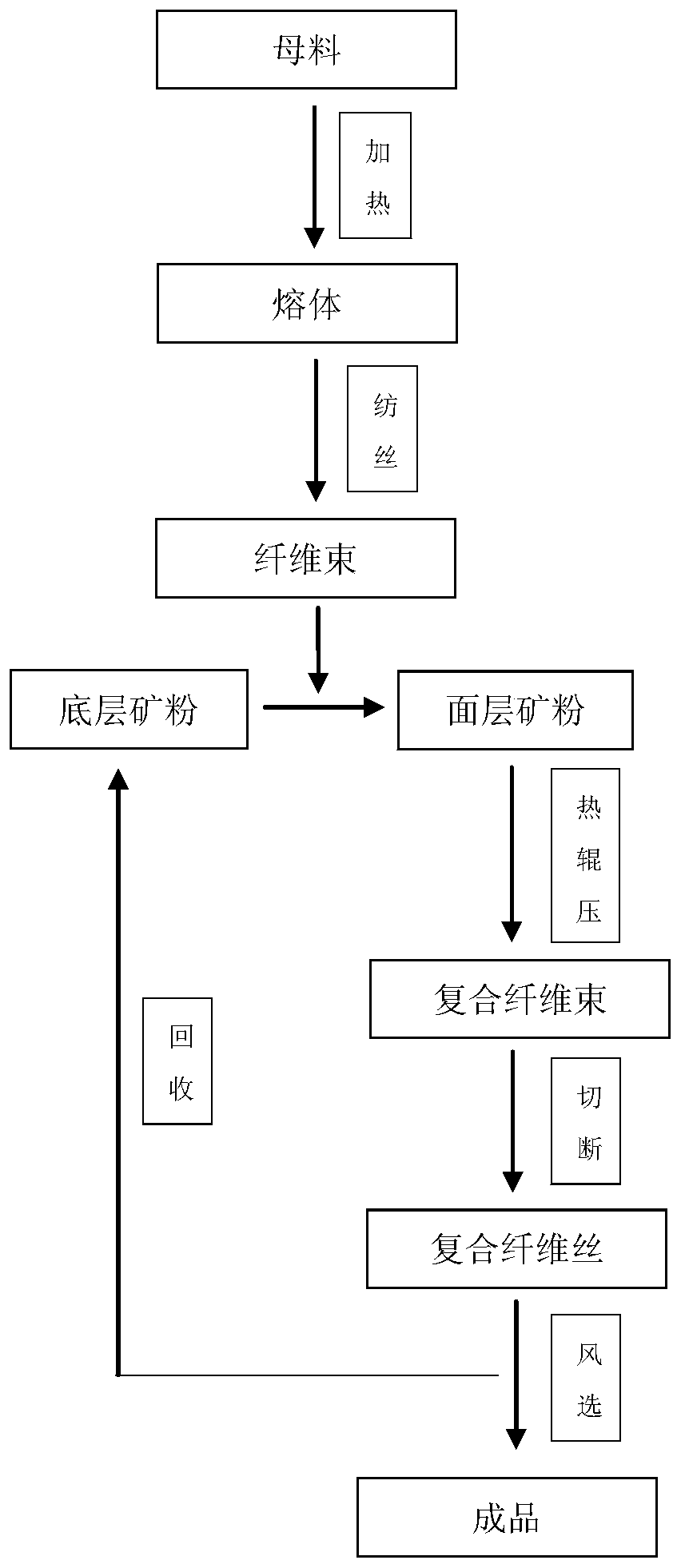

[0027] Such as figure 2 As shown, the fiber bundle made after the masterbatch is melted and spun will be added to the filler of the hot roller press through the conveying mechanism. Mineral powder particle stone mineral powder will be evenly spread on the conveying mechanism by the filler to form the bottom layer of mineral powder, and then the polypropylene fiber bundles will be spread on the bottom layer of mineral powder through the fiber filler. In order to make the fiber fully wrapped by the mineral powder particles, the surface layer of mineral powder should be evenly spread on the surface. The fiber and mineral powder are jointly sent to the hot rolling process. In this process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com