Special-shaped separated heat pipe waste heat recovery and evaporation device for passive ORC system

A separate heat pipe and waste heat recovery technology, applied in the field of expansion machine work, can solve the problems of discontinuity, the compactness of the gravity-driven power circulation system, and the large fluctuation of the output shaft power, etc., to achieve simple layout, waste heat recovery and heat. Efficient transfer avoidance, less parts effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

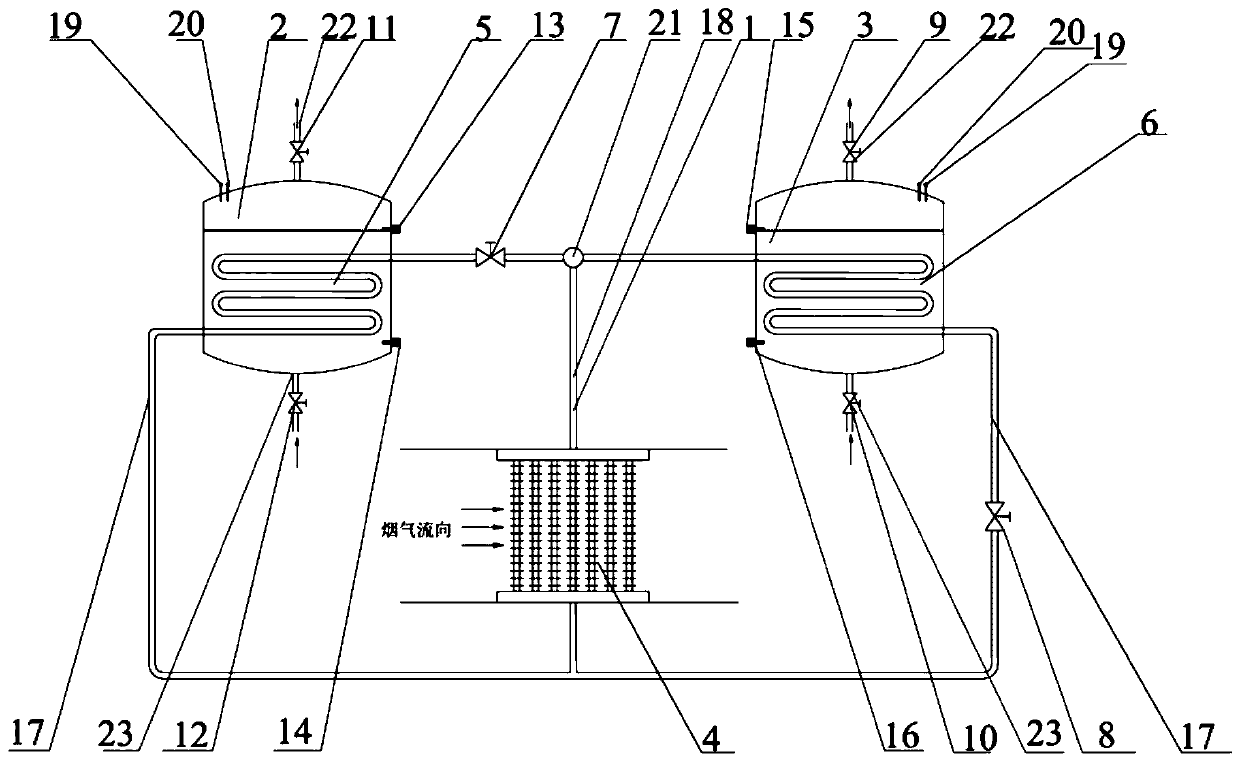

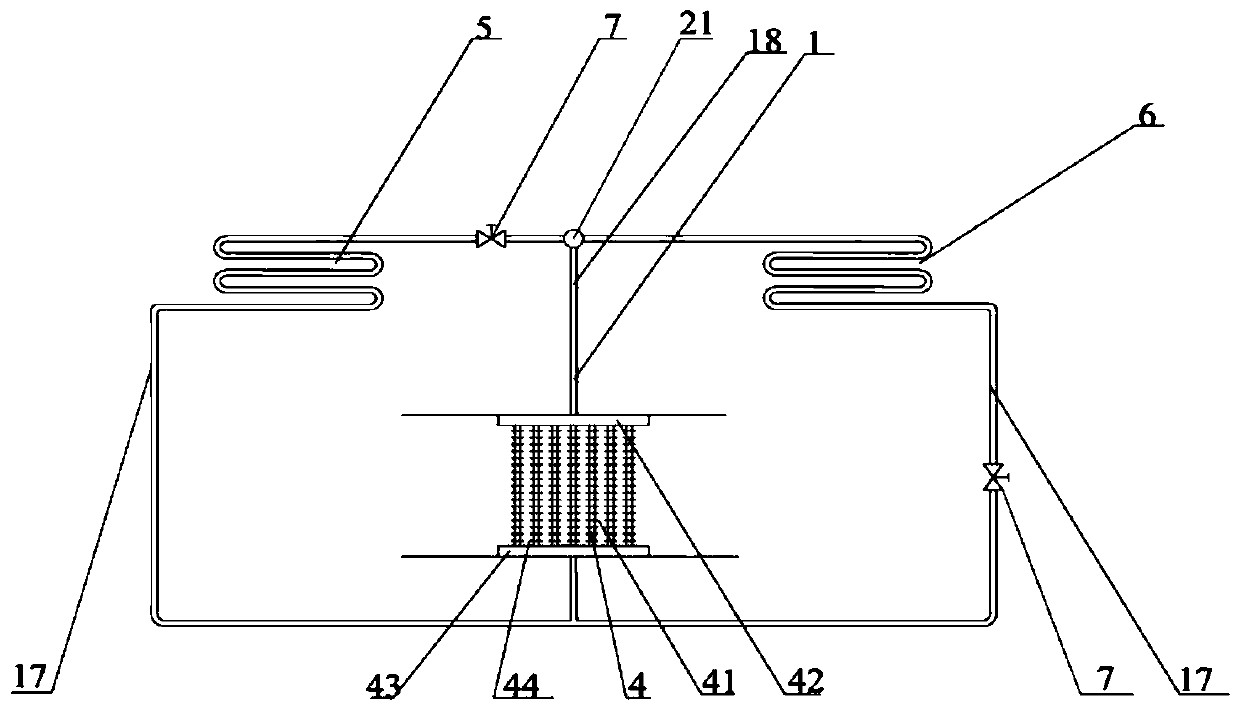

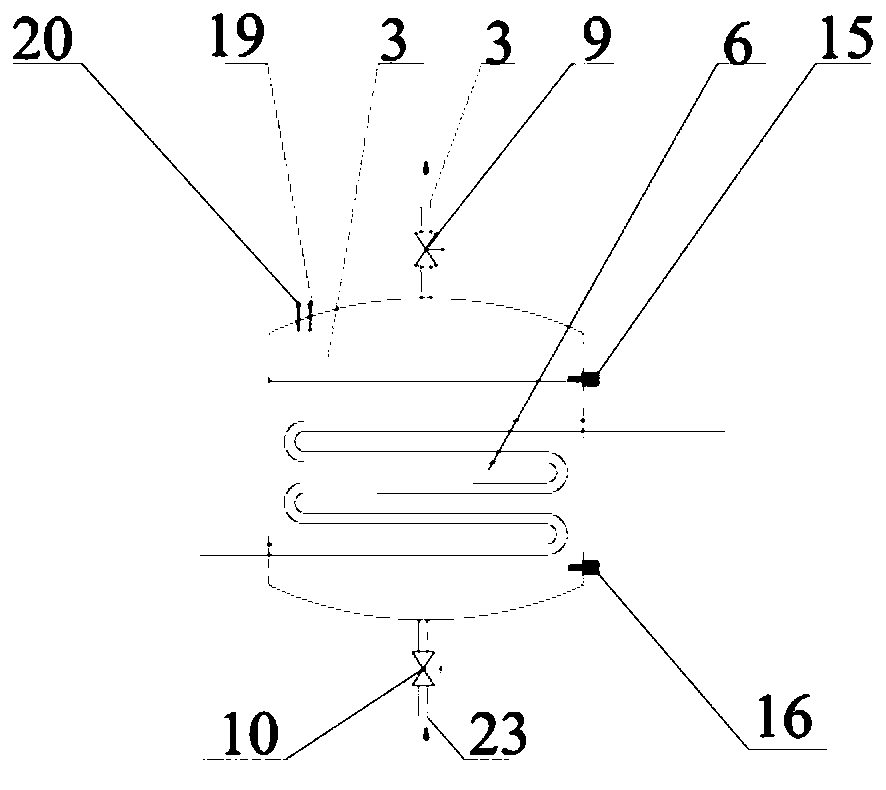

[0041] specific implementation plan

[0042] Such as Figure 1-5 As shown, a special-shaped separated heat pipe waste heat recovery evaporation device for passive ORC system is composed of double cold section special-shaped separated heat pipe 1, energy storage closed tank A2, energy storage closed tank B3, finned elliptical heat pipe evaporation section Tube bundle 4, heat pipe cooling section coil A5, heat pipe cooling section coil B6, mass flow regulating valve 7, resistance regulating valve 8, organic working medium steam outlet valve-9, organic working medium liquid inlet valve-10, organic working medium steam Outlet valve two 11, organic working fluid inlet valve two 12, high liquid level sensor one 13, low liquid level sensor one 14, high liquid level sensor two 15, low liquid level sensor two 16, liquid descending pipe 17, steam ascending pipe 18. Pressure gauge 19, thermometer 20, steam riser branch pipe 21, organic working medium steam outlet pipeline 22 and organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com