Ultrasonic scalpel system based on frequency and power tracking and control method thereof

A power tracking, scalpel technology, applied in surgery, medical science and other directions, can solve the problems of low adjustment accuracy, large overshoot, and insufficient adjustment speed, and achieves strong environmental adaptability, small system overshoot, The effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

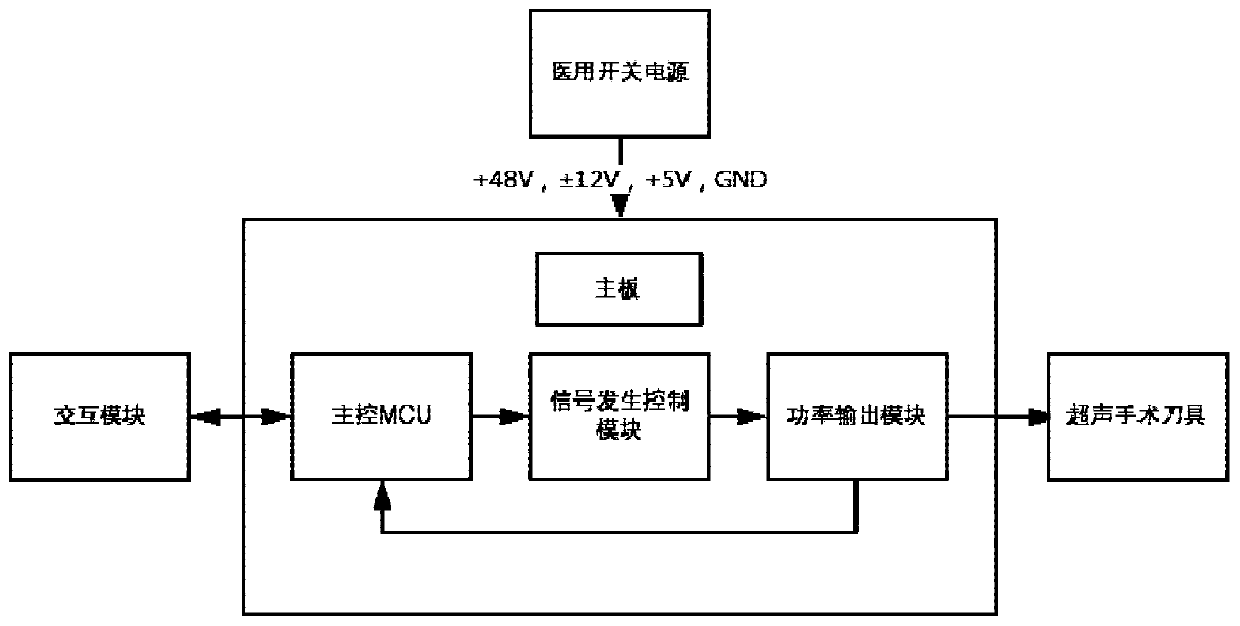

[0055] Such as figure 1 As shown, an ultrasonic scalpel system based on frequency and power tracking, including:

[0056] The signal generation control module is used to generate two complementary PWM signals with high precision frequency by receiving instructions from the main control MCU, reduce the duty cycle of the PWM signal according to the target frequency, and then amplify the power of the signal to drive the push-pull circuit Alternate conduction, make the DC signal push-pull conduction, and transmit the signal to the power drive isolation module through the high-frequency transformer;

[0057] The power output isolation module is used to make the transducer resonate within the working frequency range; simultaneously collect the amplitude and phase of the current and voltage, and transmit them to the main control MCU after processing;

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com