Preparation method of porous nano-hydroxyapatite sustained-release gel

A technology of nano-hydroxyapatite and hydroxyapatite, which is applied in the field of materials, can solve the problems of reducing the biological activity and toxicity of porous hydroxyapatite, and achieve the effects of enhancing suspension stability, accelerating metabolism time, and good drug release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

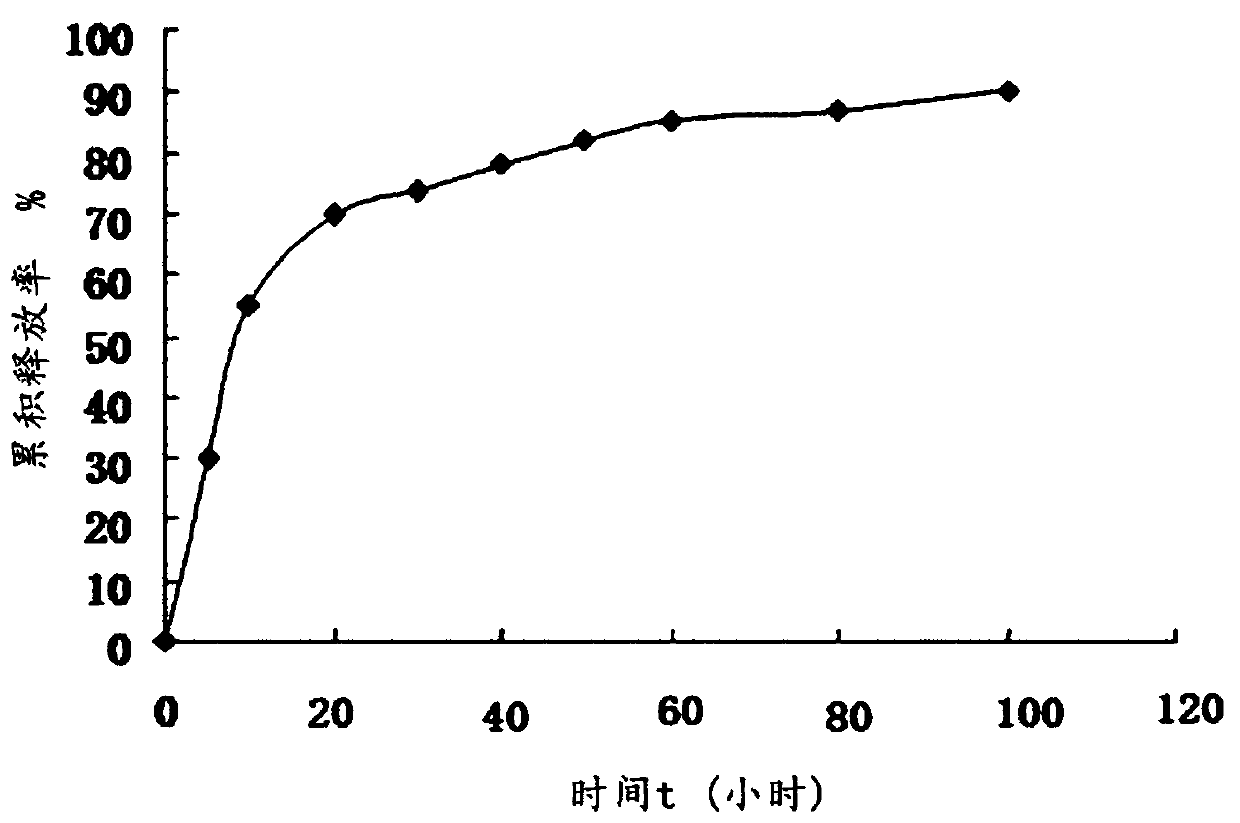

Embodiment 1

[0028] A method for preparing a porous nano-hydroxyapatite sustained-release gel of the present embodiment, the method comprises the following steps:

[0029] Step 1: adding nano-hydroxyapatite powder into water to prepare a hydroxyapatite slurry with a content of 10-40% (w / v);

[0030] Step 2: Mix the hydroxyapatite slurry, the pore-forming agent and the oleic acid in proportion, wherein the weight ratio of the hydroxyapatite slurry to the pore-forming agent is 80:20. Put it in a ball mill for 6-24 hours, and get a uniform suspension after ball milling; the pore-forming agent is carbon powder.

[0031] Step 3: adding the organic compounding agent to the suspension for mixing in proportion, and then putting it into a water bath at 80° C. for stirring and dissolving; the organic compounding agent is a combination of gelatin, gum arabic, chitosan and sodium alginate. The stirring speed of the water bath was 600r / min, and the dissolution time was 5h.

[0032] Step 4: spray-dryi...

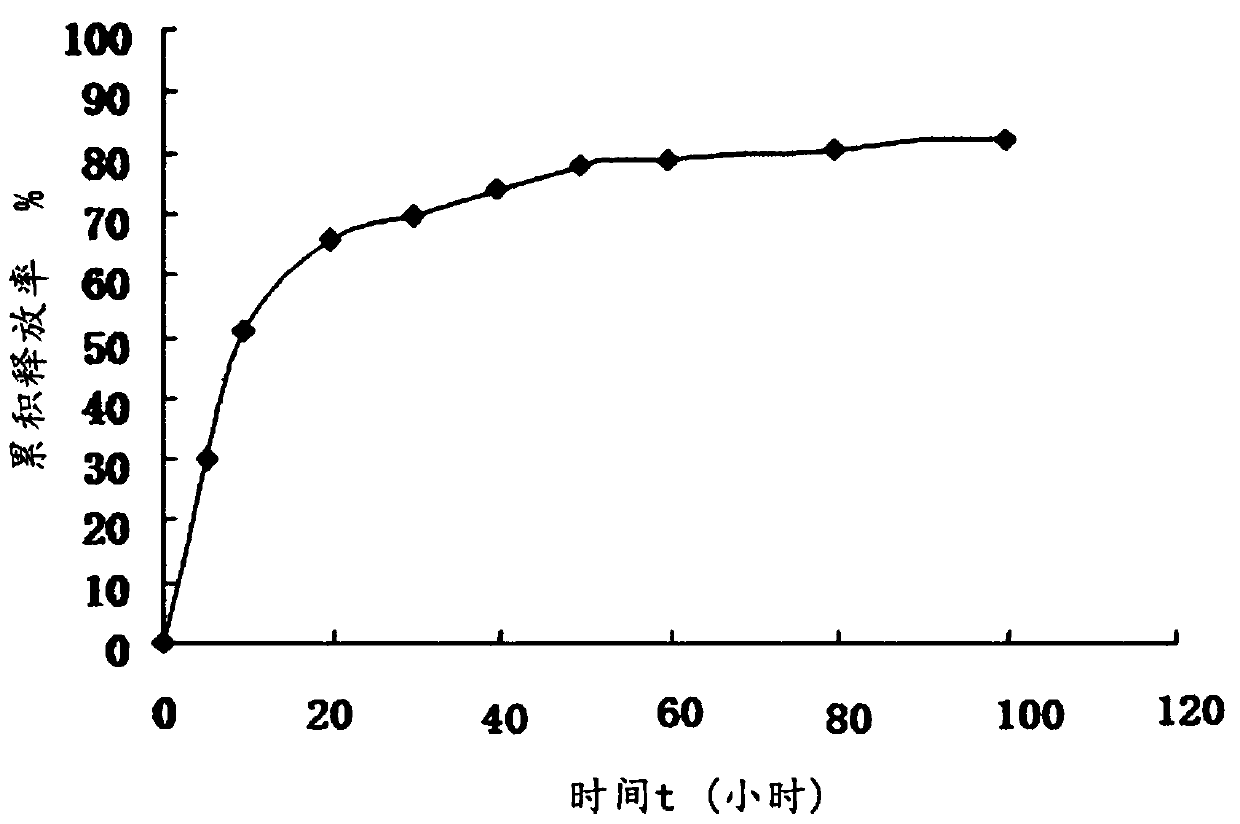

Embodiment 2

[0038] A method for preparing a porous nano-hydroxyapatite sustained-release gel of the present embodiment, the method comprises the following steps:

[0039] Step 1: adding nano-hydroxyapatite powder into water to prepare a hydroxyapatite slurry with a content of 10-40% (w / v);

[0040] Step 2: Mix the hydroxyapatite slurry, the pore-forming agent and the oleic acid in proportion, wherein the weight ratio of the hydroxyapatite slurry to the pore-forming agent is 85:15. Put it in a ball mill for 6-24 hours, and get a uniform suspension after ball milling; the pore-forming agent is carbon powder.

[0041] Step 3: The suspension is added with an organic compounding agent to mix in proportion, and then put into a 50°C water bath to stir and dissolve; the organic compounding agent is a combination of gelatin, gum arabic, chitosan and sodium alginate. The stirring rate of the water bath was 250r / min, and the dissolution time was 5h.

[0042] Step 4: spray-drying and granulating th...

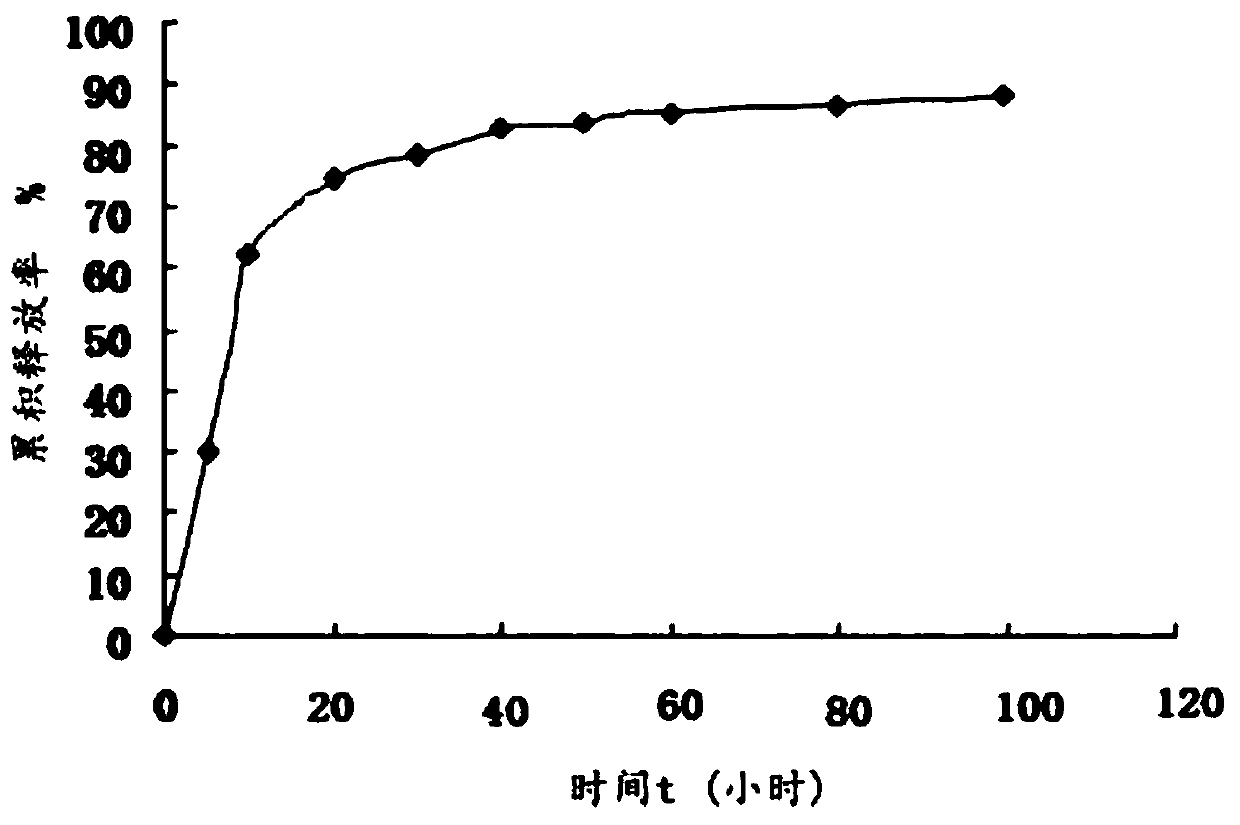

Embodiment 3

[0048] A method for preparing a porous nano-hydroxyapatite sustained-release gel of the present embodiment, the method comprises the following steps:

[0049] Step 1: adding nano-hydroxyapatite powder into water to prepare a hydroxyapatite slurry with a content of 10-40% (w / v);

[0050] Step 2: Mix the hydroxyapatite slurry, the pore-forming agent and the oleic acid in proportion, wherein the weight ratio of the hydroxyapatite slurry to the pore-forming agent is 95:5. Put it in a ball mill for 6-24 hours, and get a uniform suspension after ball milling; the pore-forming agent is carbon powder.

[0051] Step 3: The suspension is added with an organic compounding agent to mix in proportion, and then put into a 50°C water bath to stir and dissolve; the organic compounding agent is a combination of gelatin, gum arabic, chitosan and sodium alginate. The stirring rate of the water bath was 250r / min, and the dissolution time was 5h.

[0052] Step 4: spray-drying and granulating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com