Cerium oxide supported bismuth nano catalyst as well as preparation method and application thereof

A cerium oxide and bismuth nanotechnology, which is applied in the field of cerium oxide-supported bismuth nanocatalyst and its preparation, can solve the problems of formic acid generation rate limitation, sensitivity to applied current density, complex formic acid, etc., achieve excellent stability, short synthesis time, good The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

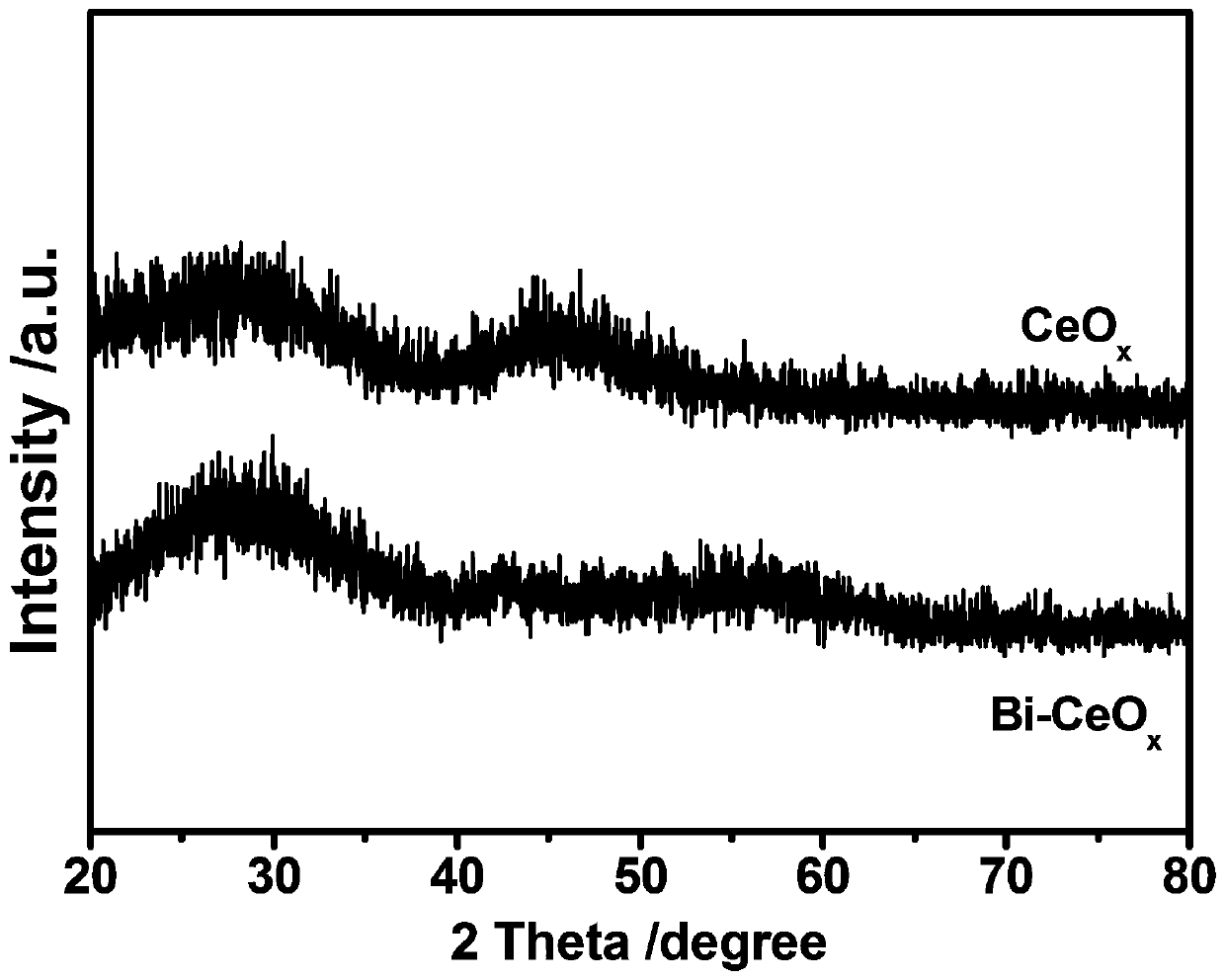

[0039] This embodiment provides a cerium oxide-supported bismuth nanocatalyst and a preparation method thereof. Specifically, the preparation method of the cerium oxide-supported bismuth nanocatalyst includes the following steps:

[0040] (1) 1.5g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in ultrapure water and stirred evenly by ultrasonic waves to obtain solution A;

[0041] (2) Add 400 mg of NaBH to Solution A 4 , stirred evenly, carried out the reduction reaction for 40min, and obtained solution B;

[0042] (3) After the solution B is centrifuged, washed with water and washed with alcohol in sequence, and then dried at a temperature of 60°C, the carrier cerium oxide (CeO x );

[0043] (4) Place 400 mg of carrier cerium oxide in ultrapure water, and stir evenly with ultrasonic waves to obtain solution C, wherein the ultrasonic frequency is 40 kHz;

[0044] (5) Add 1.5g of Bi(NO 3 ) 3 ·5H 2 O, using ultrasonic stirring to obtain solution D, wherein the ultrasonic frequenc...

Embodiment 2

[0049] This embodiment provides a cerium oxide-supported bismuth nanocatalyst and a preparation method thereof. Specifically, the preparation method of the cerium oxide-supported bismuth nanocatalyst includes the following steps:

[0050] (1) 1g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in ultrapure water and stirred evenly by ultrasonic waves to obtain solution A;

[0051] (2) Add 100 mg of NaBH to Solution A 4 , stirred evenly, and carried out the reduction reaction for 10 minutes to obtain solution B;

[0052] (3) After the solution B is centrifuged, washed with water and washed with alcohol in sequence, and then dried at a temperature of 50°C, the carrier cerium oxide (CeO x );

[0053] (4) Place 100 mg of carrier cerium oxide in ultrapure water, and stir evenly with ultrasonic waves to obtain solution C;

[0054] (5) Add 0.5g of Bi(NO 3 ) 3 ·5H 2 O, using ultrasonic stirring to obtain solution D;

[0055] (6) 120mg of Na 2 CO 3 Dissolved in ultrapure water and stir...

Embodiment 3

[0059] This embodiment provides a cerium oxide-supported bismuth nanocatalyst and a preparation method thereof. Specifically, the preparation method of the cerium oxide-supported bismuth nanocatalyst includes the following steps:

[0060] (1) 2g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in ultrapure water and stirred evenly by ultrasonic waves to obtain solution A;

[0061] (2) Add 800 mg of NaBH to solution A 4 , stirred evenly, and carried out the reduction reaction for 60 minutes to obtain solution B;

[0062] (3) After the solution B is centrifuged, washed with water, and washed with alcohol in sequence, and then dried at a temperature of 70°C, the carrier cerium oxide (CeO x );

[0063] (4) Place 800 mg of carrier cerium oxide in ultrapure water, and stir evenly with ultrasonic waves to obtain solution C;

[0064] (5) Add 1.6g of Bi(NO 3 ) 3 ·5H 2 O, using ultrasonic stirring to obtain solution D;

[0065] (6) 640mg of Na 2 CO 3 Dissolved in ultrapure water and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com