Anticorrosive coating material for a concrete base material, and construction method thereof

A technology for concrete substrates and anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the harsh construction conditions of chlorinated polyethylene and silicone coatings, chlorinated rubber pollution of the environment, epoxy resin Easy to pulverize and other problems, achieve the effect of low requirements for construction equipment and construction conditions, improve anti-corrosion performance, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

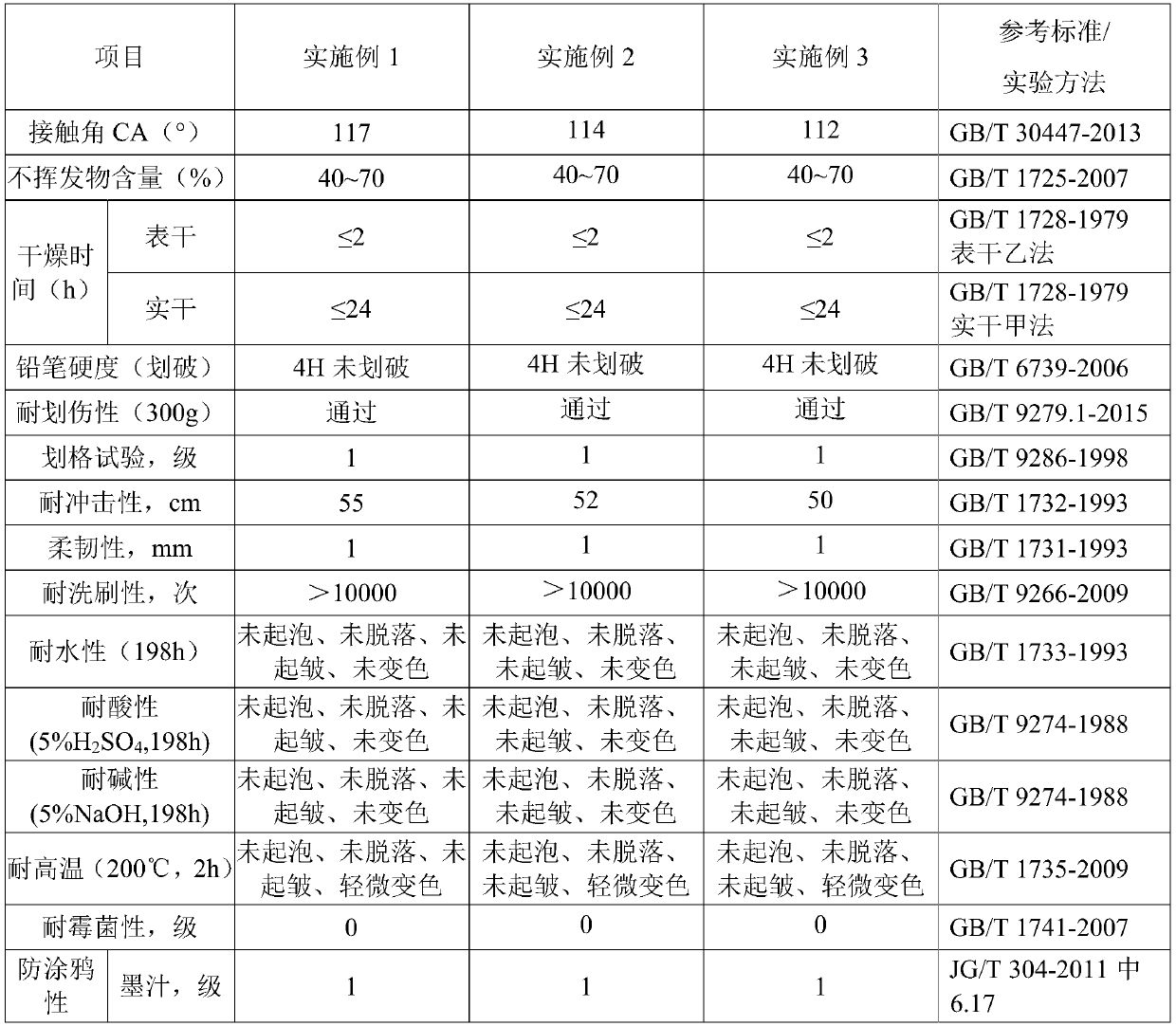

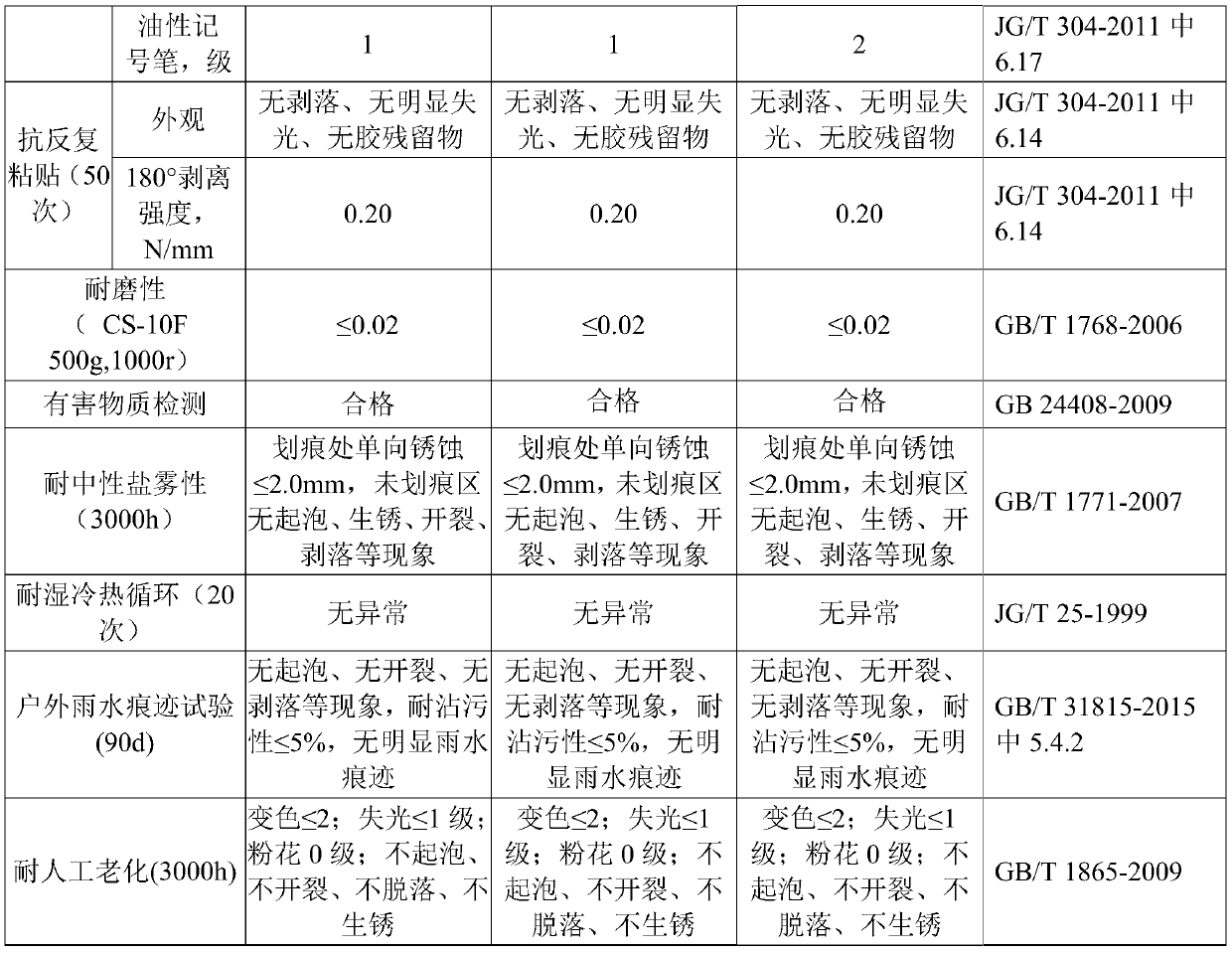

Examples

Embodiment 1

[0033]Embodiment 1 of the present invention provides a kind of anticorrosion coating for concrete substrate, comprises component A and component B, and wherein component A comprises the component of following parts by weight: modified graphene micropowder 0.2 part, fluorocarbon Modified hydroxyl acrylic resin (hydroxyl value 120mg KOH / g) 45 parts, silicone resin (hydroxyl value 50mg KOH / g) 5 parts, drier dibutyltin dilaurate 1 part, benzimidazole anti-mold and anti-algae agent 1 part, 1 part of polyurethane leveling agent, 1 part of acrylate wetting and dispersing agent, 0.5 part of titanium dioxide, 1 part of carbon black, 1 part of defoamer byk-063, 43.3 parts of solvent (solvent is butyl acetate and Cyclohexanone is mixed according to the mass ratio of 1:1); component B includes 50 parts of HDI trimer and 50 parts of solvent (the solvent is butyl acetate and cyclohexanone mixed according to the mass ratio of 1:1); component A The mass ratio to component B is 1:4.

[0034] ...

Embodiment 2

[0041] Embodiment 2 of the present invention provides a kind of anticorrosion coating for concrete base material, comprises component A and component B, and wherein component A comprises the component of following parts by weight: modified graphene micropowder 0.1 part, fluorocarbon Modified hydroxyl acrylic resin (hydroxyl value 115mg KOH / g) 36 parts, silicone resin (hydroxyl value 40mg KOH / g) 4 parts, drier dibutyltin dilaurate 1.5 parts, benzimidazole anti-mold and anti-algae agent 2 parts, 2 parts of polyurethane leveling agent, 2 parts of acrylate wetting and dispersing agent, 1 part of titanium dioxide, 1.5 parts of carbon black, 2 parts of defoamer byk-063, 47.9 parts of solvent (solvent is butyl acetate and Cyclohexanone is mixed according to the mass ratio of 1:1); component B includes 40 parts of HDI trimer, 60 parts of solvent (the solvent is butyl acetate and cyclohexanone mixed according to the mass ratio of 1:1); component A The mass ratio to component B is 1:2. ...

Embodiment 3

[0046] Embodiment 3 of the present invention provides a kind of anticorrosion coating for concrete base material, comprises component A and component B, and wherein component A comprises the component of following parts by weight: modified graphene micropowder 0.5 part, fluorocarbon Modified polyurethane resin (hydroxyl value 125mgKOH / g) 54 parts, silicone resin (hydroxyl value 50mg KOH / g) 6 parts, drier dibutyltin dilaurate 2 parts, benzimidazole anti-mold and anti-algae agent 3 parts , 3 parts of polyurethane leveling agent, 3 parts of acrylate wetting and dispersing agent, 1 part of titanium dioxide, 2 parts of carbon black, 3 parts of defoamer byk-063, 22.5 parts of solvent (solvent is butyl acetate and cyclohexane Ketones are mixed according to the mass ratio of 1:1); component B includes 60 parts of HDI trimer, 40 parts of solvent (the solvent is butyl acetate and cyclohexanone mixed according to the mass ratio of 1:1); component A and group The mass ratio of Part B is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com