Modified ultrafiltration membrane and modification method thereof

An ultrafiltration membrane and modification technology, which is applied in the field of modified ultrafiltration membrane and its modification, can solve the problems such as the decline of ultrafiltration membrane separation performance, the shortened service life of ultrafiltration membrane, and the decline of sewage treatment capacity, so as to achieve good resistance The effect of pollution performance, good hydrophilicity, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

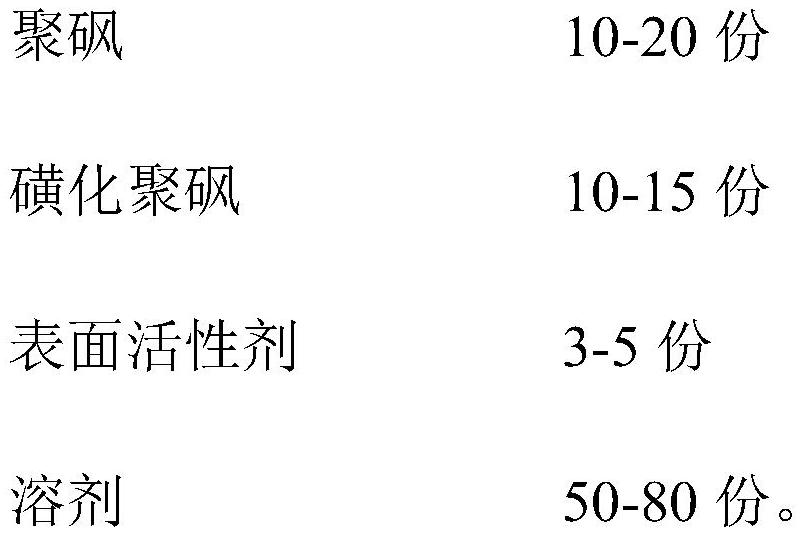

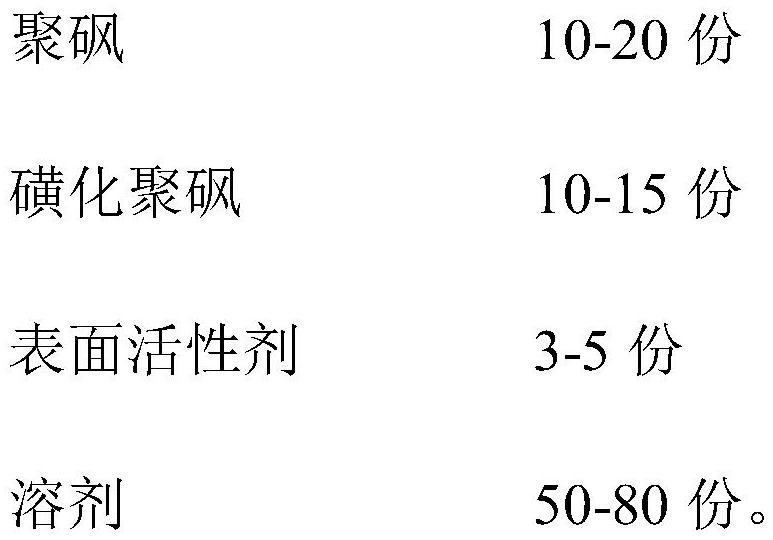

Method used

Image

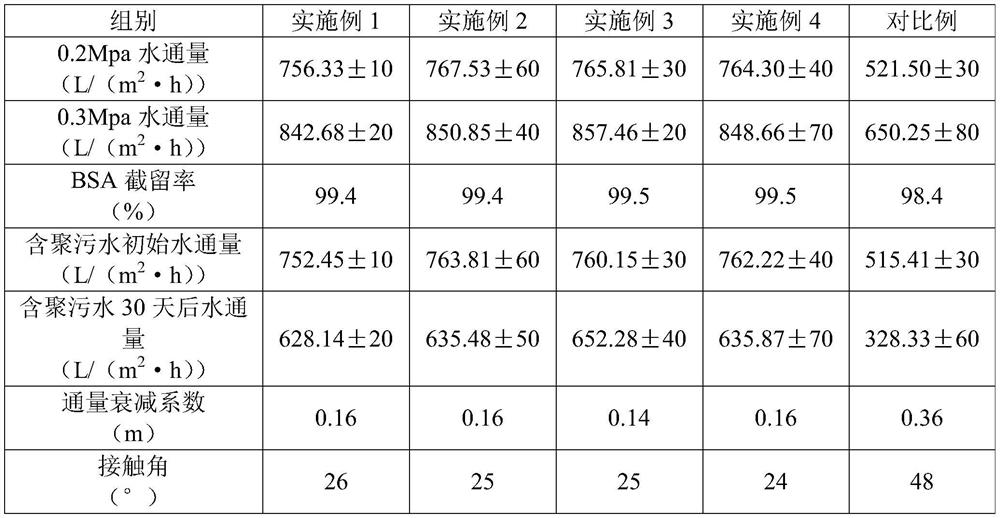

Examples

Embodiment 1

[0028] According to the mass ratio of 10:10:3:50, mix polysulfone, sulfonated polysulfone, Tween 20 and N,N-dimethylformamide, stir for 30 minutes, and pass the mixed solution through a 0.2 μm microporous membrane for filtration. Filtrate, keep the filtered solution at -0.1Mpa vacuum, keep it at room temperature, let it stand for degassing for 5min, and obtain the casting solution;

[0029] The defoamed casting solution is evenly coated on the non-woven fabric, and the flat film scraping machine scrapes the film to form a scraped film with a thickness of 200 μm. After scraping the film, it is evaporated at normal temperature and pressure for 1 min, and the scraped film is soaked in a mass concentration of Rinse in 20% aqueous solution of N,N-dimethylformamide for 2 minutes to obtain a flat ultrafiltration membrane;

[0030] Soak the above-mentioned flat ultrafiltration membrane again in an aqueous solution of methacryloyloxyethylalkyldimethylammonium bromide with a mass concen...

Embodiment 2

[0033] According to the mass ratio of 20:15:5:80, mix polysulfone, sulfonated polysulfone, Tween 80 and N,N-dimethylacetamide, stir for 30 minutes, and pass the mixed solution through a 0.2 μm microporous membrane for filtration. Filtrate, keep the filtered solution at -0.1Mpa vacuum, keep it at room temperature, let it stand for degassing for 5min, and obtain the casting solution;

[0034] The defoamed casting solution is evenly coated on the non-woven fabric, and the film is scraped by a flat film scraping machine. The thickness of the scraped film is 200 μm. After scraping the film, it is evaporated at normal temperature and pressure for 2 minutes. Rinse in 20% aqueous solution of N,N-dimethylacetamide for 2 minutes to obtain a flat ultrafiltration membrane;

[0035] Soak the above-mentioned flat ultrafiltration membrane again in an aqueous solution of methacryloyloxyethylalkyldimethylammonium bromide with a mass concentration of 30%, and at the same time irradiate with ult...

Embodiment 3

[0038] According to the mass ratio of 15:10:4:60, mix polysulfone, sulfonated polysulfone, polyoxyethylene octylphenol ether and N-methylpyrrolidone, stir for 30 minutes, and pass the mixed solution through a 0.2 μm microporous membrane for filtration. Filtrate, keep the filtered solution at -0.1Mpa vacuum, keep it at room temperature, let it stand for degassing for 5min, and obtain the casting solution;

[0039] The defoamed casting solution is evenly coated on the non-woven fabric, and the flat film scraping machine scrapes the film to form a scraped film with a thickness of 200 μm. After scraping the film, it is evaporated at normal temperature and pressure for 1 min, and the scraped film is soaked in a mass concentration of Rinse in 20% aqueous solution of N-methylpyrrolidone for 2 minutes to obtain a flat ultrafiltration membrane;

[0040] Soak the above-mentioned flat ultrafiltration membrane again in an aqueous solution of methacryloyloxyethylalkyldimethylammonium bromi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com