Rubber blank and preparation method thereof

A green body and rubber technology, applied in the field of rubber green body and its preparation, can solve the problems of insufficient corrosion resistance and insufficient life, and achieve the effects of simple method, excellent corrosion resistance and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

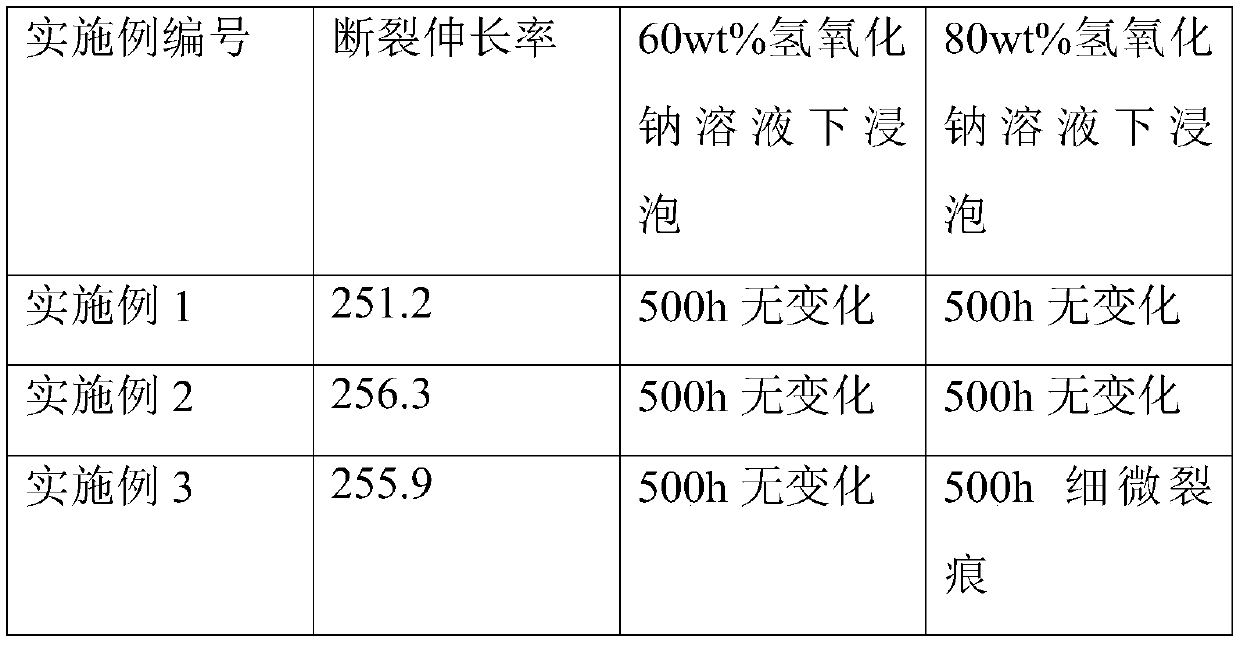

Examples

preparation example Construction

[0013] The invention provides a kind of preparation method of rubber body, and described preparation method comprises:

[0014] (1) Natural rubber, nitrile rubber, fluorosilicone rubber, potassium pyrrolidone carboxylate, mica powder, aluminum hydroxide, zinc oxide, glycerin, triethanolamine, paraffin, magnesium stearate, antioxidant MB, polyurethane, vulcanization accelerator The agent and the reinforcing filler are mixed, and the mixture M is obtained after ball milling;

[0015] (2) masticating the mixture M until the rubber N is masticated;

[0016] (3) The plasticized rubber N is kneaded and vulcanized to obtain a rubber body.

[0017] In a preferred embodiment of the present invention, in order to further improve the corrosion resistance of the prepared rubber, 15-25 parts of natural rubber, 5-10 parts of nitrile rubber, 15-30 parts of fluorosilicone rubber, pyrrolidone carboxylic acid 2-7 parts of potassium, 4-7 parts of mica powder, 1-5 parts of aluminum hydroxide, 1...

Embodiment 1

[0029] Natural rubber, nitrile rubber, fluorosilicone rubber, potassium pyrrolidone carboxylate, mica powder, aluminum hydroxide, zinc oxide, glycerin, triethanolamine, paraffin, magnesium stearate, antioxidant MB, polyurethane, vulcanization accelerator and supplement Mix strong fillers and ball mill (temperature 50°C, rotation speed 300rpm, time 10min) to obtain mixture M; masticate mixture M (temperature 70°C, time 2min), wait until rubber N is plasticized; Mix rubber N for mixing (mixing includes the first-stage mixing and second-stage mixing in sequence; the conditions for the first-stage mixing include: the temperature is 60°C, and the time is 3h; the conditions for the second-stage mixing include: the temperature is 110°C , the time is 30 min), vulcanization (the temperature is 150° C., the pressure is 6 MPa, the time is 10 min) to obtain the rubber body. Among them, 15g of natural rubber, 5g of nitrile rubber, 15g of fluorosilicone rubber, 2g of potassium pyrrolidone c...

Embodiment 2

[0031] Natural rubber, nitrile rubber, fluorosilicone rubber, potassium pyrrolidone carboxylate, mica powder, aluminum hydroxide, zinc oxide, glycerin, triethanolamine, paraffin, magnesium stearate, antioxidant MB, polyurethane, vulcanization accelerator and supplement Mix strong fillers and ball mill (temperature 70°C, rotation speed 350rpm, time 15min) to obtain mixture M; masticate mixture M (temperature 90°C, time 5min), wait until rubber N is plasticized; Mix rubber N for mixing (mixing includes one-stage mixing and two-stage mixing in sequence; the conditions for one-stage mixing include: the temperature is 80°C, and the time is 7h; the conditions for second-stage mixing include: the temperature is 120°C , the time is 60 min), vulcanization (the temperature is 210° C., the pressure is 8 MPa, the time is 15 min) to obtain the rubber green body. Among them, 25g of natural rubber, 10g of nitrile rubber, 30g of fluorosilicone rubber, 7g of potassium pyrrolidone carboxylate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com