Preparation method of super-hydrophobic polyester film

A water polyester and super-hydrophobic technology, which is applied in the field of preparation of super-hydrophobic polyester films, can solve the problems of not achieving super-hydrophobic performance, and achieve the effects of excellent super-hydrophobic performance, reducing surface energy and improving hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

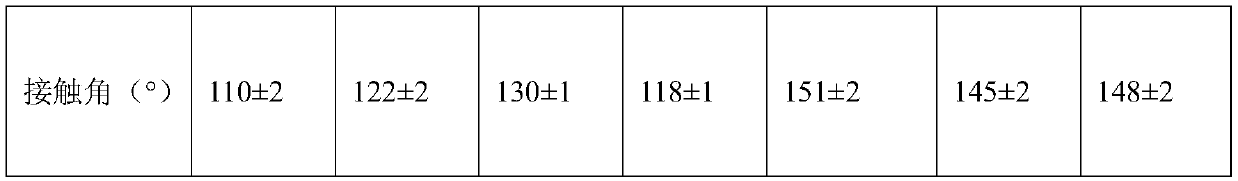

Embodiment 1

[0029] Use terephthalic acid, ethylene glycol, catalyst, and fluorinated diol (2,2,3,3-tetrafluoro-1,4-butanediol) as raw materials to stir into a uniform slurry, then add it to the reactor for esterification , the molar ratio of ethylene glycol to terephthalic acid is 1.3; the amount of fluorine-containing compound added is 10%, the catalyst is ethylene glycol, and the amount of antimony used is 0.03% of the quality of terephthalic acid. The esterification reaction is carried out under pressure in a nitrogen atmosphere, the pressure is controlled at 0.25MPa, the temperature is at 260°C, and the esterification water distillation amount reaches more than 85% of the theoretical value, which is regarded as the end point of the esterification reaction.

[0030] Heat up and vacuumize to enter the low vacuum stage. When the vacuum degree reaches below 100Kpa, the temperature is controlled at 285°C, and the polycondensation reaction starts. The reaction end point is controlled accordi...

Embodiment 2

[0034] Use terephthalic acid, ethylene glycol, catalyst, fluorinated diol (1H, 1H, 9H, 9H-perfluoro-nonanediol) as raw materials to stir into a uniform slurry, then add it to the reactor for esterification reaction, B The molar ratio of diol to terephthalic acid is 1.7; the addition amount of fluorine-containing compound is 2%, and the catalyst is antimony acetate, and the dosage is 0.01% of the mass of the terephthalic acid. The esterification reaction is carried out under pressure in a nitrogen atmosphere, the pressure is controlled at 0.3 MPa, the temperature is at 265° C., and the esterification water distillation amount reaches more than 85% of the theoretical value, which is regarded as the end point of the esterification reaction.

[0035] Heat up and vacuumize to enter the low vacuum stage. When the vacuum degree reaches below 100Kpa, the temperature is controlled at 290°C, and the polycondensation reaction starts. The reaction end point is controlled according to the s...

Embodiment 3

[0039] Use terephthalic acid, ethylene glycol, catalyst, fluorinated diol (1H, 1H, 9H, 9H-perfluoro-nonanediol) as raw materials to stir into a uniform slurry, then add it to the reactor for esterification reaction, B The molar ratio of diol to terephthalic acid is 1.1; the amount of fluorine-containing compound added is 20%, and the catalyst is antimony trioxide. The amount is 0.04% of the quality of terephthalic acid; Pressure reaction, the pressure is controlled at 0.2MPa, the temperature is at 255°C, and the distilled amount of esterification water reaches more than 85% of the theoretical value, which is regarded as the end point of the esterification reaction.

[0040] Heat up and vacuumize to enter the low vacuum stage. When the vacuum degree reaches below 100Kpa, the temperature is controlled at 280°C, and the polycondensation reaction starts. The end point of the reaction is controlled according to the stirring power. pellets to obtain fluorine-containing PET chips.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com