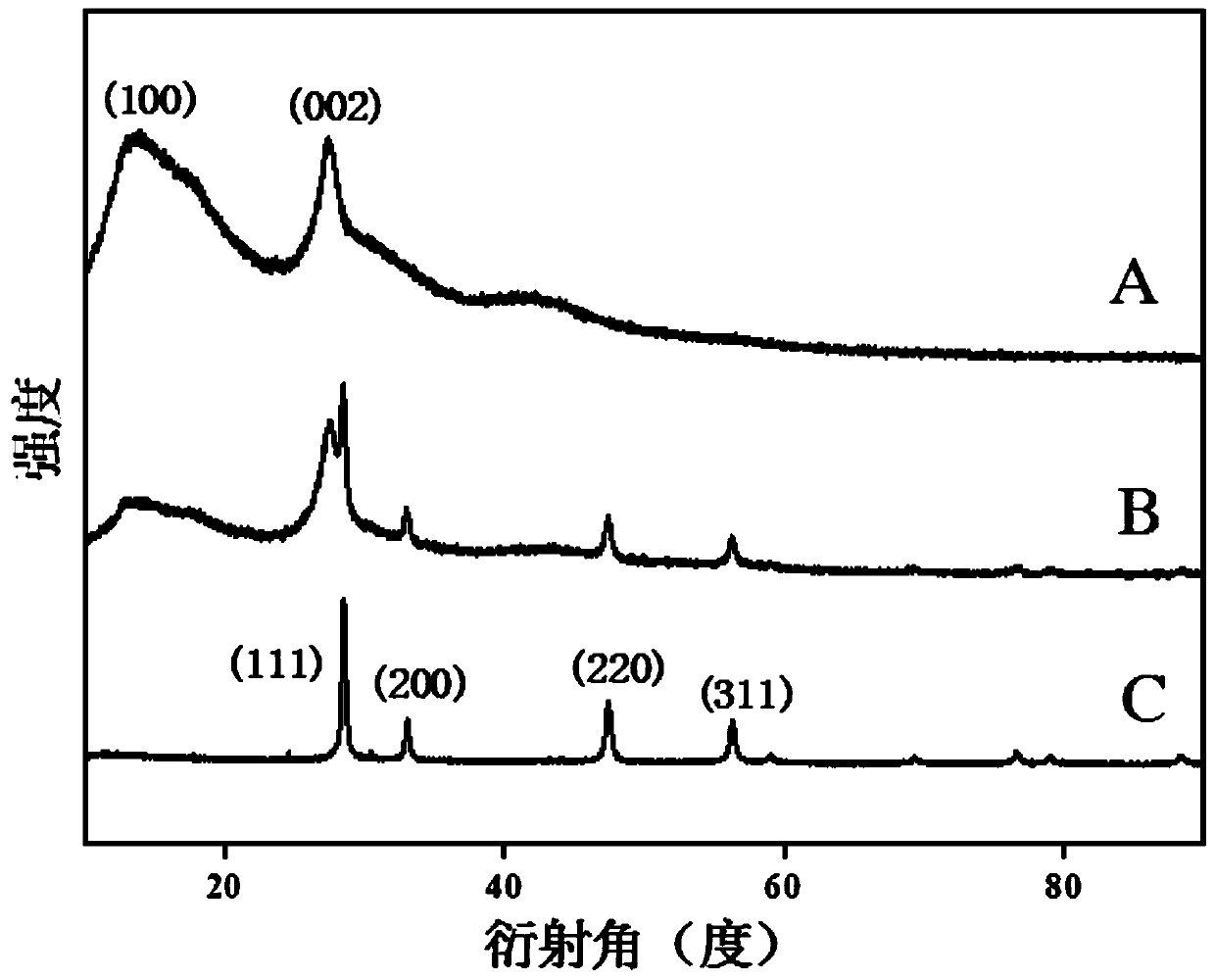

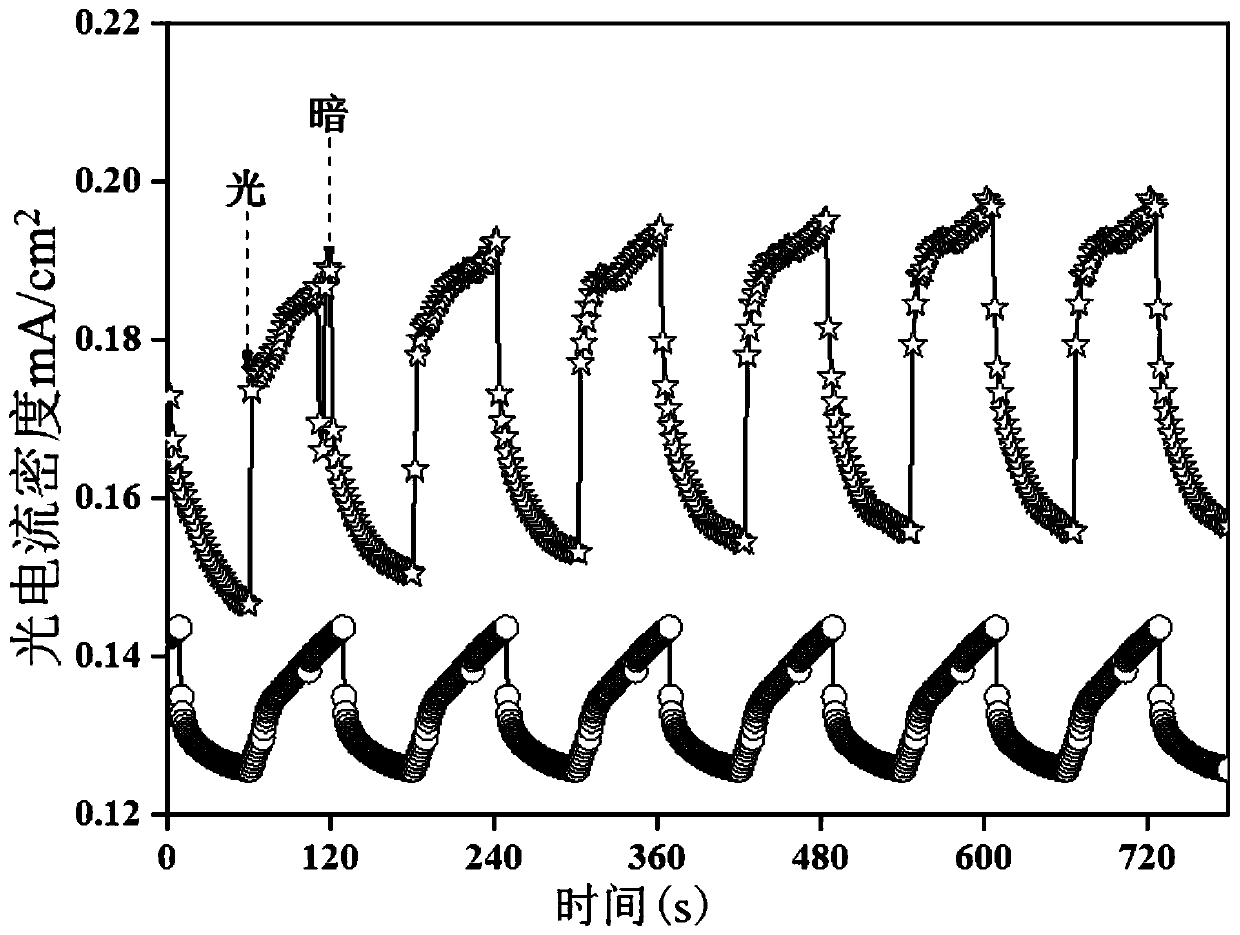

Preparation method of cerium dioxide nanosphere-carbon nitride composite visible light catalyst

A technology of ceria and nanospheres, which is applied in the field of preparation of carbon nitride composite visible light catalysts, can solve the problems of easy recombination of photogenerated electrons and holes, and achieve the goal of improving photocatalytic activity, degradation rate and photocatalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Embodiment 1: This embodiment is a preparation method of ceria nanosphere-carbon nitride composite visible light catalyst, which is specifically completed according to the following steps:

[0023] 1. Preparation of carbon nitride: ①, dry grinding: dry the urea to obtain dried urea, then place it in a mortar for grinding to obtain urea powder; ② sintering: place the urea powder in an alumina crucible, and using aluminum foil paper to seal the alumina crucible to obtain a sealed alumina crucible containing the mixed powder, and placing the sealed alumina crucible filled with the mixed powder in a muffle furnace for sintering to obtain carbon nitride;

[0024] 2. Preparation of ceria hollow nanospheres:

[0025] ①. Preparation of silica powder: add ammonia water and ethanol to deionized water, stir and mix well, then add tetraethyl orthosilicate drop by drop, and stir for 1h to 2h, centrifuge to obtain a solid product, at a temperature of 60 ~ Dry the solid product to co...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is: the specific operation of the drying treatment described in step ① is as follows: place in an oven, and dry at a temperature of 40° C. to 80 for 6 hours to 24 hours. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the specific process of sintering described in step ② is as follows: first, the muffle furnace is heated at a rate of 3°C / min to 5°C / min. The internal temperature is raised from room temperature to 450°C to 700°C, and sintered at a temperature of 450°C to 700°C for 2h to 6h, and then the temperature is lowered to room temperature. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com