Preparation method of multistage sample injection micro-fluidic chip for synthesizing Ag/Ag2S/CdS heterojunction

A microfluidic chip and heterojunction technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of insufficiency, agglomeration, difficulties in nanomaterials, etc., and improve the photocurrent signal. , uniform size, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

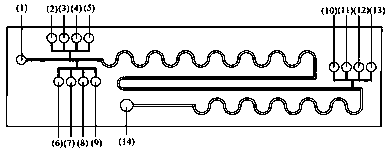

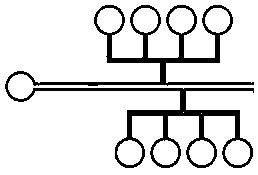

[0030] Preparation of PDMS microfluidic chip: the injection port (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) The radius is 750 μm, the width of the reaction channel is 300 μm, and the width of the injection channel is 100 μm. The height of the microfluidic chip is 100 μm.

Embodiment 2

[0032] Preparation of PDMS microfluidic chip: the injection port (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) The radius is 750 μm, the width of the reaction channel is 350 μm, and the width of the injection channel is 200 μm. The height of the microfluidic chip is 200 μm.

Embodiment 3

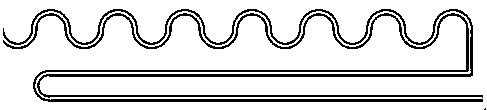

[0034] Synthesis of Ag / Ag Based on Multi-stage Injection Microfluidic Chip 2 Application of S / CdS heterojunction: The oil phase is injected into the chip channel from the injection port (1) at a flow rate of 30 μL / min, and 2 mmol / L cadmium chloride aqueous solution contains 24 mmol / L 3-mercaptopropionic acid The oil phase was cut into micro-droplets from the injection port (2) at a flow rate of 20 μL / min, and 2 mmol / L sodium sulfide aqueous solution was injected from the injection port (6) at a flow rate of 20 μL / min. The channel meets the Cd source micro-droplets to form CdS micro-droplets and enter the mixed reaction area; then inject 4 mmol / L silver nitrate aqueous solution from the injection port (10) into the channel at a flow rate of 20 μL / min and CdS microdroplets meet to form Ag 2 S / CdS micro-droplets enter the mixed reaction area and collect Ag 2 Excess silver ions on the surface of S / CdS heterojunction were irradiated with 385 nm UV lamp for 60 min to obtain Ag / Ag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com