Preparation method for making recycled material from domestic kitchen waste

A technology for kitchen waste and manufacturing equipment, which is applied in the fields of biofuels, chemical instruments and methods, and solid waste removal, etc., can solve the problems affecting the quality and use of pellet feed reuse materials, small bulk density and breaking strength, and reduce pressure. consumption and other problems, to shorten the preparation time, improve the exudation rate, and speed up the discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

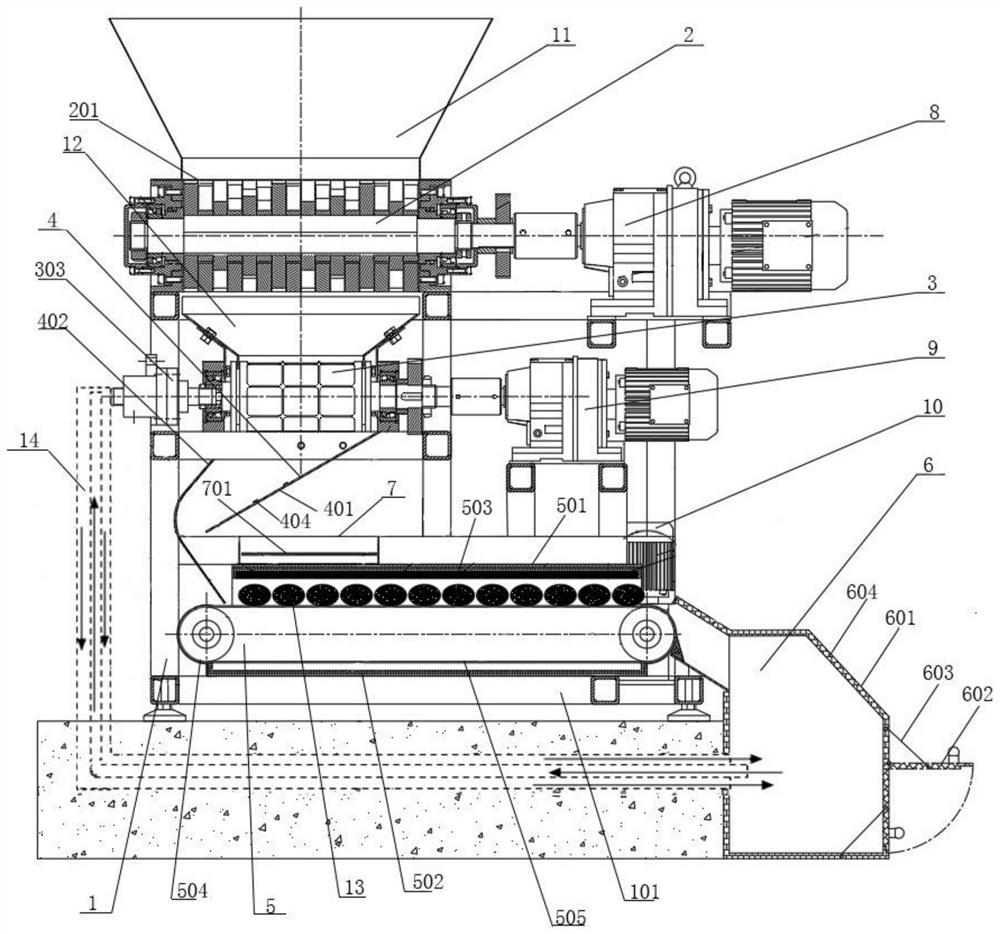

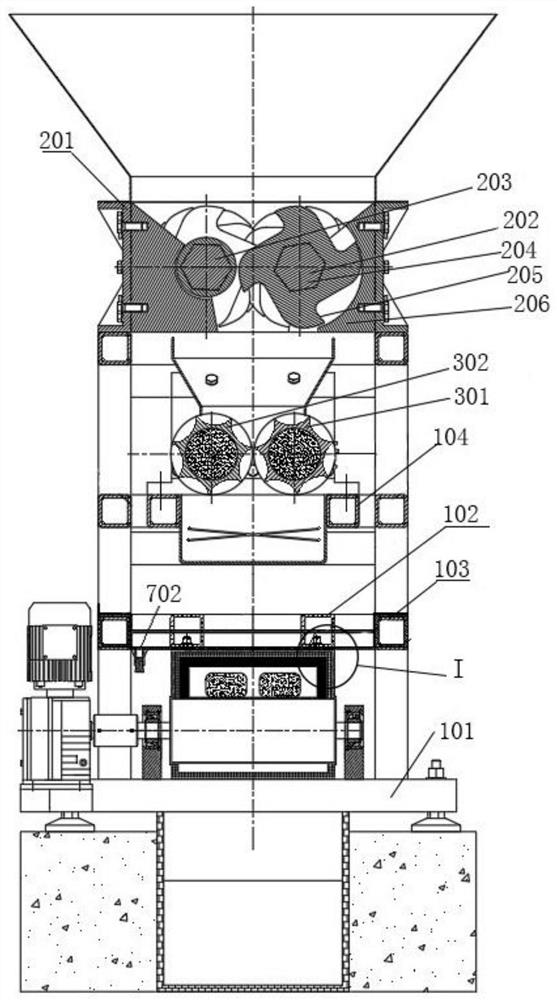

[0041] Example 1, such as figure 1 , figure 2 As shown, the preparation method for making reused materials from domestic kitchen waste comprises the following steps:

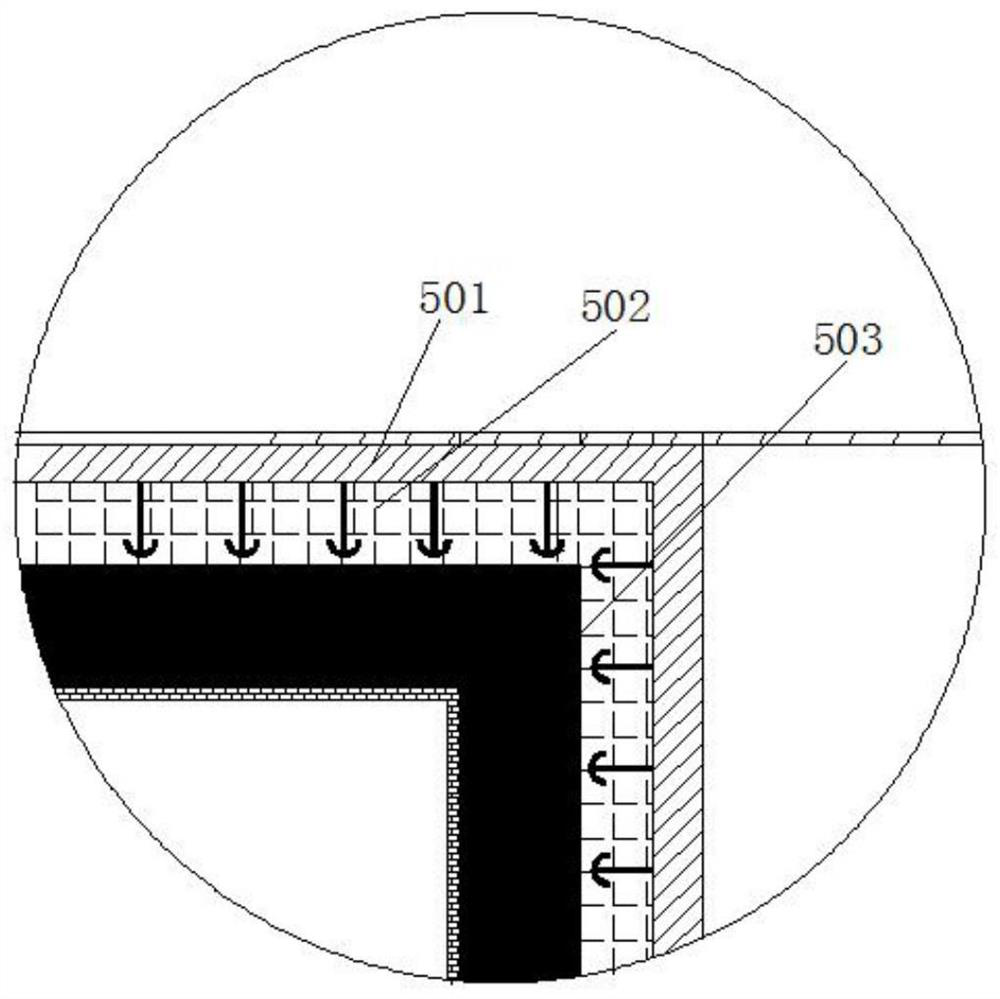

[0042] Step 1 Obtain the following manufacturing equipment to prepare domestic kitchen waste. The manufacturing equipment is fixedly installed on the frame 1, and the frame 1 is placed on the workbench on the ground. The manufacturing equipment includes a crusher 2 from top to bottom , extrusion molding machine 3, blanking guide mechanism 4 and drying mechanism 5, also includes waste heat dry ember cavity 6 arranged on one side of the workbench and connected with drying mechanism 5 through a flexible hose, the upper and lower ends of the crusher 2 Both are open ends, and the upper end is connected to the first feeding hopper 11. The crusher 2 is powered by the first motor 8, and is used to crush and mix domestic kitchen waste, straw powder and binder to form usable materials. A second feed hopper 12 is arrang...

Embodiment 2

[0058] Example 2, the manufacturing equipment used is the same as that of Example 1, and the following parameters are adjusted to prepare

[0059] In step 2, the temperature of waste heat flue gas is 100°C, preheating for 5 minutes;

[0060] Step 3: The molding extruder is evenly heated and preheated for 5 minutes;

[0061] Step 4: Set the heating temperature of the thermal radiation source to 280°C, and preheat the material transfer device for 1 minute;

[0062] Step 5 Domestic kitchen waste and straw powder are mixed in a ratio of 5:1, 6% of modified starch is added, and crushed;

Embodiment 3

[0063] Example 3, the manufacturing equipment used is the same as that of Example 1, and the following parameters are adjusted to prepare

[0064] In step 2, the temperature of waste heat flue gas is 200°C, preheating for 10 minutes;

[0065] Step 3: The molding extruder is evenly heated, and preheated for 4 minutes;

[0066] Step 4: Set the heating temperature of the thermal radiation source to 200°C, and preheat the material transfer device for 3 minutes;

[0067] Step 5 Domestic kitchen waste and straw powder are mixed in a ratio of 4:1, 5% of modified starch is added, and crushed;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com